Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

10 000 mile/12 month service 1.7<br />

collect in the sump. Continue adding oil a<br />

small quantity at a time until the level is just<br />

above the lower mark on the dipstick. Adding<br />

approximately 1.0 litres will raise the level<br />

from the lower mark to the upper mark on the<br />

dipstick. Refit the filler cap.<br />

14 Start the engine and run it for a few<br />

minutes; check for leaks around the oil filter<br />

seal and the sump drain plug. Note that there<br />

may be a delay of a few seconds before the oil<br />

pressure warning light goes out when the<br />

engine is first started, as the oil circulates<br />

through the engine oil galleries and (where<br />

applicable) the new oil filter before the<br />

pressure builds up. If the oil pressure warning<br />

light does not extinguish after the engine has<br />

started and run for several seconds, stop the<br />

engine immediately and check for leaks<br />

around the components that have been<br />

disturbed.<br />

15 Switch off the engine, and wait a few<br />

minutes for the new oil to settle into the sump.<br />

With the new oil circulated and the filter now<br />

completely full, recheck the level on the<br />

dipstick, and add more oil as necessary.<br />

16 Dispose of the used engine oil safely, with<br />

reference to “General repair procedures” in<br />

the Reference Sections of this manual.<br />

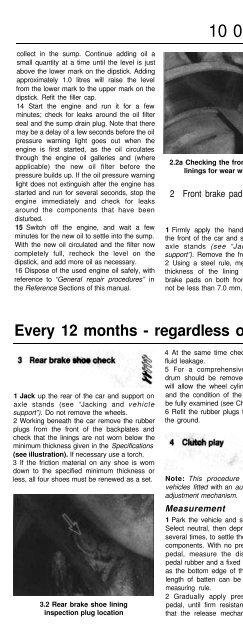

2.2a Checking the front brake outer pad<br />

linings for wear with a steel rule<br />

2 Front brake pad check<br />

1 Firmly apply the handbrake, then jack up<br />

the front of the car and support it securely on<br />

axle stands (see “Jacking and vehicle<br />

support”). Remove the front roadwheels.<br />

2 Using a steel rule, measure the combined<br />

thickness of the lining and backing of the<br />

brake pads on both front brakes. This must<br />

not be less than 7.0 mm. Check the inner pad<br />

2.2b Check the front brake inner pad<br />

linings through the hole in the caliper<br />

through the hole on the front of the caliper<br />

(see illustrations).<br />

3 For a comprehensive check, the brake pads<br />

should be removed and cleaned. The<br />

operation of the caliper can then also be<br />

checked, and the condition of the brake disc<br />

itself can be fully examined on both sides.<br />

Refer to Chapter 9 for further information.<br />

4 If any pad’s friction material is worn to the<br />

specified thickness or less, all four pads must.<br />

be renewed as a set. Refer to Chapter 9.<br />

5 On completion refit the roadwheels and<br />

lower the car to the ground.<br />

Every 12 months - regardless of mileage .<br />

1 Jack up the rear of the car and support on<br />

axle stands (see “Jacking and vehicle<br />

support”). Do not remove the wheels.<br />

2 Working beneath the car remove the rubber<br />

plugs from the front of the backplates and<br />

check that the linings are not worn below the<br />

minimum thickness given in the Specifications<br />

(see illustration). If necessary use a torch.<br />

3 If the friction material on any shoe is worn<br />

down to the specified minimum thickness or<br />

less, all four shoes must be renewed as a set.<br />

3.2 Rear brake shoe lining<br />

inspection plug location<br />

4 At the same time check for signs of brake<br />

fluid leakage.<br />

5 For a comprehensive check, the brake<br />

drum should be removed and cleaned. This<br />

will allow the wheel cylinders to be checked,<br />

and the condition of the brake drum itself to<br />

be fully examined (see Chapter 9).<br />

6 Refit the rubber plugs then lower the car to<br />

the ground.<br />

Note: This procedure does not apply to<br />

vehicles fitted with an automatic clutch cab/e<br />

adjustment mechanism.<br />

Measurement<br />

1 Park the vehicle and switch off the engine.<br />

Select neutral, then depress the clutch pedal<br />

several times, to settle the release mechanism<br />

components. With no pressure applied to the<br />

pedal, measure the distance between the<br />

pedal rubber and a fixed reference point, such<br />

as the bottom edge of the steering wheel - a<br />

length of batten can be used to serve as a<br />

measuring rule.<br />

2 Gradually apply pressure to the clutch<br />

pedal, until firm resistance is felt, indicating<br />

that the release mechanism is beginning to<br />

disengage the clutch. At this point, repeat the<br />

measurement described in paragraph 1.<br />

3 Compare the measurement with the value<br />

listed in the Specifications - if the free play<br />

exceeds the maximum permitted, adjust the<br />

cable as described in the following sub- :<br />

Section.<br />

Adjustment<br />

4 Open the bonnet and locate the clutch<br />

cable adjusting nut, on the upper surface of<br />

the transmission casing.<br />

5 Rotate the nut through half a turn, using a<br />

spanner, to take up the slack in the cable.<br />

Measure the clutch pedal freeplay again, as<br />

described in the previous sub-Section.<br />

6 Repeat the operations described in<br />

paragraphs 4 and 5 until the correct pedal<br />

freeplay is achieved.<br />

5<br />

1 Visually inspect the engine joint faces,<br />

gaskets and seals for any signs of water or oil<br />

leaks. Pay particular attention to the areas<br />

around the camshaft cover, cylinder head, oil<br />

filter and sump joint faces. Bear in mind that,<br />

over a period of time, some very slight<br />

seepage from these areas is to be expected -