Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

10.4 Suspension and steering<br />

Note: VW tool 40-201 B is necessary in order<br />

to unscrew the screw cap from the top of the<br />

strut.<br />

1 A faulty shock absorber will normally make<br />

a knocking noise as the car is driven over<br />

rough surfaces.<br />

2 To remove the shock absorber first remove<br />

the front coil spring as described in Section 3.<br />

3 Using VW tool 40-201 B unscrew the screw<br />

cap from the top of the strut and remove the<br />

piston rod guide and seal. If necessary first<br />

mount the strut in a vice.<br />

4 Pull the shock absorber out of the strut then<br />

pour the remaining fluid out and discard it.<br />

Clean the inside of the strut with paraffin and<br />

wipe dry.<br />

5 Replacement shock absorbers are supplied<br />

as dry type cartridges, the wet type are only<br />

fitted by the factory when new.<br />

6 With the new shock absorber upright,<br />

operate it fully several times and check that<br />

the resistance is even without any tight spots.<br />

7 Insert the shock absorber in the strut and fit<br />

the guide together with a new seal.<br />

8 Fit the screw cap and tighten it to the<br />

specified torque.<br />

9 Refit the coil spring as described in Section<br />

3.<br />

Testing<br />

1 Jack up the front of the car and support on<br />

axle stands (see “Jacking and vehicle<br />

support”). With neutral selected, spin the<br />

wheel. A rumbling noise will be evident if the<br />

bearings are worn and excessive play will be<br />

apparent when the wheel is rocked, however<br />

check that the lower balljoint is not<br />

responsible for the play.<br />

Renewal<br />

2 To renew the wheel bearings first remove<br />

the suspension strut as described in Section<br />

2.<br />

3 Support the outside of the strut, then using<br />

a suitable metal tube, drive the hub from the<br />

wheel bearing. The outer bearing race will be<br />

forced from the bearing during this procedure<br />

and therefore it is not possible to re-use the<br />

bearing.<br />

4 Mount the hub in a vice and use a suitable<br />

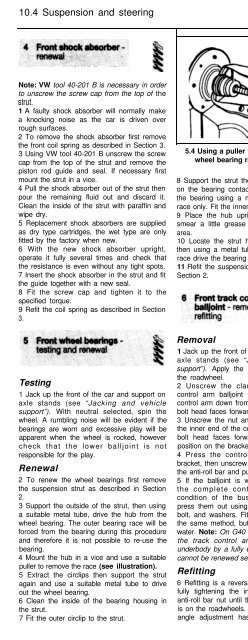

puller to remove the race (see illustration).<br />

5 Extract the circlips then support the strut<br />

again and use a suitable metal tube to drive<br />

out the wheel bearing.<br />

6 Clean the inside of the bearing housing in<br />

the strut.<br />

7 Fit the outer circlip to the strut.<br />

5.4 Using a puller to remove the outer<br />

wheel bearing race from the hub<br />

8 Support the strut then smear a little grease<br />

on the bearing contact surfaces and drive in<br />

the bearing using a metal tube on the outer<br />

race only. Fit the inner circlip.<br />

9 Place the hub upright on the bench and<br />

smear a little grease on the bearing contact<br />

area.<br />

10 Locate the strut horizontally on the hub,<br />

then using a metal tube on the bearing inner<br />

race drive the bearing fully onto the hub.<br />

11 Refit the suspension strut as described in<br />

Section 2.<br />

Removal<br />

1 Jack up the front of the car and support on<br />

axle stands (see “Jacking and vehicle<br />

support”). Apply the handbrake and remove<br />

the roadwheel.<br />

2 Unscrew the clamp bolt securing the<br />

control arm balljoint to the strut. Press the<br />

control arm down from the strut. Note that the<br />

bolt head faces forward.<br />

3 Unscrew the nut and remove the bolt from<br />

the inner end of the control arm. Note that the<br />

bolt head faces forward, and also mark its<br />

position on the bracket.<br />

4 Press the control arm down from the<br />

bracket, then unscrew the nut from the end of<br />

the anti-roll bar and pull off the control arm.<br />

5 If the balljoint is worn excessively, renew<br />

the complete control arm. Check the<br />

condition of the bushes and if necessary<br />

press them out using a metal tube, nut and<br />

bolt, and washers. Fit the new bushes using<br />

the same method, but first dip them in soapy<br />

water. Note: On G40 models the inner end of<br />

the track control arm is attached to the<br />

underbody by a fully enclosed ball joint which<br />

cannot be renewed separately.<br />

Refitting<br />

6 Refitting is a reversal of removal, but delay<br />

fully tightening the inner pivot bolt and the<br />

anti-roll bar nut until the full weight of the car<br />

is on the roadwheels. Note that where camber<br />

angle adjustment has been made, the bolt<br />

Removal<br />

1 Jack up the front of the car and support<br />

with axle stands (see “Jacking and vehicle<br />

support”). Remove both wheels and apply the<br />

handbrake.<br />

2 Note that with the anti-roll bar correctly<br />

fitted, the bend in the front of the bar faces<br />

upwards.<br />

3 Unscrew the bolts and remove the<br />

mounting clamps securing the front of the bar<br />

to the underbody bracket (see illustration).<br />

4 Unscrew and remove the nuts and washers<br />

from the ends of the anti-roll bar.<br />

5 Pull the anti-roll bar from the control arms<br />

and withdraw it from under the car. If difficulty<br />

is experienced, temporarily jack up the control<br />

arms to give a little extra width for the removal<br />

of the bar.<br />

6 Check the bar and rubber bushes for wear<br />

and deterioration and renew as necessary. If<br />

the bush in the control arm is worn, renew it<br />

with reference to Section 6. Note: The bushes<br />

fitted to the G40 model are harder than those<br />

fitted to other models.<br />

Refitting<br />

7.3 Top view of the anti-roll bar<br />

front mounting bracket<br />

(engine removed from car)<br />

hole in the bracket may have been elongated<br />

and in this case it is imperative that the<br />

special bush and bolt are refitted in their<br />

original position otherwise the adjustment will<br />

have to be repeated.<br />

7 Refitting is a reversal of removal, but delay<br />

fully tightening the nuts and bolts until the full<br />

weight of the car is on the roadwheels. The<br />

bend in the front section of the bar must face<br />

upwards. Note that the castor angle is<br />

determined by the position of the control arms<br />

on the anti-roll bar, therefore any adjustment<br />

washers should be refitted in their original<br />

locations.