Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2B.10 Engine removal and overhaul procedures<br />

5.18 Checking the piston ring<br />

side clearance<br />

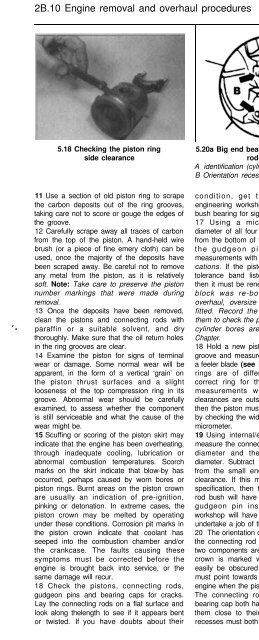

5.20a Big end bearing cap and connecting<br />

rod markings<br />

A identification (cylinder number) markings<br />

B Orientation recesses<br />

5.20b Orientation arrow on piston crown<br />

(highlighted)<br />

11 Use a section of old piston ring to scrape<br />

the carbon deposits out of the ring grooves,<br />

taking care not to score or gouge the edges of<br />

the groove.<br />

12 Carefully scrape away all traces of carbon<br />

from the top of the piston. A hand-held wire<br />

brush (or a piece of fine emery cloth) can be<br />

used, once the majority of the deposits have<br />

been scraped away. Be careful not to remove<br />

any metal from the piston, as it is relatively<br />

soft. Note: Take care to preserve the piston<br />

number markings that were made during<br />

removal.<br />

13 Once the deposits have been removed,<br />

clean the pistons and connecting rods with<br />

paraffin or a suitable solvent, and dry<br />

thoroughly. Make sure that the oil return holes<br />

in the ring grooves are clear.<br />

14 Examine the piston for signs of terminal<br />

wear or damage. Some normal wear will be<br />

apparent, in the form of a vertical ‘grain’ on<br />

the piston thrust surfaces and a slight<br />

looseness of the top compression ring in its<br />

groove. Abnormal wear should be carefully<br />

examined, to assess whether the component<br />

is still serviceable and what the cause of the<br />

wear might be.<br />

15 Scuffing or scoring of the piston skirt may<br />

indicate that the engine has been overheating,<br />

through inadequate cooling, lubrication or<br />

abnormal combustion temperatures. Scorch<br />

marks on the skirt indicate that blow-by has<br />

occurred, perhaps caused by worn bores or<br />

piston rings. Burnt areas on the piston crown<br />

are usually an indication of pre-ignition,<br />

pinking or detonation. In extreme cases, the<br />

piston crown may be melted by operating<br />

under these conditions. Corrosion pit marks in<br />

the piston crown indicate that coolant has<br />

seeped into the combustion chamber and/or<br />

the crankcase. The faults causing these<br />

symptoms must be corrected before the<br />

engine is brought back into service, or the<br />

same damage will recur.<br />

18 Check the pistons, connecting rods,<br />

gudgeon pins and bearing caps for cracks.<br />

Lay the connecting rods on a flat surface and<br />

look along thelength to see if it appears bent<br />

or twisted. If you have doubts about their<br />

condition, get them measured at an<br />

engineering workshop. Inspect the small end<br />

bush bearing for signs of wear or cracking.<br />

17 Using a micrometer, measure the<br />

diameter of all four pistons at a point 10 mm<br />

from the bottom of the skirt, at right angles to<br />

the gudgeon pin axis. Compare the<br />

measurements with those listed in the Specifications.<br />

If the piston diameter is out of the<br />

tolerance band listed for its particular size,<br />

then it must be renewed. Note: If the cylinder<br />

block was re-bored during a previous<br />

overhaul, oversize pistons may have been<br />

fitted. Record the measurements and use<br />

them to check the piston clearances when the<br />

cylinder bores are measured, later in this<br />

Chapter.<br />

18 Hold a new piston ring in the appropriate<br />

groove and measure the side clearance using<br />

a feeler blade (see illustration). Note that the<br />

rings are of different widths, so use the<br />

correct ring for the groove. Compare the<br />

measurements with those listed; if the<br />

clearances are outside of the tolerance band,<br />

then the piston must be renewed. Confirm this<br />

by checking the width of the piston ring with a<br />

micrometer.<br />

19 Using internal/external vernier callipers,<br />

measure the connecting rod small end internal<br />

diameter and the gudgeon pin external<br />

diameter. Subtract the gudgeon pin diameter<br />

from the small end diameter to obtain the<br />

clearance. If this measurement is outside its<br />

specification, then the piston and connecting<br />

rod bush will have to be resized and a new<br />

gudgeon pin installed. An engineering<br />

workshop will have the equipment needed to<br />

undertake a job of this nature.<br />

20 The orientation of the piston with respect to<br />

the connecting rod must be correct when the<br />

two components are reassembled. The piston<br />

crown is marked with an arrow (which can<br />

easily be obscured by carbon deposits); this<br />

must point towards the timing belt end of the<br />

engine when the piston is installed in the bore.<br />

The connecting rod and its corresponding<br />

bearing cap both have recesses machined into<br />

them close to their mating surfaces - these<br />

recesses must both face in the same direction<br />

as the arrow on the piston crown (ie towards the<br />

timing belt end of the engine) when correctly<br />

installed (see illustrations). Reassemble the<br />

two components to satisfy this requirement.<br />

21 Lubricate the gudgeon pin and small end<br />

bush with clean engine oil. Slide the pin into<br />

the piston, engaging the connecting rod small<br />

end. Fit two new circlips to the piston at either<br />

end of the gudgeon pin, so that their open<br />

ends are facing 180° away from the removal<br />

slot in the piston. Repeat this operation for the<br />

remaining pistons.<br />

Removal<br />

1 Note: If no work is to be done on the<br />

pistons and connecting rods, then removal the<br />

cylinder head and pistons will not be<br />

necessary. Instead, the pistons need only be<br />

pushed far enough up the bores so that they<br />

are positioned clear of the crankpins. The use<br />

of an engine stand is strongly recommended.<br />

2 With reference to Chapter 2A, carry out the<br />

following:<br />

a) Remove the crankshaft timing belt<br />

sprocket.<br />

b) Remove the clutch components and<br />

flywheel.<br />

c) Remove the sump, baffle plate, oil pump<br />

and pickup.<br />

d) Remove the front and rear crankshaft oil<br />

seals and their housings.<br />

3 Unbolt the pistons and connecting rods<br />

from the crankpins, as described in Section 5<br />

(refer to the Note above).<br />

4 Carry out a check of the crankshaft endfloat,<br />

as follows. Note: This can only be<br />

accomplished when the crankshaft is still<br />

installed in the cylinder block/crankcase, but is<br />

free to move. Set up a DTI gauge so that the<br />

probe is in line with the crankshaft axis and is<br />

in contact with a fixed point on end of the<br />

crankshaft. Push the crankshaft along its axis<br />

to the end of its travel, and then zero the