Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

,<br />

9.8 Braking system<br />

Removal<br />

1 Apply the handbrake, then jack up the front<br />

of the vehicle and support it on axle stands<br />

(see “Jacking and vehicle support”). Remove<br />

the appropriate roadwheel.<br />

2 Minimise fluid loss by first removing the<br />

master cylinder reservoir cap, and then<br />

tightening it down onto a piece of polythene,<br />

to obtain an airtight seal. Alternatively, use a<br />

brake hose clamp, a G-clamp or a similar tool<br />

to clamp the flexible hose.<br />

3 Clean the area around the union, then<br />

loosen the brake hose union nut.<br />

4 Follow the procedure described in Section<br />

4 for the removal of the brake pads, however<br />

leave the pads in the carrier bracket.<br />

5 Unscrew the caliper from the end of the<br />

brake hose and remove it from the vehicle.<br />

Overhaul<br />

6 With the caliper on the bench, wipe away all<br />

traces of dust and dirt, but avoid inhaling the<br />

dust, as it is injurious to health.<br />

7 Withdraw the partially ejected piston from<br />

the caliper body, and remove the dust seal.<br />

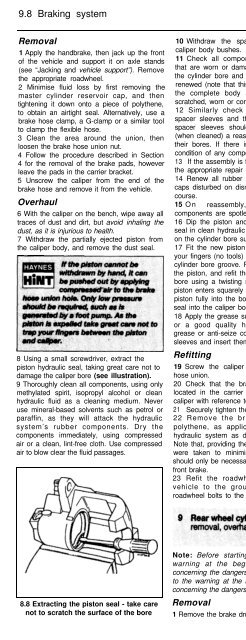

8 Using a small screwdriver, extract the<br />

piston hydraulic seal, taking great care not to<br />

damage the caliper bore (see illustration).<br />

9 Thoroughly clean all components, using only<br />

methylated spirit, isopropyl alcohol or clean<br />

hydraulic fluid as a cleaning medium. Never<br />

use mineral-based solvents such as petrol or<br />

paraffin, as they will attack the hydraulic<br />

system’s rubber components. Dry the<br />

components immediately, using compressed<br />

air or a clean, lint-free cloth. Use compressed<br />

air to blow clear the fluid passages.<br />

8.8 Extracting the piston seal - take care<br />

not to scratch the surface of the bore<br />

10 Withdraw the spacers/sleeves from the<br />

caliper body bushes.<br />

11 Check all components, and renew any<br />

that are worn or damaged. Check particularly<br />

the cylinder bore and piston; these should be<br />

renewed (note that this means the renewal of<br />

the complete body assembly) if they are<br />

scratched, worn or corroded in any way.<br />

12 Similarly check the condition of the<br />

spacer sleeves and their bushes/bores; both<br />

spacer sleeves should be undamaged and<br />

(when cleaned) a reasonably tight sliding fit in<br />

their bores. If there is any doubt about the<br />

condition of any component, renew it.<br />

13 If the assembly is fit for further use, obtain<br />

the appropriate repair kit.<br />

14 Renew all rubber seals, dust covers and<br />

caps disturbed on dismantling as a matter of<br />

course.<br />

15 On reassembly, ensure that all<br />

components are spotlessly clean.<br />

16 Dip the piston and the new piston (fluid)<br />

seal in clean hydraulic fluid. Smear clean fluid<br />

on the cylinder bore surface.<br />

17 Fit the new piston (fluid) seal, using only<br />

your fingers (no tools) to manipulate it into the<br />

cylinder bore groove. Fit the new dust seal to<br />

the piston, and refit the piston to the cylinder<br />

bore using a twisting motion; ensure that the<br />

piston enters squarely into the bore. Press the<br />

piston fully into the bore, then press the dust<br />

seal into the caliper body.<br />

18 Apply the grease supplied in the repair kit,<br />

or a good quality high-temperature brake<br />

grease or anti-seize compound, to the spacer<br />

sleeves and insert them into their bushes.<br />

Refitting<br />

19 Screw the caliper fully onto the flexible<br />

hose union.<br />

20 Check that the brake pads are correctly<br />

located in the carrier bracket, then refit the<br />

caliper with reference to Section 4.<br />

21 Securely tighten the brake hose union nut.<br />

