- Seite 1 und 2:

Tank + Chemie-Schläuche1Petrol + C

- Seite 3 und 4:

GRUPPE GE-WICHT1 WeightApprox.SCHLA

- Seite 5 und 6:

TECHNISCHE ÄNDERUNGEN VORBEHALTEN

- Seite 7 und 8:

'ltX' -leicht-tankwagenschlauchfür

- Seite 9 und 10:

GRUPPE GE-WICHT1 WeightApprox.SCHLA

- Seite 11 und 12:

TECHNISCHE ÄNDERUNGEN VORBEHALTEN

- Seite 13 und 14:

GRUPPE GE-WICHT1 WeightApprox.SCHLA

- Seite 15 und 16:

GRUPPE GE-WICHT1 WeightApprox.SCHLA

- Seite 17 und 18:

GRUPPE GE-WICHT1 WeightApprox.SCHLA

- Seite 19 und 20:

GRUPPE GE-WICHT1 WeightApprox.SCHLA

- Seite 21 und 22:

GRUPPE GE-WICHT1 WeightApprox.SCHLA

- Seite 23 und 24:

GRUPPE1SectionGe- SCHLAUCH- BESTELL

- Seite 25 und 26:

ELAPHARM ®Schlauchleitungen für d

- Seite 27 und 28:

Gruppe Gewicht1 WeightApprox.Schlau

- Seite 29 und 30:

GRUPPE GE-WICHT1 WeightApprox.SCHLA

- Seite 31 und 32:

GRUPPE1SectionGE- SCHLAUCH- BESTELL

- Seite 33 und 34:

' FLUORFLEX 2 'PTFE / EPDM Universa

- Seite 35 und 36:

Gruppe GewichtWeight1Approx.Schlauc

- Seite 37 und 38:

GRUPPE GE-WICHT1 WeightApprox.SCHLA

- Seite 39 und 40:

GRUPPE GE-WICHT1 WeightApprox.SCHLA

- Seite 41 und 42:

GRUPPE1 WeightApprox.GE- SCHLAUCH-W

- Seite 43:

Gaspendelschlauch GPSVapour recover

- Seite 46 und 47:

PAL-- Markenschläuche:BESSER ALS D

- Seite 48 und 49:

CHEMOPAL ® TECNOPAL ®Chemieschlau

- Seite 50 und 51:

Die komplette Schlauchleitungvom PA

- Seite 52 und 53:

European Pressure Equipment Directi

- Seite 54 und 55:

Zeichenerklärung| AB. 123 | meistg

- Seite 56 und 57:

Sonderausführungen + Zubehör . Sp

- Seite 58 und 59:

Montage von Schraubhülsen-Einbindu

- Seite 60 und 61:

Bedruckung von SortentüllenELAFLEX

- Seite 62 und 63:

Montage von SPANNFIX-EinbindungenDi

- Seite 64 und 65:

Sonderausführungen · Special Type

- Seite 66 und 67:

Sonderausführungen · Special Type

- Seite 68 und 69:

Montage von SPANNLOC-Klemmbacken ·

- Seite 70 und 71:

Vakuum-Umrechnungstabelle · Differ

- Seite 72 und 73:

Gebräuchliche Gewindemaße · Comm

- Seite 74 und 75:

450400F 0 C 0 30C 0 bar bar psi2402

- Seite 76 und 77:

Zubehör + Ersatzteile · Accessori

- Seite 78 und 79:

Montagewerkzeug . Assembling Tools1

- Seite 80 und 81:

Beständigkeitsübersicht Armaturen

- Seite 82 und 83:

Sonderausführungen · Special Type

- Seite 84 und 85:

Sonderausführungen . Special Types

- Seite 86 und 87:

Sonderausführungen + Montagewerkze

- Seite 88 und 89:

Montage von SPANNLOC-Klemmbacken .

- Seite 90 und 91:

Sonderausführungen· Special Types

- Seite 92 und 93:

Gebräuchliche Maße für Schlauchf

- Seite 94 und 95:

Sonderausführungen · Special Type

- Seite 97 und 98:

GRUPPE2GE- SCHLAUCH- FLANSCH- FLANS

- Seite 99 und 100:

TECHNISCHE ÄnderunGen VorBehalten

- Seite 101 und 102:

GRUPPEGE-WICHT2 WeightApprox.max.\m

- Seite 103:

Mögliche Längen für ELAFLEX-Schl

- Seite 106 und 107:

Zeichenerklärung| AB. 123 | meistg

- Seite 108 und 109:

Sonderausführung · Special TypesD

- Seite 110 und 111:

DlDie Schemazeichnung zeigt eine EL

- Seite 112 und 113:

Kupplungsdichtungen 'KD' für TW-Ku

- Seite 114 und 115:

TW Couplings with active Safeguard

- Seite 116 und 117:

Problemfälle bei der Kombination v

- Seite 119 und 120:

GRUPPE Ge· ABMESSUNGEN WERKSTOFFE

- Seite 121 und 122:

GRUPPE3 WeightApprox.dAUSFÜHRUNGWE

- Seite 123 und 124:

GRUPPEGE-WICHTAUSFÜHRUNGWERKSTOFFE

- Seite 125 und 126:

GruppeGewicht3 WeightApprox.Grösse

- Seite 127 und 128:

GruppeGewicht3 WeightApprox.Grösse

- Seite 129 und 130:

GRUPPEGE-WICHT3 WeightApprox.WERKST

- Seite 131 und 132:

GRUPPEGE-WICHT3 WeightApprox.ABMESS

- Seite 133 und 134:

GRUPPEGE-WICHT3 WeightApprox.DNGRÖ

- Seite 135 und 136:

TECHNISCHE ÄNDERUNGEN VORBEHALTEN

- Seite 137 und 138:

TECHNISCHE ÄNDERUNGEN VORBEHALTEN

- Seite 139 und 140:

TECHNISCHE ÄNDERUNGEN VORBEHALTEN

- Seite 141 und 142:

TECHNISCHE ÄNDERUNGEN VORBEHALTEN

- Seite 143 und 144:

GRUPPEGewicht3 WeightApprox.GRÖSSE

- Seite 145 und 146:

GRUPPE3WeightApprox.GE- ABMESSUNGEN

- Seite 147 und 148:

GRUPPE3WeightApprox.GE- ABMESSUNGEN

- Seite 149 und 150:

TECHNISCHE ÄNDERUNGEN VORBEHALTEN

- Seite 151 und 152:

GRUPPE3SectionGE- ABMESSUNGEN FORM

- Seite 153 und 154:

GRUPPE3GE- ABMESSUNGEN FORM WERKSTO

- Seite 155 und 156:

TECHNISCHE ÄNDERUNGEN VORBEHALTEN

- Seite 157 und 158:

GRUPPE3 WeightApprox.GE- WERKSTOFFE

- Seite 159 und 160:

GRUPPE3 WeightApprox.GewichtWERKSTO

- Seite 161 und 162:

GRUPPE3 WeightApprox.GewichtWERKSTO

- Seite 163 und 164:

TECHNISCHE ÄNDERUNGEN VORBEHALTEN

- Seite 165 und 166: TECHNIsche ÄnderunGen Vorbehalten

- Seite 167 und 168: TECHNISCHE ÄNDERUNGEN VORBEHALTEN

- Seite 169 und 170: GRUPPE3SectionGe- VERWENDUNG FÜR A

- Seite 171 und 172: GRUPPE3GE- GRÖSSE WERKSTOFFE1)ABME

- Seite 173 und 174: TECHNISCHE ÄNDERUNGEN VORBEHALTEN

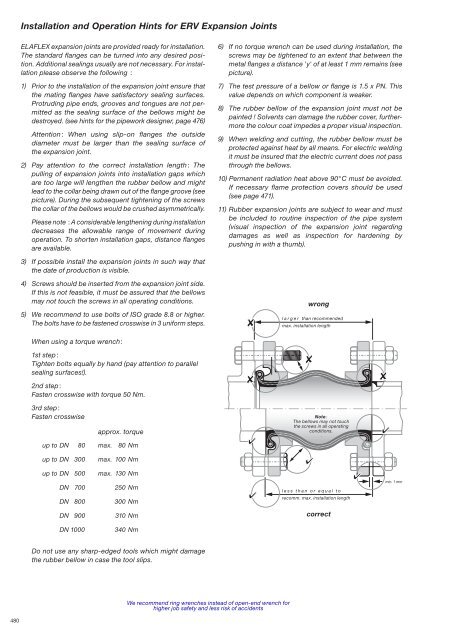

- Seite 175 und 176: Gummi- KompensatorenRubber Expansio

- Seite 177 und 178: GRUPPE4SectionType Innen / Liner Ha

- Seite 179 und 180: SSVSDFlansch Material 3)Flange Mate

- Seite 181 und 182: TECHNISCHE ÄNDERUNGEN VORBEHALTEN

- Seite 183 und 184: TECHNISCHE ÄNDERUNGEN VORBEHALTEN

- Seite 185 und 186: TECHNISCHE ÄNDERUNGEN VORBEHALTEN

- Seite 187 und 188: GRUPPE GEWICHTWirks.fläche4 Weig

- Seite 189 und 190: TECHNISCHE ÄNDERUNGEN VORBEHALTEN

- Seite 191 und 192: GRUPPE4SectionGe- Wirks. BALG PN FL

- Seite 193 und 194: GruppeWirks.Fläche4 Weight Effect.

