Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2A.2 Engine in-car repair procedures<br />

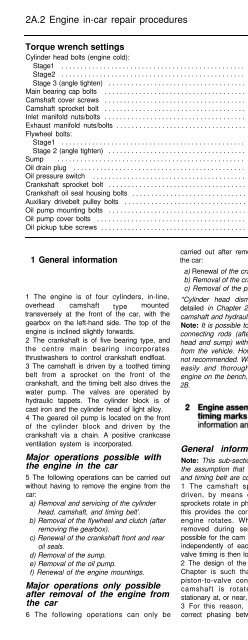

Torque wrench settings Nm Ibf ft<br />

Cylinder head bolts (engine cold):<br />

Stage1 ................................................ 40 30<br />

Stage2 ................................................ 60 44<br />

Stage 3 (angle tighten) .................................... + one half-turn (180”), OR + two quarter-turns (2x90°)<br />

Main bearing cap bolts ..................................... 65 48<br />

Camshaft cover screws ..................................... 10 7<br />

Camshaft sprocket bolt ..................................... 80 59<br />

Inlet manifold nuts/bolts ..................................... 25 18<br />

Exhaust manifold nuts/bolts .................................. 25 18<br />

Flywheel bolts:<br />

Stage1 ................................................ 60 44<br />

Stage 2 (angle tighten) .................................... + 90°<br />

Sump ................................................. 20 15<br />

Oil drain plug ............................................. 30 22<br />

Oil pressure switch ........................................ 25 18<br />

Crankshaft sprocket bolt .................................... 80 59<br />

Crankshaft oil seal housing bolts .............................. 10 7<br />

Auxiliary drivebelt pulley bolts ................................ 20 15<br />

Oil pump mounting bolts .................................... 20 15<br />

Oil pump cover bolts ....................................... 10 7<br />

Oil pickup tube screws ...................................... 10 7<br />

1 General information<br />

1 The engine is of four cylinders, in-line,<br />

overhead camshaft type mounted<br />

transversely at the front of the car, with the<br />

gearbox on the left-hand side. The top of the<br />

engine is inclined slightly forwards.<br />

2 The crankshaft is of five bearing type, and<br />

the centre main bearing incorporates<br />

thrustwashers to control crankshaft endfloat.<br />

3 The camshaft is driven by a toothed timing<br />

belt from a sprocket on the front of the<br />

crankshaft, and the timing belt also drives the<br />

water pump. The valves are operated by<br />

hydraulic tappets. The cylinder block is of<br />

cast iron and the cylinder head of light alloy.<br />

4 The geared oil pump is located on the front<br />

of the cylinder block and driven by the<br />

crankshaft via a chain. A positive crankcase<br />

ventilation system is incorporated.<br />

Major operations possible with<br />

the engine in the car<br />

5 The following operations can be carried out<br />

without having to remove the engine from the<br />

car:<br />

a) Removal and servicing of the cylinder<br />

head, camshaft, and timing belt’.<br />

b) Removal of the flywheel and clutch (after<br />

removing the gearbox).<br />

c) Renewal of the crankshaft front and rear<br />

oil seals.<br />

d) Removal of the sump.<br />

e) Removal of the oil pump.<br />

f) Renewal of the engine mountings.<br />

Major operations only possible<br />

after removal of the engine from<br />

the car<br />

6 The following operations can only be<br />

carried out after removal of the engine from<br />

the car:<br />

a) Renewal of the crankshaft main bearings.<br />

b) Removal of the crankshaft.<br />

c) Removal of the pistons/connecting rods.<br />

*Cylinder head dismantling procedures are<br />

detailed in Chapter 2B and contain details of<br />

camshaft and hydraulic tappet removal.<br />

Note: It is possible to remove the pistons and<br />

connecting rods (after removing the cylinder<br />

head and sump) without removing the engine<br />

from the vehicle. However, this procedure is<br />

not recommended. Work of this nature is more<br />

easily and thorough/y completed with the<br />

engine on the bench, as described in Chapter<br />

2B.<br />

General information<br />

Note: This sub-section has been written with<br />

the assumption that the distributor, HT leads<br />

and timing belt are correctly fitted.<br />

1 The camshaft sprocket is crankshaftdriven,<br />

by means of a timing belt, Both<br />

sprockets rotate in phase with each other and<br />

this provides the correct valve timing as the<br />

engine rotates. When the timing belt is<br />

removed during servicing or repair, it is<br />

possible for the cam and crankshafts to rotate<br />

independently of each other and the correct<br />

valve timing is then lost.<br />

2 The design of the engines covered in this<br />

Chapter is such that potentially damaging<br />

piston-to-valve contact may occur if the<br />

camshaft is rotated when a piston is<br />

stationary at, or near, the top of its stroke.<br />

3 For this reason, it is important that the<br />

correct phasing between the camshaft and<br />

crankshaft is preserved whilst the timing belt<br />

is off the engine. This is achieved by setting<br />

the engine in a reference condition (known as<br />

Top Dead Centre or TDC) before the timing<br />

belt is removed and then preventing the shafts<br />

from rotating until the belt is refitted. Similarly,<br />

if the engine has been dismantled for<br />

overhaul, the engine can be set to TDC during<br />

reassembly to ensure that the correct shaft<br />

phasing is restored.<br />

4 TDC is the highest position a piston<br />

reaches within its respective cylinder - in a<br />

four stroke engine, each piston reaches TDC<br />

twice per cycle; once on the compression<br />

stroke and once on the exhaust stroke. In<br />

general, TDC normally refers to cylinder No 1<br />

on the compression stroke. (Note that the<br />

cylinders are numbered one to four from the<br />

timing belt end of the engine).<br />

5 The crankshaft sprocket is equipped with a<br />

marking which, when aligned with a reference<br />

marking on the timing belt cover, indicates<br />

that cylinder No 1 (and hence also No 4) is at<br />

TDC.<br />

6 The camshaft sprocket is also equipped<br />

with a timing mark - when this is similarly<br />

aligned, the engine is correctly positioned and<br />

the timing belt can then be refitted and<br />

tensioned.<br />

7 The following sub-Sections describe setting<br />

the engine to TDC on cylinder No 1.<br />

Setting engine to TDC on<br />

cylinder No 1 - timing be/t fitted<br />

8 Before starting work, disconnect the battery<br />

negative cable to disable the fuel ignition and<br />

ignition system and to remove the risk of<br />

electrical short circuits. Prevent any vehicle<br />

movement by putting the transmission in<br />

neutral, applying the parking brake and<br />

chocking the rear wheels.<br />

9 On the distributor cap, note the position of<br />

the No 1 cylinder HT terminal. On some<br />

models, the manufacturer provides a marking