22 Remove the brake hose clamp or<br />

polythene, as applicable, and bleed the<br />

hydraulic system as described in Section 2.<br />

Note that, providing the precautions described<br />

were taken to minimise brake fluid loss, it<br />

should only be necessary to bleed the relevant<br />

front brake.<br />

23 Refit the roadwheel, then lower the<br />

vehicle to the ground and tighten the<br />

roadwheel bolts to the specified torque.<br />

Note: Before starting work, refer to the<br />

warning at the beginning of Section 2<br />

concerning the dangers of hydraulic fluid, and<br />

to the warning at the beginning of Section 5<br />

concerning the dangers of asbestos dust.<br />

Removal<br />

1 Remove the brake drum (see Section 7).<br />

2 Using pliers, carefully unhook the upper<br />

brake shoe return spring, and remove it from<br />

both brake shoes. Pull the upper ends of the<br />

shoes away from the wheel cylinder to<br />

disengage them from the pistons.<br />

3 Minimise fluid loss by first removing the<br />

master cylinder reservoir cap, and then<br />

tightening it down onto a piece of polythene,<br />

to obtain an airtight seal. Alternatively, use a<br />

brake hose clamp, G-clamp or a similar tool to<br />

clamp the flexible hose at the nearest<br />

convenient point to the wheel cylinder.<br />

4 Wipe away all traces of dirt around the<br />

brake pipe union at the rear of the wheel<br />

cylinder, and unscrew the union nut. Carefully<br />

ease the pipe out of the wheel cylinder, and<br />

plug or tape over its end to prevent dirt entry.<br />

Wipe off any spilt fluid immediately.<br />

5 Unscrew the two wheel cylinder retaining<br />

bolts from the rear of the backplate, and<br />

remove the cylinder, taking great care not to<br />

allow surplus hydraulic fluid to contaminate<br />

the brake shoe linings.<br />

Overhaul<br />

6 Brush the dirt and dust from the wheel<br />

cylinder, but take care not to inhale it.<br />

7 Pull the rubber dust seals from the ends of<br />

the cylinder body.<br />

8 The pistons will normally be ejected by the<br />

pressure of the coil spring, but if they are not,<br />

tap the end of the cylinder body on a piece of<br />

wood, or apply low air pressure - eg, from a<br />

foot pump - to the hydraulic fluid union hole to<br />

eject the pistons from their bores.<br />

9 Inspect the surfaces of the pistons and their<br />

bores in the cylinder body for scoring, or<br />

evidence of metal-to-metal contact. If evident,<br />

renew the complete wheel cylinder assembly.<br />

10 If the pistons and bores are in good<br />

condition, remove and discard the seals and<br />

obtain a repair kit, which will contain all the<br />

necessary renewable items. Note the correct<br />

fitted orientation of the seals to ensure correct<br />

fitment of the new seals.<br />

11 Lubricate the new piston seals with clean<br />

brake fluid, and fit them onto the pistons with<br />

their larger diameters innermost.<br />

12 Insert the spring in the cylinder,<br />

13 Insert the pistons into the cylinder bores<br />

using a twisting motion.<br />

14 Fit the dust seals, and check that the<br />

pistons can move freely in their bores.<br />

Refitting<br />

15 Ensure that the backplate and wheel<br />

cylinder mating surfaces are clean, then<br />

spread the brake shoes and manoeuvre the<br />

wheel cylinder into position.<br />

16 Insert the brake pipe, and screw in the<br />

union nut two or three turns to ensure that the<br />

thread has started.<br />

17 Insert the two wheel cylinder retaining<br />

bolts, and tighten them to the specified torque.<br />

Now fully tighten the brake pipe union nut.<br />

18 Remove the clamp from the flexible brake<br />

hose, or the polythene from the master<br />

cylinder reservoir (as applicable). ’