Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Engine in-car repair procedures 2A.3<br />

in the form of a small cut-out , however if the<br />

terminal is not marked, follow the HT lead<br />

from the No 1 cylinder spark plug back to the<br />

distributor cap (No 1 cylinder is at the timing<br />

belt end of the engine) and using chalk or a<br />

pen (not a pencil, as the graphite will conduct<br />

electricity), place a mark on the distributor<br />

body directly under the terminal.<br />

10 Remove the distributor cap, as described<br />

in Chapter 5B<br />

11 Disconnect the HT leads from the spark<br />

plugs, noting their order of connection.<br />

12 To bring any piston up to TDC, it will be<br />

necessary to rotate the crankshaft manually.<br />

This can be done by using a wrench and<br />

socket on the bolt that retains the crankshaft<br />

pulley (refer to the following sub-Section for<br />

more detail).<br />

13 Rotate the crankshaft in its normal<br />

direction of rotation until the distributor rotor<br />

arm electrode begins to approach the No 1<br />

terminal marking made on the distributor<br />

Remove all four spark plugs;<br />

the lack of cylinder<br />

compression will make the<br />

engine easier to turn; refer<br />

to Chapter 1 for details.<br />

14 Carry out the following operations:<br />

a) Refer to Chapter 4A or B (as applicable)<br />

and remove the air cleaner assembly, to<br />

improve access.<br />

b) Refer to Chapter 1 and remove the<br />

auxiliary drivebelt.<br />

15 Prise open the clips and lift off the upper<br />

section of the outer timing belt cover to<br />

expose the timing belt sprockets beneath.<br />

Where applicable, remove the dipstick tube<br />

and engine earth lead, if they are secured to<br />

the timing belt cover.<br />

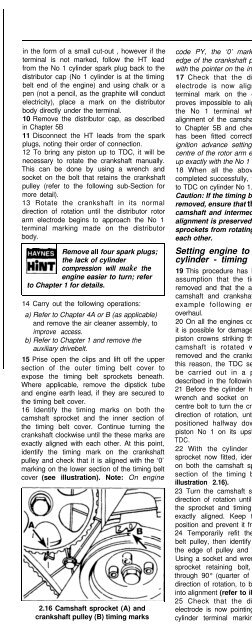

16 Identify the timing marks on both the<br />

camshaft sprocket and the inner section of<br />

the timing belt cover. Continue turning the<br />

crankshaft clockwise until the these marks are<br />

exactly aligned with each other. At this point,<br />

identify the timing mark on the crankshaft<br />

pulley and check that it is aligned with the ‘0’<br />

marking on the lower section of the timing belt<br />

cover (see illustration). Note: On engine<br />

2.16 Camshaft sprocket (A) and<br />

crankshaft pulley (B) timing marks<br />

code PY, the ‘0’ marking stamped on the<br />

edge of the crankshaft pulley must be aligned<br />

with the pointer on the inner timing be/t cover.<br />

17 Check that the distributor rotor arm<br />

electrode is now aligned with the No 1<br />

terminal mark on the distributor body. If it<br />

proves impossible to align the rotor arm with<br />

the No 1 terminal whilst maintaining the<br />

alignment of the camshaft timing marks, refer<br />

to Chapter 5B and check that the distributor<br />

has been fitted correctly. Note: The basic<br />

ignition advance setting may mean that the<br />

centre of the rotor arm electrode does not line<br />

up exactly with the No 1 terminal marking<br />

18 When all the above steps have been<br />

completed successfully, the engine will be set<br />

to TDC on cylinder No 1.<br />

Caution: If the timing belt is to be<br />

removed, ensure that the crankshaft,<br />

camshaft and intermediate shaft<br />

alignment is preserved by preventing the<br />

sprockets from rotating with respect to<br />

each other.<br />

Setting engine to TDC on No 1<br />

cylinder - timing belt removed<br />

19 This procedure has been written with the<br />

assumption that the timing belt has been<br />

removed and that the alignment between the<br />

camshaft and crankshaft has been lost, for<br />

example following engine removal and<br />

overhaul.<br />

20 On all the engines covered in this manual,<br />

it is possible for damage to be caused by the<br />

piston crowns striking the valve heads, if the<br />

camshaft is rotated with the timing belt<br />

removed and the crankshaft set to TDC. For<br />

this reason, the TDC setting procedure must<br />

be carried out in a particular order, as<br />

described in the following paragraphs.<br />

21 Before the cylinder head is refitted, use a<br />

