Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 7<br />

Manual transmission<br />

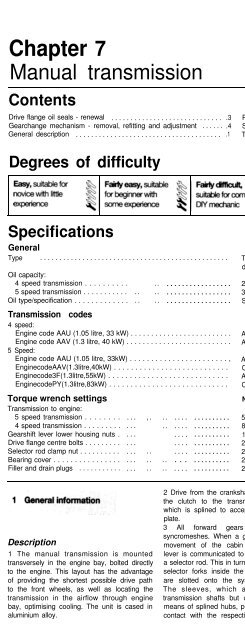

<strong>Contents</strong><br />

Drive flange oil seals - renewal ............................. .3 Reversing lamp switch - testing, removal and refitting ........... .5<br />

Gearchange mechanism - removal, refitting and adjustment ...... .4 Speedometer drive - removal and refitting ..................... .6<br />

General description ...................................... .1 Transmission - removal and refitting ......................... .2<br />

Degrees of difficulty<br />

Specifications<br />

General<br />

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Oil capacity:<br />

4 speed transmission . . . . . . . . . . . . .................<br />

5 speed transmission . . . . . . . . . . . . . . . .................<br />

Oil type/specification . . . . . . . . . . . . . . . . . .................<br />

Transmission codes<br />

4 speed:<br />

Engine code AAU (1.05 litre, 33 kW) . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Engine code AAV (1.3 litre, 40 kW) . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

5 Speed:<br />

Engine code AAU (1.05 litre, 33kW) . . . . . . . . . . . . . . . . . . . . . . . ,<br />

EnginecodeAAV(1.3litre,40kW) . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Enginecode3F(1.3litre,55kW) . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

EnginecodePY(1.3litre,83kW) . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Torque wrench settings<br />

Transmission to engine:<br />

5 speed transmission . . . . . . . .<br />

4 speed transmission . . . . . . . . .<br />

Gearshift lever lower housing nuts .<br />

Drive flange centre bolts . . . . . . . . .<br />

Selector rod clamp nut . . . . . . . . . .<br />

Bearing cover . . . . . . . . . . . . . . . .<br />

Filler and drain plugs . . . . . . . . . . .<br />

. . .<br />

. . .<br />

. . .<br />

. . .<br />

. . .<br />

. . .<br />

. . .<br />

, .<br />

. .<br />

. .<br />

. .<br />

. .<br />

. .<br />

. .<br />

. .<br />

Transverse mounted, front wheel drive layout with integral transaxle<br />

differential/final drive. 4 or 5 forward speeds,1 reverse speed<br />

2.2 litres<br />

3.1 litres<br />

See end of “weekly checks”<br />

AKV, AKY, CEL, CEN<br />

AKY, CEL<br />

AHZ, AYZ, CEE, CEM<br />

CEG, 8P<br />

AHD, CEH<br />

CEK, ATV<br />

Nm<br />

Ibf ft<br />

. . . . .......... 55 41<br />

. . . . .......... 80 59<br />

. . . . .......... 15 11<br />

. . . . .......... 25 18<br />

. . . . .......... 20 15<br />

. . . .......... 20 15<br />

. . . . .......... 25 18<br />

Description<br />

1 The manual transmission is mounted<br />

transversely in the engine bay, bolted directly<br />

to the engine. This layout has the advantage<br />

of providing the shortest possible drive path<br />

to the front wheels, as well as locating the<br />

transmission in the airflow through engine<br />

bay, optimising cooling. The unit is cased in<br />

aluminium alloy.<br />

2 Drive from the crankshaft is transmitted via<br />

the clutch to the transmission input shaft,<br />

which is splined to accept the clutch driven<br />

plate.<br />

3 All forward gears are fitted with<br />

syncromeshes. When a gear is selected, the<br />

movement of the cabin floor-mounted gear<br />

lever is communicated to the transmission by<br />

a selector rod. This in turn actuates a series of<br />

selector forks inside the transmission which<br />

are slotted onto the synchromesh sleeves.<br />

The sleeves, which are locked to the<br />

transmission shafts but can slide axially by<br />

means of splined hubs, press baulk rings into<br />

contact with the respective gear/pinion. The<br />

coned surfaces between the baulk rings and<br />

the pinion/gear act as a friction clutch, that<br />

progressively matches the speed of the<br />

synchromesh sleeve (and hence the<br />

transmission shaft) with that of the<br />

gear/pinion. The dog teeth on the outside of<br />

the baulk ring prevent the synchromesh<br />

sleeve ring from meshing with the gear/pinion<br />

until their speeds are exactly matched; this<br />

allows gear changes to be carried out<br />

smoothly and greatly reduces the noise and<br />

mechanical wear caused by rapid gear<br />

changes.<br />

4 Drive is transmitted to the differential<br />

crownwheel, which rotates the differential