Textos de Apoio (pdf)

Textos de Apoio (pdf)

Textos de Apoio (pdf)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

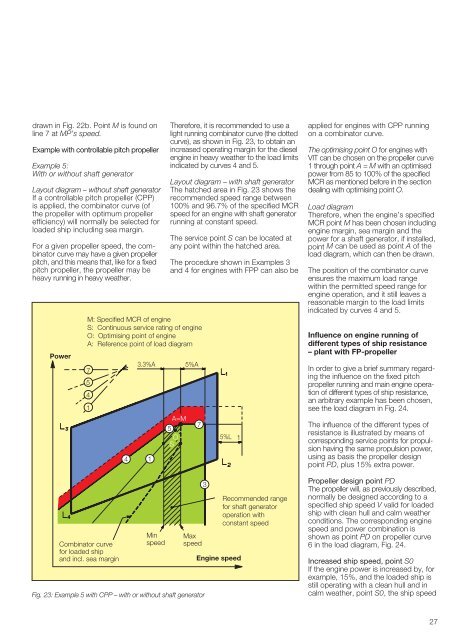

drawn in Fig. 22b. Point M is found on<br />

line 7 at MP’s speed.<br />

Example with controllable pitch propeller<br />

Example 5:<br />

With or without shaft generator<br />

Layout diagram – without shaft generator<br />

If a controllable pitch propeller (CPP)<br />

is applied, the combinator curve (of<br />

the propeller with optimum propeller<br />

efficiency) will normally be selected for<br />

loa<strong>de</strong>d ship including sea margin.<br />

For a given propeller speed, the combinator<br />

curve may have a given propeller<br />

pitch, and this means that, like for a fixed<br />

pitch propeller, the propeller may be<br />

heavy running in heavy weather.<br />

Power<br />

M: Specified MCR of engine<br />

S: Continuous service rating of engine<br />

O: Optimising point of engine<br />

A: Reference point of load diagram<br />

7<br />

5<br />

4<br />

1<br />

Combinator curve<br />

for loa<strong>de</strong>d ship<br />

and incl. sea margin<br />

3.3%A<br />

1<br />

Min<br />

speed<br />

Therefore, it is recommen<strong>de</strong>d to use a<br />

light running combinator curve (the dotted<br />

curve), as shown in Fig. 23, to obtain an<br />

increased operating margin for the diesel<br />

engine in heavy weather to the load limits<br />

indicated by curves 4 and 5.<br />

Layout diagram – with shaft generator<br />

The hatched area in Fig. 23 shows the<br />

recommen<strong>de</strong>d speed range between<br />

100% and 96.7% of the specified MCR<br />

speed for an engine with shaft generator<br />

running at constant speed.<br />

The service point S can be located at<br />

any point within the hatched area.<br />

The procedure shown in Examples 3<br />

and 4 for engines with FPP can also be<br />

A=M<br />

5<br />

O<br />

S<br />

5%A<br />

7<br />

Max<br />

speed<br />

Fig. 23: Example 5 with CPP – with or without shaft generator<br />

4<br />

3<br />

5%L<br />

1<br />

Engine speed<br />

Recommen<strong>de</strong>d range<br />

for shaft generator<br />

operation with<br />

constant speed<br />

applied for engines with CPP running<br />

on a combinator curve.<br />

The optimising point O for engines with<br />

VIT can be chosen on the propeller curve<br />

1 through point A=Mwith an optimised<br />

power from 85 to 100% of the specified<br />

MCR as mentioned before in the section<br />

<strong>de</strong>aling with optimising point O.<br />

Load diagram<br />

Therefore, when the engine’s specified<br />

MCR point M has been chosen including<br />

engine margin, sea margin and the<br />

power for a shaft generator, if installed,<br />

point M can be used as point A of the<br />

load diagram, which can then be drawn.<br />

The position of the combinator curve<br />

ensures the maximum load range<br />

within the permitted speed range for<br />

engine operation, and it still leaves a<br />

reasonable margin to the load limits<br />

indicated by curves 4 and 5.<br />

Influence on engine running of<br />

different types of ship resistance<br />

– plant with FP-propeller<br />

In or<strong>de</strong>r to give a brief summary regarding<br />

the influence on the fixed pitch<br />

propeller running and main engine operation<br />

of different types of ship resistance,<br />

an arbitrary example has been chosen,<br />

see the load diagram in Fig. 24.<br />

The influence of the different types of<br />

resistance is illustrated by means of<br />

corresponding service points for propulsion<br />

having the same propulsion power,<br />

using as basis the propeller <strong>de</strong>sign<br />

point PD, plus 15% extra power.<br />

Propeller <strong>de</strong>sign point PD<br />

The propeller will, as previously <strong>de</strong>scribed,<br />

normally be <strong>de</strong>signed according to a<br />

specified ship speed V valid for loa<strong>de</strong>d<br />

ship with clean hull and calm weather<br />

conditions. The corresponding engine<br />

speed and power combination is<br />

shown as point PD on propeller curve<br />

6 in the load diagram, Fig. 24.<br />

Increased ship speed, point S0<br />

If the engine power is increased by, for<br />

example, 15%, and the loa<strong>de</strong>d ship is<br />

still operating with a clean hull and in<br />

calm weather, point S0, the ship speed<br />

27

![Conceitos transmissao de dados .Sinais[.pdf]](https://img.yumpu.com/50982145/1/190x146/conceitos-transmissao-de-dados-sinaispdf.jpg?quality=85)

![Packages e interfaces[.pdf]](https://img.yumpu.com/50629553/1/190x134/packages-e-interfacespdf.jpg?quality=85)