TROLL 9500 Operator's Manual - Geotech Environmental Equipment

TROLL 9500 Operator's Manual - Geotech Environmental Equipment

TROLL 9500 Operator's Manual - Geotech Environmental Equipment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

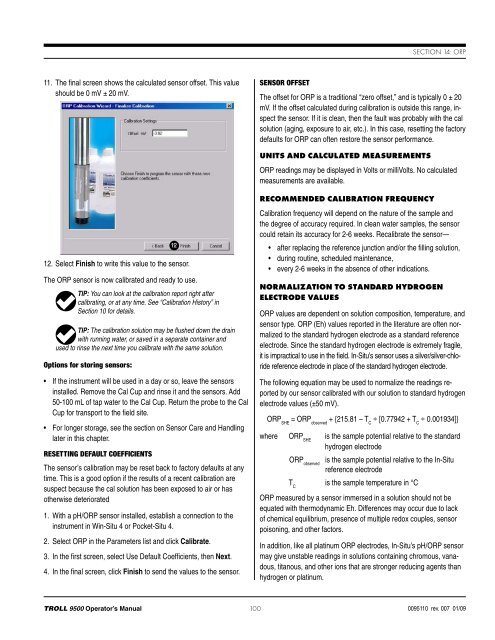

Section 14: orp11. The final screen shows the calculated sensor offset. This valueshould be 0 mV ± 20 mV.Sensor OffsetThe offset for ORP is a traditional “zero offset,” and is typically 0 ± 20mV. If the offset calculated during calibration is outside this range, inspectthe sensor. If it is clean, then the fault was probably with the calsolution (aging, exposure to air, etc.). In this case, resetting the factorydefaults for ORP can often restore the sensor performance.Units and Calculated MeasurementsORP readings may be displayed in Volts or milli Volts. No calculatedmeasurements are available.12. Select Finish to write this value to the sensor.The ORP sensor is now calibrated and ready to use.TIP: You can look at the calibration report right aftercalibrating, or at any time. See “Calibration History” inSection 10 for details.TIP: The calibration solution may be flushed down the drainwith running water, or saved in a separate container andused to rinse the next time you calibrate with the same solution.Options for storing sensors:• If the instrument will be used in a day or so, leave the sensorsinstalled. Remove the Cal Cup and rinse it and the sensors. Add50-100 mL of tap water to the Cal Cup. Return the probe to the CalCup for transport to the field site.• For longer storage, see the section on Sensor Care and Handlinglater in this chapter.Resetting Default CoefficientsThe sensor’s calibration may be reset back to factory defaults at anytime. This is a good option if the results of a recent calibration aresuspect because the cal solution has been exposed to air or hasotherwise deteriorated1. With a pH/ORP sensor installed, establish a connection to theinstrument in Win-Situ 4 or Pocket-Situ 4.2. Select ORP in the Parameters list and click Calibrate.3. In the first screen, select Use Default Coefficients, then Next.4. In the final screen, click Finish to send the values to the sensor.12Recommended Calibration FrequencyCalibration frequency will depend on the nature of the sample andthe degree of accuracy required. In clean water samples, the sensorcould retain its accuracy for 2-6 weeks. Recalibrate the sensor—• after replacing the reference junction and/or the filling solution,• during routine, scheduled maintenance,• every 2-6 weeks in the absence of other indications.Normalization to Standard HydrogenElectrode ValuesORP values are dependent on solution composition, temperature, andsensor type. ORP (Eh) values reported in the literature are often normalizedto the standard hydrogen electrode as a standard referenceelectrode. Since the standard hydrogen electrode is extremely fragile,it is impractical to use in the field. In-Situ’s sensor uses a silver/silver-chloridereference electrode in place of the standard hydrogen electrode.The following equation may be used to normalize the readings reportedby our sensor calibrated with our solution to standard hydrogenelectrode values (±50 mV).ORP SHE= ORP observed+ {215.81 – T C∗ [0.77942 + T C∗ 0.001934]}where ORP SHEis the sample potential relative to the standardhydrogen electrodeORP observedis the sample potential relative to the In-Situreference electrodeT Cis the sample temperature in °CORP measured by a sensor immersed in a solution should not beequated with thermodynamic Eh. Differences may occur due to lackof chemical equilibrium, presence of multiple redox couples, sensorpoisoning, and other factors.In addition, like all platinum ORP electrodes, In-Situ’s pH/ORP sensormay give unstable readings in solutions containing chromous, vanadous,titanous, and other ions that are stronger reducing agents thanhydrogen or platinum.<strong>TROLL</strong> <strong>9500</strong> Operator’s <strong>Manual</strong> 1000095110 rev. 007 01/09