Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

7.4 Manual transmission<br />

Testing<br />

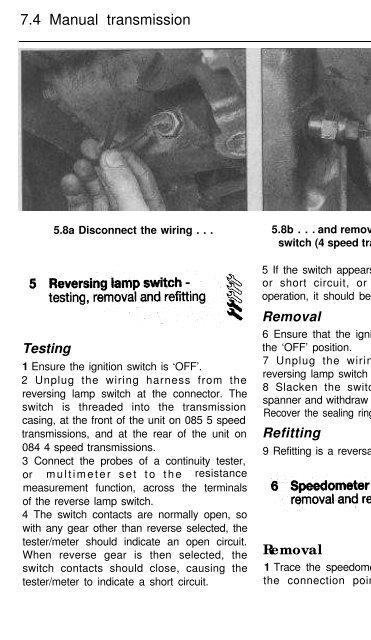

5.8a Disconnect the wiring . . .<br />

1 Ensure the ignition switch is ‘OFF’.<br />

2 Unplug the wiring harness from the<br />

reversing lamp switch at the connector. The<br />

switch is threaded into the transmission<br />

casing, at the front of the unit on 085 5 speed<br />

transmissions, and at the rear of the unit on<br />

084 4 speed transmissions.<br />

3 Connect the probes of a continuity tester,<br />

or multimeter set to the resistance<br />

measurement function, across the terminals<br />

of the reverse lamp switch.<br />

4 The switch contacts are normally open, so<br />

with any gear other than reverse selected, the<br />

tester/meter should indicate an open circuit.<br />

When reverse gear is then selected, the<br />

switch contacts should close, causing the<br />

tester/meter to indicate a short circuit.<br />

5.8b . . . and remove the reversing light<br />

switch (4 speed transmission shown)<br />

5 If the switch appears to be constantly open<br />

or short circuit, or is intermittent in its<br />

operation, it should be renewed.<br />

Removal<br />

6 Ensure that the ignition switch is turned to<br />

the ‘OFF’ position.<br />

7 Unplug the wiring harness from the<br />

reversing lamp switch at the connector.<br />

8 Slacken the switch body using a ring<br />

spanner and withdraw it from the transmission.<br />

Recover the sealing ring. (see illustrations).<br />

Refitting<br />

9 Refitting is a reversal of removal.<br />

Removal<br />

1 Trace the speedometer drive cable back to<br />

the connection point on the differential<br />

6.2 Speedometer drive cable locknut<br />

(arrowed) at the differential casing<br />

housing, at the rear of the transmission<br />

casing.<br />

2 Unscrew the locknut and withdraw the end<br />

of the drive cable (see illustration). Where<br />

fitted, recover the washer.<br />

3 Using a ring spanner, unscrew and<br />

withdraw the speedometer drive guide sleeve.<br />

4 Remove the drive shaft and gear from the<br />

transmission casing.<br />

5 Clean the gear thoroughly and examine the<br />

teeth for signs of wear or damage. Renew the<br />

component if necessary, but bear in mind that<br />

the drive pinion inside the differential casing<br />

may be worn as well and this can only be<br />

renewed as part of a complete transmission<br />

overhaul.<br />

Refitting<br />

6 Refitting is a reversal of removal.