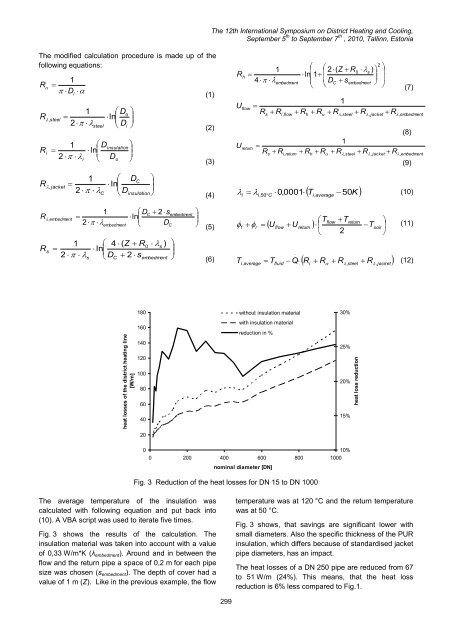

The <str<strong>on</strong>g>12th</str<strong>on</strong>g> <str<strong>on</strong>g>Internati<strong>on</strong>al</str<strong>on</strong>g> <str<strong>on</strong>g>Symposium</str<strong>on</strong>g> <strong>on</strong> <strong>District</strong> <strong>Heating</strong> <strong>and</strong> <strong>Cooling</strong>,September 5 th to September 7 th , 2010, Tallinn, Est<strong>on</strong>iaThe modified calculati<strong>on</strong> procedure is made up of thefollowing equati<strong>on</strong>s:RRR1 ,steeliD i12 steel1 D ln2 i D Doln Diinsulati<strong>on</strong>o(1)(2)(3)RUUhflow14 returnR RsR Rsembedmenti,flowi,return 2(Z R sln1 DC sembedment R Rh R Rh1 R,steel1 R,steel0) R R2 ,jacket,jacket R R(7),embedment(8),embedment(9)R,jacket12 C D ln DCinsulati<strong>on</strong>(4) i i , 50C0 ,0001T i , average 50K(10)RR,embedments12 embedment DlnC 2sD1 4 ( Z R0 s) ln2 s DC 2 sembedmentembedmentC(5)(6)TflowTreturnf r Uflow UreturnTsoil (11) 2 Ti, average Tfluid QRi R R,steel R,jacket(12)heat losses of the district heating line[W/m]18016014012010080604020without insulati<strong>on</strong> materialwith insulati<strong>on</strong> materialreducti<strong>on</strong> in %30%25%20%15%heat loss reducti<strong>on</strong>010%0 200 400 600 800 1000nominal diameter [DN]Fig. 3 Reducti<strong>on</strong> of the heat losses for DN 15 to DN 1000The average temperature of the insulati<strong>on</strong> wascalculated with following equati<strong>on</strong> <strong>and</strong> put back into(10). A VBA script was used to iterate five times.Fig. 3 shows the results of the calculati<strong>on</strong>. Theinsulati<strong>on</strong> material was taken into account with a valueof 0,33 W/m*K (λ embedment ). Around <strong>and</strong> in between theflow <strong>and</strong> the return pipe a space of 0,2 m for each pipesize was chosen (s embedment ). The depth of cover had avalue of 1 m (Z). Like in the previous example, the flowtemperature was at 120 °C <strong>and</strong> the return temperaturewas at 50 °C.Fig. 3 shows, that savings are significant lower withsmall diameters. Also the specific thickness of the PURinsulati<strong>on</strong>, which differs because of st<strong>and</strong>ardised jacketpipe diameters, has an impact.The heat losses of a DN 250 pipe are reduced from 67to 51 W/m (24%). This means, that the heat lossreducti<strong>on</strong> is 6% less compared to Fig.1.299

