Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

8.2 Driveshafts<br />

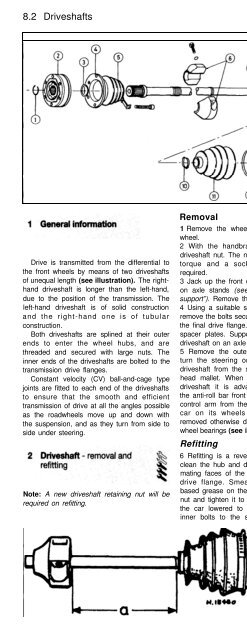

1 .1 Exploded view of the<br />

right-hand driveshaft<br />

1 Circlip<br />

2 Inner cons tan t<br />

velocity joint<br />

3 Dished washer<br />

4 Protective cap<br />

5 Rubber gaiter<br />

6 Balance weight<br />

7 Shaft<br />

8 Dished washer<br />

9 Circlip<br />

10 Clip<br />

11 Rubber gaiter<br />

12 Hose clip<br />

13 Outer constant<br />

velocity joint<br />

Drive is transmitted from the differential to<br />

the front wheels by means of two driveshafts<br />

of unequal length (see illustration). The righthand<br />

driveshaft is longer than the left-hand,<br />

due to the position of the transmission. The<br />

left-hand driveshaft is of solid construction<br />

and the right-hand one is of tubular<br />

construction.<br />

Both driveshafts are splined at their outer<br />

ends to enter the wheel hubs, and are<br />

threaded and secured with large nuts. The<br />

inner ends of the driveshafts are bolted to the<br />

transmission drive flanges.<br />

Constant velocity (CV) ball-and-cage type<br />

joints are fitted to each end of the driveshafts<br />

to ensure that the smooth and efficient<br />

transmission of drive at all the angles possible<br />

as the roadwheels move up and down with<br />

the suspension, and as they turn from side to<br />

side under steering.<br />

Note: A new driveshaft retaining nut will be<br />

required on refitting.<br />

Removal<br />

1 Remove the wheel trim from the relevant<br />

wheel.<br />

2 With the handbrake applied loosen the<br />

driveshaft nut. The nut is tightened to a high<br />

torque and a socket extension may be<br />

required.<br />

3 Jack up the front of the car and support it<br />

on axle stands (see “Jacking and vehicle<br />

support”). Remove the roadwheel.<br />

4 Using a suitable splined key, unscrew and<br />

remove the bolts securing the inner CV joint to<br />

the final drive flange. Note the location of the<br />

spacer plates. Support the inner end of the<br />

driveshaft on an axle stand.<br />

5 Remove the outer nut and washer, then<br />

turn the steering on full lock and tap the<br />

driveshaft from the splined hub using a soft<br />

head mallet. When removing the right-hand<br />

driveshaft it is advantageous to disconnect<br />

the anti-roll bar front mountings and the track<br />

control arm from the strut. Do not move the<br />

car on its wheels with either driveshaft<br />

removed otherwise damage may occur to the<br />

wheel bearings (see illustration).<br />

Refitting<br />

6 Refitting is a reversal of removal, but first<br />

clean the hub and driveshaft splines and the<br />

mating faces of the inner CV joint and final<br />

drive flange. Smear a little molybdenum<br />

based grease on the splines. Fit a new outer<br />

nut and tighten it to the specified torque with<br />

the car lowered to the ground. Tighten the<br />

inner bolts to the specified torque. On the<br />

2.5 The driveshaft inner joint<br />

2.6a Fitting the driveshaft to the final drive<br />

flange<br />

right-hand driveshaft make sure that the<br />

balance weight is located with its conical side<br />

facing the gearbox and the opposite side in<br />

the groove on the driveshaft. Where there is<br />

no groove, locate it on the point mark at the<br />

dimension shown (see illustrations).<br />

2.6b Location of the balance weight on<br />

the right-hand driveshaft<br />

Dimension a = 151.0 mm