Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Fuel system: single-point injection models 4A.7<br />

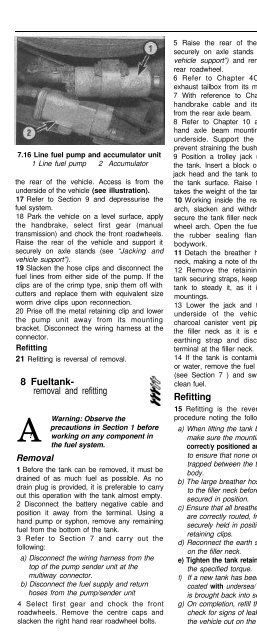

7.16 Line fuel pump and accumulator unit<br />

1 Line fuel pump 2 Accumulator<br />

the rear of the vehicle. Access is from the<br />

underside of the vehicle (see illustration).<br />

17 Refer to Section 9 and depressurise the<br />

fuel system.<br />

18 Park the vehicle on a level surface, apply<br />

the handbrake, select first gear (manual<br />

transmission) and chock the front roadwheels.<br />

Raise the rear of the vehicle and support it<br />

securely on axle stands (see “Jacking and<br />

vehicle support”).<br />

19 Slacken the hose clips and disconnect the<br />

fuel lines from either side of the pump. If the<br />

clips are of the crimp type, snip them off with<br />

cutters and replace them with equivalent size<br />

worm drive clips upon reconnection.<br />

20 Prise off the metal retaining clip and lower<br />

the pump unit away from its mounting<br />

bracket. Disconnect the wiring harness at the<br />

connector.<br />

Refitting<br />

21 Refitting is reversal of removal.<br />

8 Fueltankremoval<br />

and refitting<br />

A<br />

Warning:<br />

!<br />

Removal<br />

Observe the<br />

precautions in Section 1 before<br />

working on any component in<br />

the fuel system.<br />

1 Before the tank can be removed, it must be<br />

drained of as much fuel as possible. As no<br />

drain plug is provided, it is preferable to carry<br />

out this operation with the tank almost empty.<br />

2 Disconnect the battery negative cable and<br />

position it away from the terminal. Using a<br />

hand pump or syphon, remove any remaining<br />

fuel from the bottom of the tank.<br />

3 Refer to Section 7 and carry out the<br />

following:<br />

a) Disconnect the wiring harness from the<br />

top of the pump sender unit at the<br />

multiway connector.<br />

b) Disconnect the fuel supply and return<br />

hoses from the pump/sender unit<br />

4 Select first gear and chock the front<br />

roadwheels. Remove the centre caps and<br />

slacken the right hand rear roadwheel bolts.<br />

5 Raise the rear of the vehicle, support it<br />

securely on axle stands (see “Jacking and<br />

vehicle support”) and remove the right hand<br />

rear roadwheel.<br />

6 Refer to Chapter 4C and unhook the<br />

exhaust tailbox from its mounting bracket.<br />

7 With reference to Chapter 9, detach the<br />

handbrake cable and its mounting bracket<br />

from the rear axle beam.<br />

8 Refer to Chapter 10 and unbolt the right<br />

hand axle beam mounting from the vehicle<br />

underside. Support the axle on blocks to<br />

prevent straining the bushes.<br />

9 Position a trolley jack under the centre of<br />

the tank. Insert a block of wood between the<br />

jack head and the tank to prevent damage to<br />

the tank surface. Raise the jack until it just<br />

takes the weight of the tank.<br />

10 Working inside the rear right hand wheel<br />

arch, slacken and withdraw the screws that<br />

secure the tank filler neck to the inside of the<br />

wheel arch. Open the fuel filler flap and peel<br />

the rubber sealing flange away from the<br />

bodywork.<br />

11 Detach the breather hoses from the filler<br />

neck, making a note of their order of fitment.<br />

12 Remove the retaining screws from the<br />

tank securing straps, keeping one hand on the<br />

tank to steady it, as it is released from its<br />

mountings.<br />

13 Lower the jack and tank away from the<br />

underside of the vehicle; disconnect the<br />

charcoal canister vent pipe from the port on<br />

the filler neck as it is exposed. Locate the<br />

earthing strap and disconnect it from the<br />

terminal at the filler neck.<br />

14 If the tank is contaminated with sediment<br />

or water, remove the fuel lift pump/sender unit<br />

(see Section 7 ) and swill the tank out with<br />

clean fuel.<br />

Refitting<br />

15 Refitting is the reverse of the removal<br />

procedure noting the following points.<br />

a) When lifting the tank back into position<br />

make sure the mounting rubbers are<br />

correct/y positioned and take great care<br />

to ensure that none of the hoses become<br />

trapped between the tank and vehicle<br />

body.<br />

b) The large breather hose must be secured<br />

to the filler neck before the tank is<br />

secured in position.<br />

c) Ensure that all breather pipes and hoses<br />

are correctly routed, free of kinks and<br />

securely held in position with their<br />

retaining clips.<br />

d) Reconnect the earth strap to its terminal<br />

on the filler neck.<br />

e) Tighten the tank retaining strap bolts to<br />

the specified torque.<br />

f) If a new tank has been fitted, it must be<br />

coated with undersea/ before the vehicle<br />

is brought back into service.<br />

g) On completion, refill the tank with fuel and<br />

check for signs of leakage prior to taking<br />

the vehicle out on the road.<br />

2 Refer to Section 5 and locate the fuel pump<br />

relay. Remove the relay from its socket, then<br />

crank the engine for a few seconds. The<br />

engine may fire and run for a while, but<br />

continue cranking until it stops. The fuel<br />

injector should have opened enough times<br />

during cranking to considerably reduce the<br />

line fuel pressure.<br />

3 Switch off the ignition ,then disconnect the<br />

battery negative cable and position it away<br />

from the terminal<br />

4 Place a suitable container beneath the<br />

connection/union that is to be disconnected,<br />

and have a rag ready to soak up any escaping<br />

fuel not being caught by the container.<br />

5 Slowly loosen the connection or union nut<br />

(as applicable) to avoid a sudden release of<br />

pressure and position the rag around the<br />

connection to catch any fuel spray which may<br />

be expelled. Once the pressure has been<br />

released, disconnect the fuel line completely<br />

and insert plugs to minimise fuel loss and to<br />

prevent the entry of dirt into the fuel system.<br />

1 If a fault appears in the fuel injection system<br />

first ensure that all the system wiring<br />

connectors are securely connected and free<br />

of corrosion. Then ensure that the fault is not<br />

due to poor maintenance; ie, check that the<br />

air cleaner filter element is clean, the spark<br />

plugs are in good condition and correctly<br />

gapped, the cylinder compression pressures<br />

are correct, the ignition timing is correct and