TROLL 9500 Operator's Manual - Geotech Environmental Equipment

TROLL 9500 Operator's Manual - Geotech Environmental Equipment

TROLL 9500 Operator's Manual - Geotech Environmental Equipment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

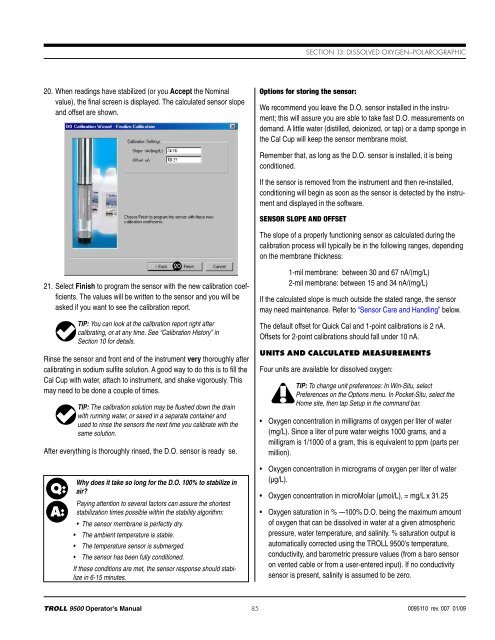

Section 13: Dissolved Oxygen—Polarographic20. When readings have stabilized (or you Accept the Nominalvalue), the final screen is displayed. The calculated sensor slopeand offset are shown.Options for storing the sensor:We recommend you leave the D.O. sensor installed in the instrument;this will assure you are able to take fast D.O. measurements ondemand. A little water (distilled, deionized, or tap) or a damp sponge inthe Cal Cup will keep the sensor membrane moist.Remember that, as long as the D.O. sensor is installed, it is beingconditioned.If the sensor is removed from the instrument and then re-installed,conditioning will begin as soon as the sensor is detected by the instrumentand displayed in the software.Sensor Slope and Offset21. Select Finish to program the sensor with the new calibration coefficients.The values will be written to the sensor and you will beasked if you want to see the calibration report.TIP: You can look at the calibration report right aftercalibrating, or at any time. See “Calibration History” inSection 10 for details.Rinse the sensor and front end of the instrument very thoroughly aftercalibrating in sodium sulfite solution. A good way to do this is to fill theCal Cup with water, attach to instrument, and shake vigorously. Thismay need to be done a couple of times.TIP: The calibration solution may be flushed down the drainwith running water, or saved in a separate container andused to rinse the sensors the next time you calibrate with thesame solution.After everything is thoroughly rinsed, the D.O. sensor is ready se.20The slope of a properly functioning sensor as calculated during thecalibration process will typically be in the following ranges, dependingon the membrane thickness:1-mil membrane: between 30 and 67 nA/(mg/L)2-mil membrane: between 15 and 34 nA/(mg/L)If the calculated slope is much outside the stated range, the sensormay need maintenance. Refer to “Sensor Care and Handling” below.The default offset for Quick Cal and 1-point calibrations is 2 nA.Offsets for 2-point calibrations should fall under 10 nA.Units and Calculated MeasurementsFour units are available for dissolved oxygen:TIP: To change unit preferences: In Win-Situ, selectPreferences on the Options menu. In Pocket-Situ, select theHome site, then tap Setup in the command bar.• Oxygen concentration in milligrams of oxygen per liter of water(mg/L). Since a liter of pure water weighs 1000 grams, and amilligram is 1/1000 of a gram, this is equivalent to ppm (parts permillion).Q:A:Why does it take so long for the D.O. 100% to stabilize inair?Paying attention to several factors can assure the shorteststabilization times possible within the stability algorithm:• The sensor membrane is perfectly dry.• The ambient temperature is stable.• The temperature sensor is submerged.• The sensor has been fully conditioned.If these conditions are met, the sensor response should stabilizein 6-15 minutes.• Oxygen concentration in micrograms of oxygen per liter of water(µg/L).• Oxygen concentration in microMolar (µmol/L), = mg/L x 31.25• Oxygen saturation in % —100% D.O. being the maximum amountof oxygen that can be dissolved in water at a given atmosphericpressure, water temperature, and salinity. % saturation output isautomatically corrected using the <strong>TROLL</strong> <strong>9500</strong>’s temperature,conductivity, and barometric pressure values (from a baro sensoron vented cable or from a user-entered input). If no conductivitysensor is present, salinity is assumed to be zero.<strong>TROLL</strong> <strong>9500</strong> Operator’s <strong>Manual</strong> 850095110 rev. 007 01/09