- Seite 195 und 196: GRUPPE GE- WIRKS.WICHT FLÄCHE4 Wei

- Seite 197 und 198: GruppeWirks.Fläche4 Weight Effect.

- Seite 199 und 200: Gruppe GewichtWirks.fläche4 Weight

- Seite 201 und 202: GRUPPE GE- WIRKS.WICHT FLÄCHE4 Wei

- Seite 203 und 204: GRUPPEGE- Wirks.WICHT Fläche4 Weig

- Seite 205 und 206: GRUPPE4SectionTECHNISCHE ÄNDERUNGE

- Seite 207 und 208: FlanschnormFlange StandardBestellnu

- Seite 209 und 210: TECHNISCHE ÄNDERUNGEN VORBEHALTEN

- Seite 211 und 212: Gruppe DN I D Länge L BesteLLnumme

- Seite 213 und 214: GRUPPE4SectionTECHNISCHE ÄNDERUNGE

- Seite 215: GRUPPE4SectionELAFLEX-Gummikompensa

- Seite 219 und 220: Zapfventile+ Zubehör5Fuel Dispensi

- Seite 221 und 222: TECHNISCHE ÄNDERUNGEN VORBEHALTEN

- Seite 223 und 224: GRUPPE GE-WICHTWeight5ApproxSCHLAUC

- Seite 225: GRUPPEGE-WICHT5WeightApproxAUSFÜHR

- Seite 228 und 229: 59677583919910711512360687684921001

- Seite 230 und 231: 25125926727528329129930731525226026

- Seite 232 und 233: 44344444544744844945045145245445545

- Seite 234 und 235: Ersatzteile, Werkzeuge ZVA Slimline

- Seite 236 und 237: LeistungskurveZVA Slimline 2 GR----

- Seite 238 und 239: GE-WICHTWird gebraucht fürZapfsäu

- Seite 240 und 241: GErsatzteile, Werkzeuge ZVA Slimlin

- Seite 242 und 243: Leistungsvergleich1,8von ELAFLEX-Au

- Seite 244 und 245: Beständigkeitsübersicht für ZVA

- Seite 246 und 247: ELAFLEX REUSABLE PUMP BREAKFIELD RE

- Seite 248 und 249: AdBlueErsatzteile ZVA Slimline AdBl

- Seite 250 und 251: GRUPPE3GE- ABMESSUNGEN FORM WERKSTO

- Seite 252 und 253: Leistungsvergleichvon ELAFLEX Autom

- Seite 254 und 255: Automatic nozzle ZVA 25 GR :Active

- Seite 256 und 257: ZVA 32Kugel-Kipp-Ventilsafety cut o

- Seite 258 und 259: Druckverlustmit Schaugläsern----Pr

- Seite 260 und 261: Beständigkeitsübersicht für ZV +

- Seite 262 und 263: Leistungsvergleich0,8von ELAFLEX-Za

- Seite 264 und 265: Leistungsvergleichvon ELAFLEX-Zapfv

- Seite 266 und 267:

Sonderausführung · Special Type"R

- Seite 268 und 269:

Sonderausführungen · Special Type

- Seite 270 und 271:

Leistungsvergleichvon ELAFLEX-Zapfv

- Seite 272 und 273:

Ersatzteile ZVG 2 · Spare Parts ZV

- Seite 274 und 275:

Druckverlustkurvenfür Flüssiggas-

- Seite 276:

Druckverlustkurvenfür GasGuardFlü

- Seite 279 und 280:

Unsere Historie1923 Gründung durch

- Seite 281 und 282:

Unser ProfilHauptsitz:HamburgMitarb

- Seite 283 und 284:

Marktführer in den BereichenTankst

- Seite 285 und 286:

LPG-Betankung:- Schläuche- Zapfven

- Seite 287 und 288:

Chemische Industrie- Schlauchleitun

- Seite 289 und 290:

Gummi-Kompensatoren(Type ERV)für A

- Seite 291 und 292:

ELAFLEX HIBY,Plettenberg(Herstellun

- Seite 293 und 294:

VertriebsbereicheEHTELAFLEX HIBY Ta

- Seite 295 und 296:

200 autorisierteVertriebspartnerwel

- Seite 297 und 298:

Tank + ChemieschläucheNormgerechte

- Seite 299 und 300:

Normgerecht - Sicher - Langlebig.Ta

- Seite 301:

ZVA Slimline 2 (EN 13012, TRbF 513,