Textos de Apoio (pdf)

Textos de Apoio (pdf)

Textos de Apoio (pdf)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Case 4: Derating without adding an<br />

engine cylin<strong>de</strong>r<br />

It is also feasible to apply a <strong>de</strong>rated engine to obtain<br />

fuel savings in such a way that an additional engine<br />

cylin<strong>de</strong>r is not required.<br />

An example of this can be seen with the Wärtsilä<br />

RT-flex50 engine. In October 2007, the D version<br />

of this engine was announced, in which the engine<br />

power was increased by 5.1 per cent and the BSFC<br />

at full-load was reduced by 2 g/kWh compared with<br />

the B version.<br />

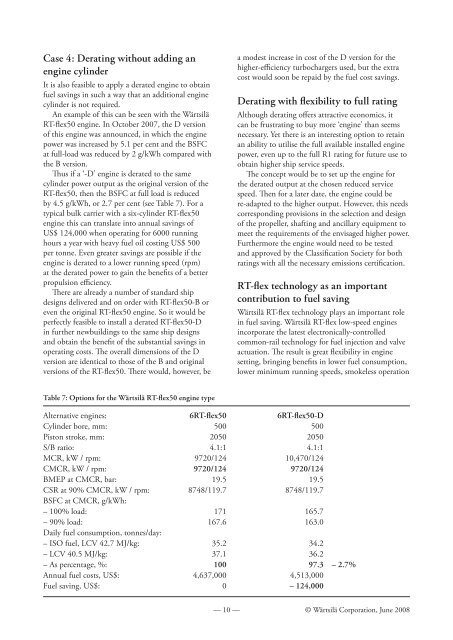

Thus if a ‘-D’ engine is <strong>de</strong>rated to the same<br />

cylin<strong>de</strong>r power output as the original version of the<br />

RT-flex50, then the BSFC at full load is reduced<br />

by 4.5 g/kWh, or 2.7 per cent (see Table 7). For a<br />

typical bulk carrier with a six-cylin<strong>de</strong>r RT-flex50<br />

engine this can translate into annual savings of<br />

US$ 124,000 when operating for 6000 running<br />

hours a year with heavy fuel oil costing US$ 500<br />

per tonne. Even greater savings are possible if the<br />

engine is <strong>de</strong>rated to a lower running speed (rpm)<br />

at the <strong>de</strong>rated power to gain the benefits of a better<br />

propulsion efficiency.<br />

There are already a number of standard ship<br />

<strong>de</strong>signs <strong>de</strong>livered and on or<strong>de</strong>r with RT-flex50-B or<br />

even the original RT-flex50 engine. So it would be<br />

perfectly feasible to install a <strong>de</strong>rated RT-flex50-D<br />

in further newbuildings to the same ship <strong>de</strong>signs<br />

and obtain the benefit of the substantial savings in<br />

operating costs. The overall dimensions of the D<br />

version are i<strong>de</strong>ntical to those of the B and original<br />

versions of the RT-flex50. There would, however, be<br />

a mo<strong>de</strong>st increase in cost of the D version for the<br />

higher-efficiency turbochargers used, but the extra<br />

cost would soon be repaid by the fuel cost savings.<br />

Derating with flexibility to full rating<br />

Although <strong>de</strong>rating offers attractive economics, it<br />

can be frustrating to buy more ‘engine’ than seems<br />

necessary. Yet there is an interesting option to retain<br />

an ability to utilise the full available installed engine<br />

power, even up to the full R1 rating for future use to<br />

obtain higher ship service speeds.<br />

The concept would be to set up the engine for<br />

the <strong>de</strong>rated output at the chosen reduced service<br />

speed. Then for a later date, the engine could be<br />

re-adapted to the higher output. However, this needs<br />

corresponding provisions in the selection and <strong>de</strong>sign<br />

of the propeller, shafting and ancillary equipment to<br />

meet the requirements of the envisaged higher power.<br />

Furthermore the engine would need to be tested<br />

and approved by the Classification Society for both<br />

ratings with all the necessary emissions certification.<br />

RT-flex technology as an important<br />

contribution to fuel saving<br />

Wärtsilä RT-flex technology plays an important role<br />

in fuel saving. Wärtsilä RT-flex low-speed engines<br />

incorporate the latest electronically-controlled<br />

common-rail technology for fuel injection and valve<br />

actuation. The result is great flexibility in engine<br />

setting, bringing benefits in lower fuel consumption,<br />

lower minimum running speeds, smokeless operation<br />

Table 7: Options for the Wärtsilä RT-flex50 engine type<br />

Alternative engines: 6RT-flex50 6RT-flex50-D<br />

Cylin<strong>de</strong>r bore, mm: 500 500<br />

Piston stroke, mm: 2050 2050<br />

S/B ratio: 4.1:1 4.1:1<br />

MCR, kW / rpm: 9720/124 10,470/124<br />

CMCR, kW / rpm: 9720/124 9720/124<br />

BMEP at CMCR, bar: 19.5 19.5<br />

CSR at 90% CMCR, kW / rpm: 8748/119.7 8748/119.7<br />

BSFC at CMCR, g/kWh:<br />

– 100% load: 171 165.7<br />

– 90% load: 167.6 163.0<br />

Daily fuel consumption, tonnes/day:<br />

– ISO fuel, LCV 42.7 MJ/kg: 35.2 34.2<br />

– LCV 40.5 MJ/kg: 37.1 36.2<br />

– As percentage, %: 100 97.3 – 2.7%<br />

Annual fuel costs, US$: 4,637,000 4,513,000<br />

Fuel saving, US$: 0 – 124,000<br />

— 10 — © Wärtsilä Corporation, June 2008

![Conceitos transmissao de dados .Sinais[.pdf]](https://img.yumpu.com/50982145/1/190x146/conceitos-transmissao-de-dados-sinaispdf.jpg?quality=85)

![Packages e interfaces[.pdf]](https://img.yumpu.com/50629553/1/190x134/packages-e-interfacespdf.jpg?quality=85)