wrench and socket on the crankshaft pulley<br />

centre bolt to turn the crankshaft in its normal<br />

direction of rotation, until all four pistons are<br />

positioned halfway down their bores, with<br />

piston No 1 on its upstroke -i.e. 90° before<br />

TDC.<br />

22 With the cylinder head and camshaft<br />

sprocket now fitted, identify the timing marks<br />

on both the camshaft sprocket and the inner<br />

section of the timing belt cover (refer to<br />

illustration 2.16).<br />

23 Turn the camshaft sprocket in its normal<br />

direction of rotation until the timing marks on<br />

the sprocket and timing belt inner cover are<br />

exactly aligned. Keep the camshaft in this<br />

position and prevent it from moving.<br />

24 Temporarily refit the crankshaft auxiliary<br />

belt pulley, then identify the timing marks on<br />

the edge of pulley and the timing belt cover.<br />

Using a socket and wrench on the crankshaft<br />

sprocket retaining bolt, turn the crankshaft<br />

through 90° (quarter of a turn) in its normal<br />

direction of rotation, to bring the timing marks<br />

into alignment (refer to illustration 2.16)<br />

25 Check that the distributor rotor arm<br />

electrode is now pointing roughly at the No1<br />

cylinder terminal marking on the distributor<br />

body. If this is not the case, refer to Chapter<br />

5B and check that the distributor has been<br />

fitted correctly. Note: The basic ignition<br />

advance setting may mean that the centre of<br />

the rotor arm electrode does not line up<br />

exactly with the No 1 terminal marking.<br />

26 When all the above steps have been<br />

completed successfully, the engine will be set<br />

at TDC on cylinder No 1. The timing belt can<br />

now be fitted as described in Section 4.<br />

Caution: Until the timing belt is fitted,<br />

ensure that the crankshaft and camshaft<br />

alignment is preserved by preventing the<br />

sprockets from rotating with respect to<br />

each other.<br />

1 When engine performance is down, or if<br />

misfiring occurs which cannot be attributed to<br />

the ignition or fuel systems, a compression<br />

test can provide diagnostic clues as to the<br />

engine’s condition. If the test is performed<br />

regularly, it can give warning of trouble before<br />

any other symptoms become apparent.<br />

2 The engine must be fully warmed-up to<br />

normal operating temperature, the battery<br />

must be fully charged, and all the spark plugs<br />

must be removed (refer to Chapter 1). The aid<br />

of an assistant will also be required.<br />

3 Disable the ignition system by<br />

disconnecting the ignition HT coil lead from<br />

the distributor cap and earthing it on the<br />

cylinder block. Use a jumper lead or similar<br />

wire to make a good connection.<br />

4 Fit a compression tester to the No 1<br />

cylinder spark plug hole - the type of tester<br />

which screws into the plug thread is<br />

preferable.<br />

5 Have an assistant hold the throttle wide<br />

open, then crank the engine on the starter<br />

motor; after one or two revolutions, the<br />

compression pressure should build up to a<br />

maximum figure, and then stabilise. Record<br />

the highest reading obtained.<br />

6 Repeat the test on the remaining cylinders,<br />

recording the pressure in each. Keep the<br />

throttle wide open.<br />

7 All cylinders should produce very similar<br />

pressures; a difference of more than 2 bars<br />

between any two cylinders indicates a fault.<br />

Note that the compression should build up<br />

quickly in a healthy engine; low compression<br />

on the first stroke, followed by graduallyincreasing<br />

pressure on successive strokes,<br />

indicates worn piston rings. A low<br />

compression reading on the first stroke, which<br />

does not build up during successive strokes,<br />

indicates leaking valves or a blown head<br />

gasket (a cracked head could also be the<br />

cause). Deposits on the undersides of the<br />

valve heads can also cause low compression.<br />

8 Refer to the Specifications section of this<br />

Chapter and compare the recorded<br />

compression figures with those stated by the