The <str<strong>on</strong>g>12th</str<strong>on</strong>g> <str<strong>on</strong>g>Internati<strong>on</strong>al</str<strong>on</strong>g> <str<strong>on</strong>g>Symposium</str<strong>on</strong>g> <strong>on</strong> <strong>District</strong> <strong>Heating</strong> <strong>and</strong> <strong>Cooling</strong>,September 5 th to September 7 th , 2010, Tallinn, Est<strong>on</strong>iaSince the use of an insulating backfill is more efficientwith huge diameters, a DN 700 pipe was chosen for anexample scenario. An annual average for the flow <strong>and</strong>return temperature was taken into account. For thecalculati<strong>on</strong> of the required backfill volume in theembedment, 0.2 m space in every directi<strong>on</strong> of the pipeswas estimated. It is important for the calculati<strong>on</strong> to take<strong>on</strong>ly the additi<strong>on</strong>al costs into account. That means theprice difference between cable s<strong>and</strong> <strong>and</strong> the insulati<strong>on</strong>material including the transportati<strong>on</strong> costs.A comm<strong>on</strong> value of 6% was chosen for the requiredrate of return (i).The net present value C 0 was calculated with thefollowing equati<strong>on</strong>:CTt0 I (R t) (1 i)t 1(13)The internal rate of return shown in Fig. 4 wascalculated with the IRR- functi<strong>on</strong> in Excel.Table 1 Scenario for insulati<strong>on</strong> materialParameter Value UnitLength of the districtheating line:5000 mNominal diameter: DN 700Average flowtemperature:Average returntemperature:Annual hours ofoperati<strong>on</strong>:Heat price (at the time ofthe invest):Required volume ofinsulati<strong>on</strong> material:95 °C50 °C8760 h15 €/MWh th1.85 m 3Additi<strong>on</strong>al specific costs: 16 - 17 €/m 3Required volume for thewhole line:Heat loss with use of thematerial:Heat loss without use ofthe material:9250 m 369.6 W/m90.7 W/mEnergy savings: 23.3 %Annual savings of thewhole line:924 MWh thAdditi<strong>on</strong>al investment (I): 148,000 – 157,000 €Required rate of return: 6.0 %Time of cash flow: 20 anet present value (20 years) [€]60,00050,00040,00030,00020,00016 €/m 3 17 €/m 316 €/m 3NPV10,000internal17 €/m 3rate ofreturn00.0% 1.0% 2.0% 3.0%growth rate of the heat price10.0%8.0%6.0%4.0%2.0%0.0%Fig. 4 NPV <strong>and</strong> IRR of the scenario defined in Table 1depending <strong>on</strong> the additi<strong>on</strong>al specific costs of the insulati<strong>on</strong>material.The results in Fig. 4 show, that the additi<strong>on</strong>al specificcosts should be below 17 €/m 3 in order to get a positivevalue spread, assumed that the required rate of returnis 6 %. A reducti<strong>on</strong> of specific costs of 5% (16 €/m 3 )results in an increase of the value spread by 1%. Thenet present value after 20 years rises about 10,000 €.The growth rate of the heat price is difficult to predict,but has an important influence within the given periodof 20 years. Presumably the heat price is mainlyinfluenced by emissi<strong>on</strong> trading, governmental subsidies<strong>and</strong> the development of the fossil fuel price.Other scenarios may estimate higher growth rates, butin order to get realistic results, the rate was varied from0% to 3,5%.Table 2 gives an example of materials with low heatc<strong>on</strong>ductivity that could be interesting to use as backfill.It is obvious to look for natural products, because of theprice <strong>and</strong> envir<strong>on</strong>mental regulati<strong>on</strong>s.internal rate of returnAnnual growth rate ofthe heat price:0 – 3.5 %300

- Page 1:

12th Inter

- Page 5 and 6:

The 12th I

- Page 7 and 8:

The 12th I

- Page 10 and 11:

The 12th I

- Page 12 and 13:

The 12th I

- Page 14 and 15:

For the case of parallel buried pip

- Page 16 and 17:

The 12th I

- Page 18 and 19:

The 12th I

- Page 20 and 21:

The 12th I

- Page 22 and 23:

The 12th I

- Page 24 and 25:

The 12th I

- Page 26 and 27:

The 12th I

- Page 28 and 29:

The 12th I

- Page 30 and 31:

The 12th I

- Page 32 and 33:

The 12th I

- Page 34 and 35:

The 12th I

- Page 36 and 37:

The 12th I

- Page 38 and 39:

The 12th I

- Page 40 and 41:

The 12th I

- Page 42 and 43:

The 12th I

- Page 44 and 45:

The 12th I

- Page 46 and 47:

The 12th I

- Page 48 and 49:

The 12th I

- Page 50 and 51:

The 12th I

- Page 52 and 53:

The 12th I

- Page 54 and 55:

The 12th I

- Page 56 and 57:

The 12th I

- Page 58 and 59:

The 12th I

- Page 60 and 61:

The 12th I

- Page 62 and 63:

The 12th I

- Page 64 and 65:

The 12th I

- Page 66 and 67:

The 12th I

- Page 68 and 69:

The 12th I

- Page 70 and 71:

The 12th I

- Page 72 and 73:

The 12th I

- Page 74 and 75:

The 12th I

- Page 76 and 77:

The 12th I

- Page 78 and 79:

The 12th I

- Page 80 and 81:

The 12th I

- Page 82 and 83:

The 12th I

- Page 84 and 85:

The 12th I

- Page 86 and 87:

The 12th I

- Page 88 and 89:

The 12th I

- Page 90 and 91:

The 12th I

- Page 92 and 93:

The 12th I

- Page 94 and 95:

The 12th I

- Page 96 and 97:

The 12th I

- Page 98 and 99:

the street the more shallow the sha

- Page 100 and 101:

The 12th I

- Page 102 and 103:

The 12th I

- Page 104 and 105:

