TROLL 9500 Operator's Manual - Geotech Environmental Equipment

TROLL 9500 Operator's Manual - Geotech Environmental Equipment

TROLL 9500 Operator's Manual - Geotech Environmental Equipment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

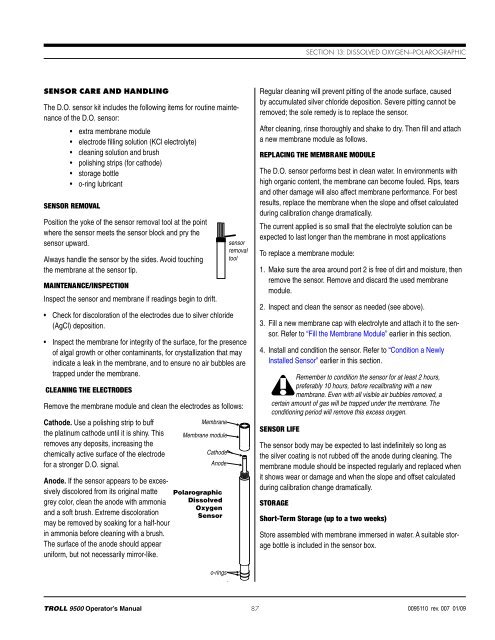

Section 13: Dissolved Oxygen—PolarographicSensor Care and HandlingThe D.O. sensor kit includes the following items for routine maintenanceof the D.O. sensor:• extra membrane module• electrode filling solution (KCl electrolyte)• cleaning solution and brush• polishing strips (for cathode)• storage bottle• o-ring lubricantSensor RemovalPosition the yoke of the sensor removal tool at the pointwhere the sensor meets the sensor block and pry thesensor upward.Always handle the sensor by the sides. Avoid touchingthe membrane at the sensor tip.Maintenance/InspectionInspect the sensor and membrane if readings begin to drift.• Check for discoloration of the elec trodes due to silver chloride(AgCl) deposition.• Inspect the membrane for integrity of the surface, for the presenceof algal growth or other contaminants, for crystallization that mayindicate a leak in the membrane, and to ensure no air bubbles aretrapped under the membrane.Cleaning the ElectrodesRemove the membrane module and clean the electrodes as follows:Cathode. Use a polishing strip to buffthe platinum cathode until it is shiny. Thisremoves any deposits, increasing thechemically active surface of the electrodefor a stronger D.O. signal.Anode. If the sensor appears to be excessivelydiscolored from its original mattegrey color, clean the anode with ammoniaand a soft brush. Extreme discolorationmay be removed by soaking for a half-hourin ammonia before cleaning with a brush.The surface of the anode should appearuniform, but not necessarily mirror-like.MembraneMembrane moduleCathodeAnodePolarographicDissolvedOxygenSensorsensorremovaltoolRegular cleaning will prevent pitting of the anode surface, causedby accumulated silver chloride deposition. Severe pitting cannot beremoved; the sole remedy is to replace the sensor.After cleaning, rinse thoroughly and shake to dry. Then fill and attacha new membrane module as follows.Replacing the Membrane ModuleThe D.O. sensor performs best in clean water. In environments withhigh organic content, the membrane can become fouled. Rips, tearsand other damage will also affect membrane performance. For bestresults, replace the membrane when the slope and offset calculatedduring calibration change dramatically.The current applied is so small that the electrolyte solution can beexpected to last longer than the membrane in most applicationsTo replace a membrane module:1. Make sure the area around port 2 is free of dirt and moisture, thenremove the sensor. Remove and discard the used membranemodule.2. Inspect and clean the sensor as needed (see above).3. Fill a new membrane cap with electrolyte and attach it to the sensor.Refer to “Fill the Membrane Module” earlier in this section.4. Install and condition the sensor. Refer to “Condition a NewlyInstalled Sensor” earlier in this section.Remember to condition the sensor for at least 2 hours,preferably 10 hours, before recalibrating with a newmembrane. Even with all visible air bubbles removed, acertain amount of gas will be trapped under the membrane. Theconditioning period will remove this excess oxygen.Sensor LifeThe sensor body may be expected to last indefinitely so long asthe silver coating is not rubbed off the anode during cleaning. Themembrane module should be inspected regularly and replaced whenit shows wear or damage and when the slope and offset calculatedduring calibration change dramatically.StorageShort-Term Storage (up to a two weeks)Store assembled with membrane immersed in water. A suitable storagebottle is included in the sensor box.o-rings<strong>TROLL</strong> <strong>9500</strong> Operator’s <strong>Manual</strong> 870095110 rev. 007 01/09