Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Braking system 9.5<br />

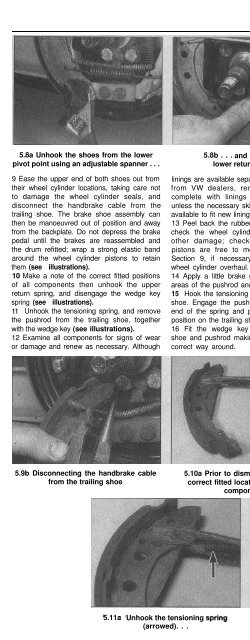

5.8a Unhook the shoes from the lower<br />

pivot point using an adjustable spanner . . .<br />

9 Ease the upper end of both shoes out from<br />

their wheel cylinder locations, taking care not<br />

to damage the wheel cylinder seals, and<br />

disconnect the handbrake cable from the<br />

trailing shoe. The brake shoe assembly can<br />

then be manoeuvred out of position and away<br />

from the backplate. Do not depress the brake<br />

pedal until the brakes are reassembled and<br />

the drum refitted; wrap a strong elastic band<br />

around the wheel cylinder pistons to retain<br />

them (see illustrations).<br />

10 Make a note of the correct fitted positions<br />

of all components then unhook the upper<br />

return spring, and disengage the wedge key<br />

spring (see illustrations).<br />

11 Unhook the tensioning spring, and remove<br />

the pushrod from the trailing shoe, together<br />

with the wedge key (see illustrations).<br />

12 Examine all components for signs of wear<br />

or damage and renew as necessary. Although<br />

5.8b . . . and remove the<br />

lower return spring<br />

linings are available separately (without shoes)<br />

from VW dealers, renewal of the shoes<br />

complete with linings is to be preferred,<br />

unless the necessary skills and equipment are<br />

available to fit new linings to the old shoes.<br />

13 Peel back the rubber protective caps, and<br />

check the wheel cylinder for fluid leaks or<br />

other damage; check that both cylinder<br />

pistons are free to move easily. Refer to<br />

Section 9, if necessary, for information on<br />

wheel cylinder overhaul.<br />

14 Apply a little brake grease to the contact<br />

areas of the pushrod and handbrake lever.<br />

15 Hook the tensioning spring into the trailing<br />

shoe. Engage the pushrod with the opposite<br />

end of the spring and pivot the pushrod into<br />

position on the trailing shoe.<br />

16 Fit the wedge key between the trailing<br />

shoe and pushrod making sure it is fitted the<br />

correct way around.<br />

5.9a Note the elastic band (arrowed)<br />

used to retain pistons<br />

17 Locate the handbrake lever on the leading<br />

shoe in the pushrod, and fit the upper return<br />

spring using a pair of pliers.<br />

18 Fit the spring to the wedge key and hook<br />

it onto the trailing shoe.<br />

19 Prior to installation, clean the backplate,<br />

and apply a thin smear of high-temperature<br />

brake grease or anti-seize compound to all<br />

those surfaces of the backplate which bear on<br />

the shoes, particularly the wheel cylinder<br />

pistons and lower pivot’ point. Do not allow<br />

the lubricant to foul the friction material.<br />

20 Remove the elastic band from the wheel<br />

cylinder and offer up the shoe assembly.<br />

21 Connect the handbrake cable to the<br />

handbrake lever and locate the top of the<br />

shoes in the wheel cylinder piston slots.<br />

22 Fit the lower return spring to the shoes,<br />

then lever the bottom of the shoes onto the<br />

bottom anchor.<br />

5.9b Disconnecting the handbrake cable<br />

from the trailing shoe<br />

5.10a Prior to dismantling, note the<br />

correct fitted location of the shoe<br />

components<br />

5.10b Wedge key and spring<br />

5.11a Unhook the tensioning<br />

(arrowed). . .<br />

5.11b . . . and remove the pushrod from<br />

the trailing shoe