The 12th I

- Page 106 and 107:

The 12th I

- Page 108 and 109:

The 12th I

- Page 110 and 111:

P-1P-4P-9P-7E-5P-14P-8The 1

- Page 112 and 113:

The 12th I

- Page 114 and 115:

The 12th I

- Page 116 and 117:

The 12th I

- Page 118 and 119:

The 12th I

- Page 120 and 121:

The 12th I

- Page 122 and 123:

The 12th I

- Page 124 and 125:

The 12th I

- Page 126 and 127:

The 12th I

- Page 128 and 129:

The 12th I

- Page 130 and 131:

The 12th I

- Page 132 and 133:

The 12th I

- Page 134 and 135:

The 12th I

- Page 136 and 137:

The 12th I

- Page 138 and 139:

to heating costs of 14,5 ct/kWh. Th

- Page 140 and 141:

The 12th I

- Page 142 and 143:

The 12th I

- Page 144 and 145:

The 12th I

- Page 146 and 147:

The 12th I

- Page 148 and 149:

academic access is facilitated as t

- Page 150 and 151:

The 12th I

- Page 152 and 153:

The 12th I

- Page 154 and 155:

The 12th I

- Page 156 and 157:

The 12th I

- Page 158 and 159:

The 12th I

- Page 160 and 161:

The 12th I

- Page 162 and 163:

1. CHP system operation in A2. Ther

- Page 164 and 165:

The 12th I

- Page 166 and 167:

is covered by operating HOB. In oth

- Page 168 and 169:

The 12th I

- Page 170 and 171:

The 12th I

- Page 172 and 173:

The 12th I

- Page 174 and 175:

The 12th I

- Page 176 and 177:

The 12th I

- Page 178 and 179:

The 12th I

- Page 180 and 181:

The 12th I

- Page 182 and 183:

The 12th I

- Page 184 and 185:

The 12th I

- Page 186 and 187:

The 12th I

- Page 188 and 189:

The 12th I

- Page 190 and 191:

The 12th I

- Page 192 and 193:

The 12th I

- Page 194 and 195:

The 12th I

- Page 196 and 197:

produce heat and electricity. Fluct

- Page 198 and 199:

The 12th I

- Page 200 and 201:

The 12th I

- Page 202 and 203:

The 12th I

- Page 204 and 205:

The 12th I

- Page 206 and 207:

The 12th I

- Page 208 and 209:

The 12th I

- Page 210 and 211:

To assure that the temperatures mea

- Page 212 and 213:

The 12th I

- Page 214 and 215:

The 12th I

- Page 216 and 217:

The 12th I

- Page 218 and 219:

The 12th I

- Page 220 and 221:

production and provide for marginal

- Page 222 and 223:

The 12th I

- Page 224 and 225:

The 12th I

- Page 226 and 227:

The 12th I

- Page 228 and 229:

The 12th I

- Page 230 and 231:

The 12th I

- Page 232 and 233:

The 12th I

- Page 234 and 235:

The 12th I

- Page 236 and 237:

The 12th I

- Page 238 and 239:

The 12th I

- Page 240 and 241:

The 12th I

- Page 242 and 243:

In addition, it can also be observe

- Page 244 and 245:

The 12th I

- Page 246 and 247:

owner is normally only interested i

- Page 248 and 249:

The 12th I

- Page 250 and 251: The 12th I

- Page 252 and 253: The 12th I

- Page 254 and 255: The 12th I

- Page 256 and 257: The 12th I

- Page 258 and 259: The 12th I

- Page 260 and 261: The 12th I

- Page 262 and 263: The 12th I

- Page 264 and 265: The 12th I

- Page 266 and 267: The 12th I

- Page 268 and 269: The 12th I

- Page 270 and 271: The 12th I

- Page 272 and 273: The 12th I

- Page 274 and 275: The 12th I

- Page 276 and 277: The 12th I

- Page 278 and 279: The 12th I

- Page 280 and 281: The 12th I

- Page 282 and 283: The 12th I

- Page 284 and 285: The 12th I

- Page 286 and 287: The 12th I

- Page 288 and 289: The 12th I

- Page 290 and 291: Stockholm district heating system a

- Page 292 and 293: The 12th I

- Page 294 and 295: The 12th I

- Page 296 and 297: The 12th I

- Page 298 and 299: The 12th I

- Page 302 and 303: The 12th I

- Page 304 and 305: The 12th I

- Page 306 and 307: The 12th I

- Page 308 and 309: The 12th I

- Page 310 and 311: The 12th I

- Page 312 and 313: The 12th I

- Page 314 and 315: The values presented do of course l

- Page 316 and 317: The 12th I

- Page 318 and 319: The 12th I

- Page 320 and 321: The 12th I

- Page 322 and 323: The 12th I

- Page 324 and 325: The 12th I

- Page 326: The 12th I