Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Driveshafts 8.3<br />

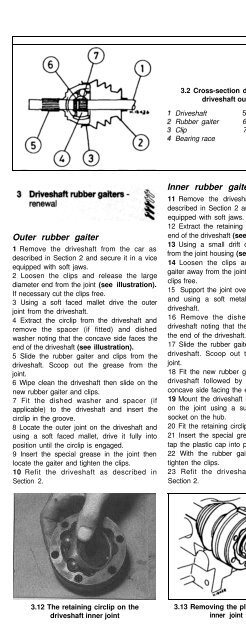

3.2 Cross-section diagram of the<br />

driveshaft outer joint<br />

Driveshaft<br />

Rubber gaiter<br />

Clip<br />

Bearing race<br />

5 Splined shaft<br />

6 Distance washer<br />

7 Dished washer<br />

Outer rubber gaiter<br />

1 Remove the driveshaft from the car as<br />

described in Section 2 and secure it in a vice<br />

equipped with soft jaws.<br />

2 Loosen the clips and release the large<br />

diameter end from the joint (see illustration).<br />

If necessary cut the clips free.<br />

3 Using a soft faced mallet drive the outer<br />

joint from the driveshaft.<br />

4 Extract the circlip from the driveshaft and<br />

remove the spacer (if fitted) and dished<br />

washer noting that the concave side faces the<br />

end of the driveshaft (see illustration).<br />

5 Slide the rubber gaiter and clips from the<br />

driveshaft. Scoop out the grease from the<br />

joint.<br />

6 Wipe clean the driveshaft then slide on the<br />

new rubber gaiter and clips.<br />

7 Fit the dished washer and spacer (if<br />

applicable) to the driveshaft and insert the<br />

circlip in the groove.<br />

8 Locate the outer joint on the driveshaft and<br />

using a soft faced mallet, drive it fully into<br />

position until the circlip is engaged.<br />

9 Insert the special grease in the joint then<br />

locate the gaiter and tighten the clips.<br />

10 Refit the driveshaft as described in<br />

Section 2.<br />

Inner rubber gaiter<br />

11 Remove the driveshaft from the car as<br />

described in Section 2 and secure it in a vice<br />

equipped with soft jaws.<br />

12 Extract the retaining circlip from the inner<br />

end of the driveshaft (see illustration).<br />

13 Using a small drift drive the plastic cap<br />

from the joint housing (see illustration).<br />

14 Loosen the clips and slide the rubber<br />

gaiter away from the joint. If necessary cut the<br />

clips free.<br />

15 Support the joint over the jaws of the vice<br />

and using a soft metal drift, drive out the<br />

driveshaft.<br />

16 Remove the dished washer from the<br />

driveshaft noting that the concave side faces<br />

the end of the driveshaft.<br />

17 Slide the rubber gaiter and clips from the<br />

driveshaft. Scoop out the grease from the<br />

joint.<br />

18 Fit the new rubber gaiter and clips to the<br />

driveshaft followed by the dished washer,<br />

concave side facing the end of the driveshaft.<br />

19 Mount the driveshaft in the vice then drive<br />

on the joint using a suitable metal tube or<br />

socket on the hub.<br />

20 Fit the retaining circlip in its groove.<br />

21 Insert the special grease in the joint then<br />

tap the plastic cap into position.<br />

22 With the rubber gaiter correctly located,<br />

tighten the clips.<br />

23 Refit the driveshaft as described in<br />

Section 2.<br />

Checking<br />

1 If any of the checks described in Chapter 1<br />

reveal wear in any driveshaft joint, first remove<br />

the roadwheel trims and check that the<br />

driveshaft retaining nuts are tight.<br />

2 Road test the vehicle, and listen for a metallic<br />

clicking from the front as the vehicle is driven<br />

slowly in a circle on full lock. If evident, this<br />

indicates wear in the outer constant velocity<br />

joint(s). This means that the joint(s) must be<br />

renewed; reconditioning is not possible.<br />

3 If vibration, consistent with road speed, is<br />

felt through the car when accelerating, there is<br />

a possibility of wear in the inner constant<br />

velocity joint(s).<br />

4 The procedure for removing or renewing<br />

the joints is described in Section 3, however if<br />

necessary the joints may be dismantled as<br />

follows for examination or for cleaning where<br />

the gaiters have broken and the joints have<br />

been contaminated with dirt or water.<br />

Cleaning<br />

Outer joint<br />

5 With the joint removed as described in<br />

Section 3, mark the hub in relation to the cage<br />

and joint housing.<br />

6 Swivel the hub and cage and remove the<br />

balls one at a time.<br />

3.12 The retaining circlip on the 3.13 Removing the plastic cap from the<br />

driveshaft inner joint<br />

inner joint housing<br />

4.7 Removing the cage and hub from the<br />

outer joint housing<br />

Arrow shows rectangular aperture