TROLL 9500 Operator's Manual - Geotech Environmental Equipment

TROLL 9500 Operator's Manual - Geotech Environmental Equipment

TROLL 9500 Operator's Manual - Geotech Environmental Equipment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

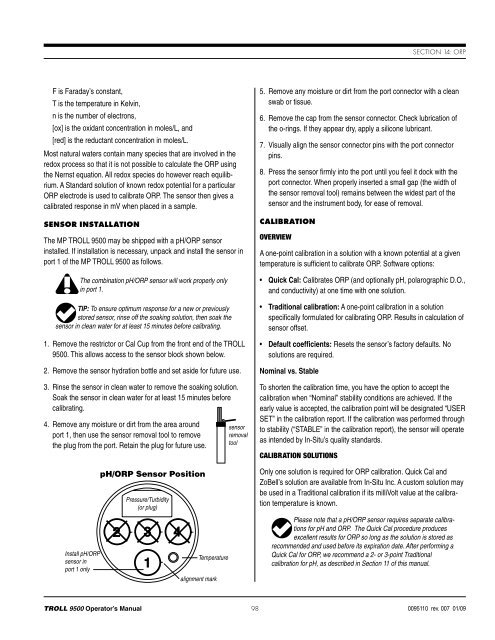

Section 14: orpF is Faraday’s constant,T is the temperature in Kelvin,n is the number of electrons,[ox] is the oxidant concentration in moles/L, and[red] is the reductant concentration in moles/L.Most natural waters contain many species that are involved in theredox process so that it is not possible to calculate the ORP usingthe Nernst equation. All redox species do however reach equilibrium.A Standard solution of known redox potential for a particularORP electrode is used to calibrate ORP. The sensor then gives acalibrated response in mV when placed in a sample.Sensor InstallationThe MP <strong>TROLL</strong> <strong>9500</strong> may be shipped with a pH/ORP sensorinstalled. If installation is necessary, unpack and install the sensor inport 1 of the MP <strong>TROLL</strong> <strong>9500</strong> as follows.The combination pH/ORP sensor will work properly onlyin port 1.TIP: To ensure optimum response for a new or previouslystored sensor, rinse off the soaking solution, then soak thesensor in clean water for at least 15 minutes before calibrating.1. Remove the restrictor or Cal Cup from the front end of the <strong>TROLL</strong><strong>9500</strong>. This allows access to the sensor block shown below.2. Remove the sensor hydration bottle and set aside for future use.3. Rinse the sensor in clean water to remove the soaking solution.Soak the sensor in clean water for at least 15 minutes beforecalibrating.4. Remove any moisture or dirt from the area aroundport 1, then use the sensor removal tool to removethe plug from the port. Retain the plug for future use.Install pH/ORPsensor inport 1 onlypH/ORP Sensor PositionPressure/Turbidity(or plug)Temperaturealignment marksensorremovaltool5. Remove any moisture or dirt from the port connector with a cleanswab or tissue.6. Remove the cap from the sensor connector. Check lubrication ofthe o-rings. If they appear dry, apply a silicone lubricant.7. Visually align the sensor connector pins with the port connectorpins.8. Press the sensor firmly into the port until you feel it dock with theport connector. When properly inserted a small gap (the width ofthe sensor removal tool) remains between the widest part of thesensor and the instrument body, for ease of removal.CalibrationOverviewA one-point calibration in a solution with a known potential at a giventemperature is sufficient to calibrate ORP. Software options:• Quick Cal: Calibrates ORP (and optionally pH, polarographic D.O.,and conductivity) at one time with one solution.• Traditional calibration: A one-point calibration in a solutionspecifically formulated for calibrating ORP. Results in calculation ofsensor offset.• Default coefficients: Resets the sensor’s factory defaults. Nosolutions are required.Nominal vs. StableTo shorten the calibration time, you have the option to accept thecalibration when “Nominal” stability conditions are achieved. If theearly value is accepted, the calibration point will be designated “USERSET” in the calibration report. If the calibration was performed throughto stability (“STABLE” in the calibration report), the sensor will operateas intended by In-Situ’s quality standards.Calibration SolutionsOnly one solution is required for ORP calibration. Quick Cal andZoBell’s solution are available from In-Situ Inc. A custom solution maybe used in a Traditional calibration if its milliVolt value at the calibrationtemperature is known.Please note that a pH/ORP sensor requires separate calibrationsfor pH and ORP. The Quick Cal procedure producesexcellent results for ORP so long as the solution is stored asrecommended and used before its expiration date. After performing aQuick Cal for ORP, we recommend a 2- or 3-point Traditionalcalibration for pH, as described in Section 11 of this manual.<strong>TROLL</strong> <strong>9500</strong> Operator’s <strong>Manual</strong> 980095110 rev. 007 01/09