TROLL 9500 Operator's Manual - Geotech Environmental Equipment

TROLL 9500 Operator's Manual - Geotech Environmental Equipment

TROLL 9500 Operator's Manual - Geotech Environmental Equipment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

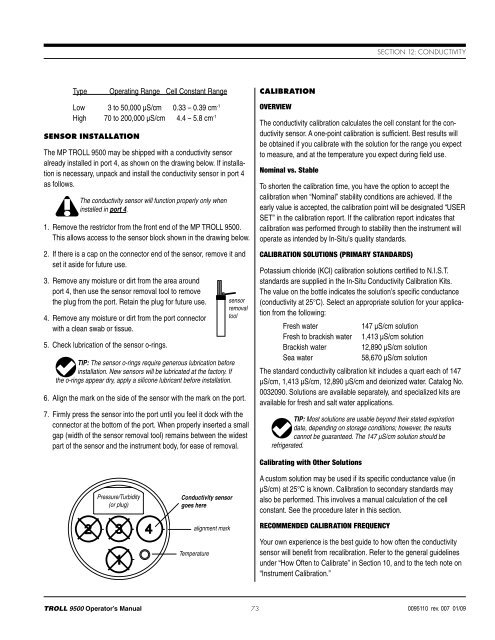

Section 12: ConductivityTypeOperating Range Cell Constant RangeLow 3 to 50,000 µS/cm 0.33 – 0.39 cm -1High 70 to 200,000 µS/cm 4.4 – 5.8 cm -1Sensor InstallationThe MP <strong>TROLL</strong> <strong>9500</strong> may be shipped with a conductivity sensoralready installed in port 4, as shown on the drawing below. If installationis necessary, unpack and install the conductivity sensor in port 4as follows.The conductivity sensor will function properly only wheninstalled in port 4.1. Remove the restrictor from the front end of the MP <strong>TROLL</strong> <strong>9500</strong>.This allows access to the sensor block shown in the drawing below.2. If there is a cap on the connector end of the sensor, remove it andset it aside for future use.3. Remove any moisture or dirt from the area aroundport 4, then use the sensor removal tool to removethe plug from the port. Retain the plug for future use.4. Remove any moisture or dirt from the port connectorwith a clean swab or tissue.5. Check lubrication of the sensor o-rings.TIP: The sensor o-rings require generous lubrication beforeinstallation. New sensors will be lubricated at the factory. Ifthe o-rings appear dry, apply a silicone lubricant before installation.sensorremovaltool6. Align the mark on the side of the sensor with the mark on the port.7. Firmly press the sensor into the port until you feel it dock with theconnector at the bottom of the port. When properly inserted a smallgap (width of the sensor removal tool) remains between the widestpart of the sensor and the instrument body, for ease of removal.CalibrationOverviewThe conductivity calibration calculates the cell constant for the conductivitysensor. A one-point calibration is sufficient. Best results willbe obtained if you calibrate with the solution for the range you expectto measure, and at the temperature you expect during field use.Nominal vs. StableTo shorten the calibration time, you have the option to accept thecalibration when “Nominal” stability conditions are achieved. If theearly value is accepted, the calibration point will be designated “USERSET” in the calibration report. If the calibration report indicates thatcalibration was performed through to stability then the instrument willoperate as intended by In-Situ’s quality standards.Calibration Solutions (Primary Standards)Potassium chloride (KCl) calibration solutions certified to N.I.S.T.standards are supplied in the In-Situ Conductivity Calibration Kits.The value on the bottle indicates the solution’s specific conductance(conductivity at 25°C). Select an appropriate solution for your applicationfrom the following:Fresh water147 µS/cm solutionFresh to brackish water 1,413 µS/cm solutionBrackish water 12,890 µS/cm solutionSea water58,670 µS/cm solutionThe standard conductivity calibration kit includes a quart each of 147µS/cm, 1,413 µS/cm, 12,890 µS/cm and deionized water. Catalog No.0032090. Solutions are available separately, and specialized kits areavailable for fresh and salt water applications.TIP: Most solutions are usable beyond their stated expirationdate, depending on storage conditions; however, the resultscannot be guaranteed. The 147 µS/cm solution should berefrigerated.Pressure/Turbidity(or plug)Conductivity sensorgoes herealignment markTemperatureCalibrating with Other SolutionsA custom solution may be used if its specific conductance value (inµS/cm) at 25°C is known. Calibration to secondary standards mayalso be performed. This involves a manual calculation of the cellconstant. See the procedure later in this section.Recommended Calibration FrequencyYour own experience is the best guide to how often the conductivitysensor will benefit from recalibration. Refer to the general guidelinesunder “How Often to Calibrate” in Section 10, and to the tech note on“Instrument Calibration.”<strong>TROLL</strong> <strong>9500</strong> Operator’s <strong>Manual</strong> 730095110 rev. 007 01/09