ASA JOURNAL 14/2023

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

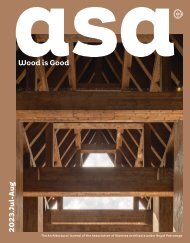

MATERIALS, TOOLS, TECHNIQUES FUNDAMENTAL FACTORS<br />

IN THE DESIGN PROCESS AND WOOD ARCHITECTURAL WORK<br />

135<br />

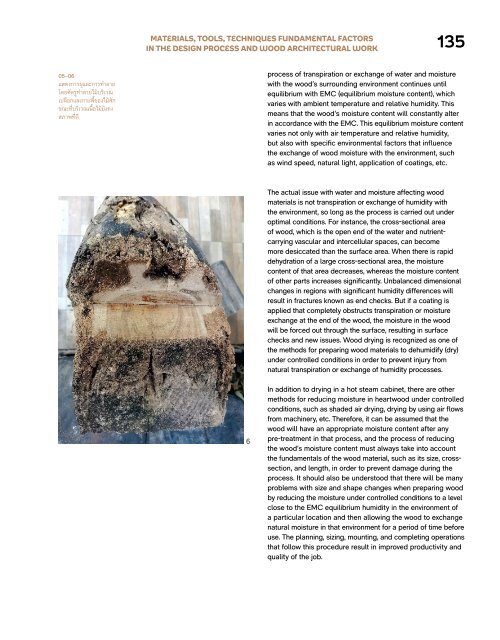

05-06<br />

แสดงการผุและการทำาลาย<br />

โดยศัตรูทำาลายไม้บริเวณ<br />

เปลือกและกระพี้ของไม้สัก<br />

ขณะที่บริเวณเนื้อไม้ยังคง<br />

สภาพที่ดี<br />

process of transpiration or exchange of water and moisture<br />

with the wood’s surrounding environment continues until<br />

equilibrium with EMC (equilibrium moisture content), which<br />

varies with ambient temperature and relative humidity. This<br />

means that the wood’s moisture content will constantly alter<br />

in accordance with the EMC. This equilibrium moisture content<br />

varies not only with air temperature and relative humidity,<br />

but also with specific environmental factors that influence<br />

the exchange of wood moisture with the environment, such<br />

as wind speed, natural light, application of coatings, etc.<br />

The actual issue with water and moisture affecting wood<br />

materials is not transpiration or exchange of humidity with<br />

the environment, so long as the process is carried out under<br />

optimal conditions. For instance, the cross-sectional area<br />

of wood, which is the open end of the water and nutrientcarrying<br />

vascular and intercellular spaces, can become<br />

more desiccated than the surface area. When there is rapid<br />

dehydration of a large cross-sectional area, the moisture<br />

content of that area decreases, whereas the moisture content<br />

of other parts increases significantly. Unbalanced dimensional<br />

changes in regions with significant humidity differences will<br />

result in fractures known as end checks. But if a coating is<br />

applied that completely obstructs transpiration or moisture<br />

exchange at the end of the wood, the moisture in the wood<br />

will be forced out through the surface, resulting in surface<br />

checks and new issues. Wood drying is recognized as one of<br />

the methods for preparing wood materials to dehumidify (dry)<br />

under controlled conditions in order to prevent injury from<br />

natural transpiration or exchange of humidity processes.<br />

6<br />

In addition to drying in a hot steam cabinet, there are other<br />

methods for reducing moisture in heartwood under controlled<br />

conditions, such as shaded air drying, drying by using air flows<br />

from machinery, etc. Therefore, it can be assumed that the<br />

wood will have an appropriate moisture content after any<br />

pre-treatment in that process, and the process of reducing<br />

the wood’s moisture content must always take into account<br />

the fundamentals of the wood material, such as its size, crosssection,<br />

and length, in order to prevent damage during the<br />

process. It should also be understood that there will be many<br />

problems with size and shape changes when preparing wood<br />

by reducing the moisture under controlled conditions to a level<br />

close to the EMC equilibrium humidity in the environment of<br />

a particular location and then allowing the wood to exchange<br />

natural moisture in that environment for a period of time before<br />

use. The planning, sizing, mounting, and completing operations<br />

that follow this procedure result in improved productivity and<br />

quality of the job.