Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2A.4 Engine in-car repair procedures<br />

manufacturer. Note the lower compression<br />

ratio of the supercharged G40 model (engine<br />

code PY).<br />

9 If the pressure in any cylinder is low, carry<br />

out the following test to isolate the cause.<br />

Introduce a teaspoonful of clean oil into that<br />

cylinder through its spark plug hole, and<br />

repeat the test.<br />

10 If the addition of oil temporarily improves<br />

the compression pressure, this indicates that<br />

bore or piston wear is responsible for the<br />

pressure loss. No improvement suggests that<br />

leaking or burnt valves, or a blown head<br />

gasket, may be to blame.<br />

11 A low reading from two adjacent cylinders<br />

is almost certainly due to the head gasket<br />

having blown between them: the presence of<br />

coolant in the engine oil will confirm this.<br />

12 If one cylinder is about 20 percent lower<br />

than the others and the engine has a slightly<br />

rough idle, a worn camshaft lobe could be the<br />

cause.<br />

13 If the compression reading is unusually<br />

high, the combustion chambers are probably<br />

coated with carbon deposits. If this is the<br />

case, the cylinder head should be removed<br />

and decarbonised.<br />

14 On completion of the test, refit the spark<br />

plugs and restore the ignition system.<br />

General information<br />

1 The primary function of the toothed timing<br />

belt is to drive the camshaft(s), but it is also<br />

used to drive the coolant pump. Should the<br />

belt slip or break in service, the valve timing will<br />

be disturbed and piston to valve contact may<br />

occur, resulting in serious engine damage.<br />

2 For this reason, it is important that the<br />

timing belt is tensioned correctly and<br />

inspected regularly for signs of wear or<br />

deterioration.<br />

Removal<br />

3 Disconnect the battery negative cable and<br />

position it away from the terminal.<br />

4 With reference to Section 2, remove the<br />

timing belt outer cover and set the engine to<br />

TDC on cylinder No1 .<br />

5 If the timing belt is relatively new and is to<br />

be refitted later, check to see if it has<br />

manufacturers markings to indicate the<br />

correct direction of rotation. If none are<br />

present, make your own using a dab of paint<br />

or typists correction fluid.<br />

Caution: If the belt is refitted differently,<br />

accelerated wear leading to premature<br />

failure may occur.<br />

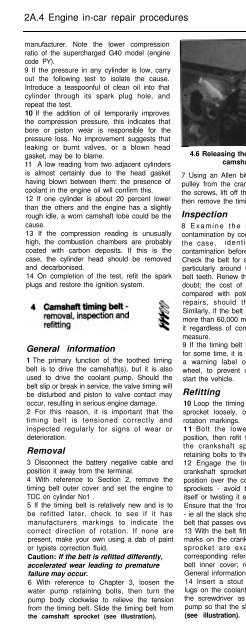

6 With reference to Chapter 3, loosen the<br />

water pump retaining bolts, then turn the<br />

pump body clockwise to relieve the tension<br />

from the timing belt. Slide the timing belt from<br />

the camshaft sprocket (see illustration).<br />

4.6 Releasing the timing belt from the<br />

camshaft sprocket<br />

7 Using an Allen bit, unbolt the auxiliary belt<br />

pulley from the crankshaft sprocket. Remove<br />

the screws, lift off the timing belt lower cover,<br />

then remove the timing belt.<br />

Inspection<br />

8 Examine the belt for evidence of<br />

contamination by coolant or lubricant. If this is<br />

the case, identify the source of the<br />

contamination before progressing any further.<br />

Check the belt for signs of wear or damage,<br />

particularly around the leading edges of the<br />

belt teeth. Renew the belt if its condition is in<br />

doubt; the cost of belt renewal is negligible<br />

compared with potential cost of the engine<br />

repairs, should the belt fail in service.<br />

Similarly, if the belt is known to have covered<br />

more than 60,000 miles, it is prudent to renew<br />

it regardless of condition, as a precautionary<br />

measure.<br />

9 If the timing belt is not going to be refitted<br />

for some time, it is a wise precaution to hang<br />

a warning label on the vehicles’ steering<br />

wheel, to prevent others from attempting to<br />

start the vehicle.<br />

Refitting<br />

10 Loop the timing belt under the crankshaft<br />

sprocket loosely, observing the direction of<br />

rotation markings.<br />

11 Bolt the lower timing belt cover in<br />

position, then refit the auxiliary belt pulley to<br />

the crankshaft sprocket and tighten the<br />

retaining bolts to the specified torque.<br />

12 Engage the timing belt teeth with the<br />

crankshaft sprocket, then manoeuvre it into<br />

position over the coolant pump and camshaft<br />

sprockets - avoid bending the belt back on<br />

itself or twisting it excessively as you do this.<br />

Ensure that the ‘front run’ of the belt is taught<br />

- ie all the slack should be in the section of the<br />

belt that passes over the coolant pump pulley.<br />

13 With the belt fitted, ensure that the timing<br />

marks on the crankshaft pulley and camshaft<br />

sprocket are exactly aligned with their<br />

corresponding reference marks on the timing<br />

belt inner cover; refer to the illustrations in<br />

General information for details.<br />

14 Insert a stout screwdriver between the<br />

lugs on the coolant pump casting, then using<br />

the screwdriver as a lever, turn the coolant<br />

pump so that the slack in the belt is taken up<br />

(see illustration).<br />

4.14 Adjusting the timing belt tension by<br />

rotating the coolant pump<br />

15 Test the belt tension by grasping it<br />

between the fingers at a point mid-way<br />

between the coolant pump and camshaft<br />

sprockets and twisting it; the belt tension is<br />

correct when it can just be twisted through<br />

90° (quarter of a turn) and no further (see<br />

illustration).<br />

16 When the correct belt tension has been<br />

achieved, tighten the coolant pump mounting<br />

bolts to the specified torque.<br />

17 Using a spanner or wrench and socket on<br />

the crankshaft sprocket centre bolt, rotate the<br />

crankshaft through two complete revolutions<br />

and reset the engine to TDC on cylinder No1 ,<br />

with reference to Section 2. Re-check the belt<br />

tension, adjusting it if necessary.<br />

18 Refit the timing belt cover and fasten the<br />

retaining clips securely.<br />

Camshaft sprocket<br />

Removal<br />

1 With reference to Section 2 remove the<br />

timing belt cover, set the engine to TDC on<br />

cylinder No1 and remove the timing belt.<br />

2 The camshaft sprocket must be held<br />

stationary whilst its retaining bolt is<br />

4.15 Testing the timing belt tension