Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

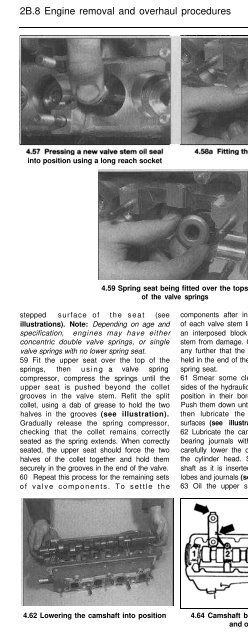

2B.8 Engine removal and overhaul procedures<br />

into position using a long reach socket<br />

4.59 Spring seat being fitted over the tops<br />

of the valve springs<br />

4.61 Refitting the hydraulic tappets<br />

stepped surface of the seat (see<br />

illustrations). Note: Depending on age and<br />

specification, engines may have either<br />

concentric double valve springs, or single<br />

valve springs with no lower spring seat.<br />

59 Fit the upper seat over the top of the<br />

springs, then using a valve spring<br />

compressor, compress the springs until the<br />

upper seat is pushed beyond the collet<br />

grooves in the valve stem. Refit the split<br />

collet, using a dab of grease to hold the two<br />

halves in the grooves (see illustration).<br />

Gradually release the spring compressor,<br />

checking that the collet remains correctly<br />

seated as the spring extends. When correctly<br />

seated, the upper seat should force the two<br />

halves of the collet together and hold them<br />

securely in the grooves in the end of the valve.<br />

60 Repeat this process for the remaining sets<br />

of valve components. To settle the<br />

components after installation, strike the end<br />

of each valve stem lightly with a mallet, using<br />

an interposed block of wood to protect the<br />

stem from damage. Check before progressing<br />

any further that the split collets remain firmly<br />

held in the end of the valve stem by the upper<br />

spring seat.<br />

61 Smear some clean engine oil onto the<br />

sides of the hydraulic tappets and fit them into<br />

position in their bores in the cylinder head.<br />

Push them down until they contact the valves,<br />

then lubricate the camshaft lobe contact<br />

surfaces (see illustration).<br />

62 Lubricate the camshaft and cylinder head<br />

bearing journals with clean engine oil, then<br />

carefully lower the camshaft into position on<br />

the cylinder head. Support the ends of the<br />

shaft as it is inserted, to avoid damaging the<br />

lobes and journals (see illustration).<br />

63 Oil the upper surfaces of the camshaft<br />

bearing journals, then fit the bearing caps in<br />

place. Ensure that they are fitted the right way<br />

around and in the correct locations, then fit<br />

and tighten the retaining nuts, as follows:<br />

64 The bearing caps have their respective<br />

cylinder numbers stamped onto them and<br />

have an elongated lug on one side. When<br />

correctly fitted, the numbers should be<br />

readable from the exhaust side of the cylinder<br />

head and the lugs should face the inlet side of<br />

the cylinder head (see illustration).<br />

65 Fit caps Nos 2 and 4 over the camshaft<br />

and tighten the retaining nuts alternately and<br />

diagonally to the specified first stage torque<br />

(see illustration).<br />

66 Smear the cylinder head mating surfaces<br />

of caps Nos 1 and 5 with suitable sealant then<br />

fit them, together with cap No 3, over the<br />

camshaft and tighten the nuts to the specified<br />

first stage torque.<br />

4.62 Lowering the camshaft into position 4.64 Camshaft bearing cap markings 4.65 Tightening the camshaft<br />

and orientation<br />

bearing cap nuts