Textos de Apoio (pdf)

Textos de Apoio (pdf)

Textos de Apoio (pdf)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ITTC – Recommen<strong>de</strong>d<br />

7.5-04<br />

-01-01.1<br />

Procedures and Gui<strong>de</strong>lines Page 5 of 10<br />

Full Scale Measurements<br />

Speed and Power Trials<br />

Preparation and Conduct of<br />

Speed/Power Trials<br />

Effective Date<br />

2005<br />

Revision<br />

03<br />

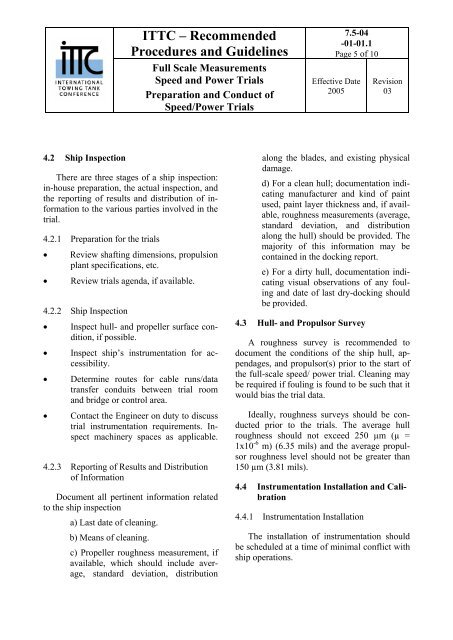

4.2 Ship Inspection<br />

There are three stages of a ship inspection:<br />

in-house preparation, the actual inspection, and<br />

the reporting of results and distribution of information<br />

to the various parties involved in the<br />

trial.<br />

4.2.1 Preparation for the trials<br />

• Review shafting dimensions, propulsion<br />

plant specifications, etc.<br />

• Review trials agenda, if available.<br />

4.2.2 Ship Inspection<br />

• Inspect hull- and propeller surface condition,<br />

if possible.<br />

• Inspect ship’s instrumentation for accessibility.<br />

• Determine routes for cable runs/data<br />

transfer conduits between trial room<br />

and bridge or control area.<br />

• Contact the Engineer on duty to discuss<br />

trial instrumentation requirements. Inspect<br />

machinery spaces as applicable.<br />

4.2.3 Reporting of Results and Distribution<br />

of Information<br />

Document all pertinent information related<br />

to the ship inspection<br />

a) Last date of cleaning.<br />

b) Means of cleaning.<br />

c) Propeller roughness measurement, if<br />

available, which should inclu<strong>de</strong> average,<br />

standard <strong>de</strong>viation, distribution<br />

along the bla<strong>de</strong>s, and existing physical<br />

damage.<br />

d) For a clean hull; documentation indicating<br />

manufacturer and kind of paint<br />

used, paint layer thickness and, if available,<br />

roughness measurements (average,<br />

standard <strong>de</strong>viation, and distribution<br />

along the hull) should be provi<strong>de</strong>d. The<br />

majority of this information may be<br />

contained in the docking report.<br />

e) For a dirty hull, documentation indicating<br />

visual observations of any fouling<br />

and date of last dry-docking should<br />

be provi<strong>de</strong>d.<br />

4.3 Hull- and Propulsor Survey<br />

A roughness survey is recommen<strong>de</strong>d to<br />

document the conditions of the ship hull, appendages,<br />

and propulsor(s) prior to the start of<br />

the full-scale speed/ power trial. Cleaning may<br />

be required if fouling is found to be such that it<br />

would bias the trial data.<br />

I<strong>de</strong>ally, roughness surveys should be conducted<br />

prior to the trials. The average hull<br />

roughness should not exceed 250 µm (µ =<br />

1x10 -6 m) (6.35 mils) and the average propulsor<br />

roughness level should not be greater than<br />

150 µm (3.81 mils).<br />

4.4 Instrumentation Installation and Calibration<br />

4.4.1 Instrumentation Installation<br />

The installation of instrumentation should<br />

be scheduled at a time of minimal conflict with<br />

ship operations.

![Conceitos transmissao de dados .Sinais[.pdf]](https://img.yumpu.com/50982145/1/190x146/conceitos-transmissao-de-dados-sinaispdf.jpg?quality=85)

![Packages e interfaces[.pdf]](https://img.yumpu.com/50629553/1/190x134/packages-e-interfacespdf.jpg?quality=85)