Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

5B.4 Ignition systems<br />

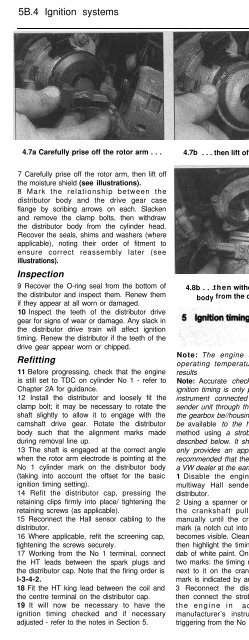

4.7a Carefully prise off the rotor arm . . .<br />

7 Carefully prise off the rotor arm, then lift off<br />

the moisture shield (see illustrations).<br />

8 Mark the relationship between the<br />

distributor body and the drive gear case<br />

flange by scribing arrows on each. Slacken<br />

and remove the clamp bolts, then withdraw<br />

the distributor body from the cylinder head.<br />

Recover the seals, shims and washers (where<br />

applicable), noting their order of fitment to<br />

ensure correct reassembly later (see<br />

illustrations).<br />

Inspection<br />

9 Recover the O-ring seal from the bottom of<br />

the distributor and inspect them. Renew them<br />

if they appear at all worn or damaged.<br />

10 Inspect the teeth of the distributor drive<br />

gear for signs of wear or damage. Any slack in<br />

the distributor drive train will affect ignition<br />

timing. Renew the distributor if the teeth of the<br />

drive gear appear worn or chipped.<br />

Refitting<br />

11 Before progressing, check that the engine<br />

is still set to TDC on cylinder No 1 - refer to<br />

Chapter 2A for guidance.<br />

12 Install the distributor and loosely fit the<br />

clamp bolt; it may be necessary to rotate the<br />

shaft slightly to allow it to engage with the<br />

camshaft drive gear. Rotate the distributor<br />

body such that the alignment marks made<br />

during removal line up.<br />

13 The shaft is engaged at the correct angle<br />

when the rotor arm electrode is pointing at the<br />

No 1 cylinder mark on the distributor body<br />

(taking into account the offset for the basic<br />

ignition timing setting).<br />

14 Refit the distributor cap, pressing the<br />

retaining clips firmly into place/ tightening the<br />

retaining screws (as applicable).<br />

15 Reconnect the Hall sensor cabling to the<br />

distributor.<br />

16 Where applicable, refit the screening cap,<br />

tightening the screws securely.<br />

17 Working from the No 1 terminal, connect<br />

the HT leads between the spark plugs and<br />

the distributor cap. Note that the firing order is<br />

l-3-4-2.<br />

18 Fit the HT king lead between the coil and<br />

the centre terminal on the distributor cap.<br />

19 It will now be necessary to have the<br />

ignition timing checked and if necessary<br />

adjusted - refer to the notes in Section 5.<br />

4.7b . . . then lift off the moisture shield 4.8a Slacken and remove<br />

the clamp bolts . . .<br />

4.8b . . .then withdraw the distributor<br />

body from the cylinder head . . .<br />

Note: The engine should be at normal<br />

operating temperature to ensure correct<br />

results<br />

Note: Accurate checking and setting of the<br />

ignition timing is only possible using a special<br />

instrument connected to the flywheel TDC<br />

sender unit through the aperture in the top of<br />

the gearbox be//housing. This will not normally<br />

be available to the home mechanic, so a<br />

method using a stroboscopic timing light is<br />

described below. It should be noted that this<br />

only provides an approximate setting - it is<br />

recommended that the vehicle be checked by<br />

a VW dealer at the earliest opportunity.<br />

1 Disable the engine by unplugging the<br />

multiway Hall sender connector from the<br />

distributor.<br />

2 Using a spanner or socket and wrench on<br />

the crankshaft pulley, turn the engine<br />

manually until the crankshaft pulley timing<br />

mark (a notch cut into the edge of the pulley)<br />

becomes visible. Clean the edge of the pulley,<br />

then highlight the timing mark with chalk or a<br />

dab of white paint. On G40 models, there are<br />

two marks: the timing mark has a ‘Z’ stamped<br />

next to it on the crankshaft pulley (the TDC<br />

mark is indicated by an ‘0’).<br />

3 Reconnect the distributor multiway plug,<br />

then connect the stroboscopic timing light to<br />

the engine in accordance with the<br />

manufacturer’s instructions, so that it is<br />

triggering from the No 1 cylinder HT lead.<br />

4.8c Recover the seals<br />

4 Start the engine and run it at idling speed.<br />

Direct the beam from the timing light at the<br />

pointer protruding from the timing belt cover.<br />

The stroboscopic effect should ‘freeze’ the<br />

motion of the crankshaft pulley and the<br />

highlighted timing mark. If the mark appears<br />

to be moving back and forth, this may be due<br />

erratic idling - check that all of the cars<br />

electrical accessories are switched off and<br />

that the auxiliary cooling fan is not running.<br />

The engine should be at normal operating<br />

temperature, but the idle speed may be<br />

become unstable if it is particularly hot day<br />

and the engine has been idling for some time.<br />

5 The highlighted timing mark should appear<br />

to be stationary and aligned with the pointer<br />

on the timing belt cover (see illustrations). If<br />

they are not aligned, the basic ignition setting<br />

requires adjustment.<br />

6 To adjust the basic ignition timing setting,<br />

first switch off the engine, to avoid the risk of<br />

a getting a shock from the HT voltage. Refer<br />

5.5a Ignition timing marks -<br />

all models except G40