Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Manual transmission 7.3<br />

removal, refitting and<br />

adjustment<br />

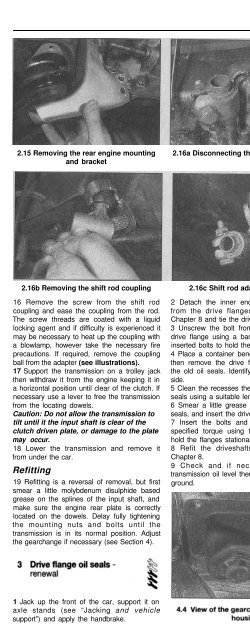

2.15 Removing the rear engine mounting<br />

and bracket<br />

2.16a Disconnecting the shift rod coupling<br />

2.16b Removing the shift rod coupling 2.16c Shift rod adapter and bush<br />

16 Remove the screw from the shift rod<br />

coupling and ease the coupling from the rod.<br />

The screw threads are coated with a liquid<br />

locking agent and if difficulty is experienced it<br />

may be necessary to heat up the coupling with<br />

a blowlamp, however take the necessary fire<br />

precautions. If required, remove the coupling<br />

ball from the adapter (see illustrations).<br />

17 Support the transmission on a trolley jack<br />

then withdraw it from the engine keeping it in<br />

a horizontal position until clear of the clutch. If<br />

necessary use a lever to free the transmission<br />

from the locating dowels.<br />

Caution: Do not allow the transmission to<br />

tilt until it the input shaft is clear of the<br />

clutch driven plate, or damage to the plate<br />

may occur.<br />

18 Lower the transmission and remove it<br />

from under the car.<br />

Refitting<br />

19 Refitting is a reversal of removal, but first<br />

smear a little molybdenum disulphide based<br />

grease on the splines of the input shaft, and<br />

make sure the engine rear plate is correctly<br />

located on the dowels. Delay fully tightening<br />

the mounting nuts and bolts until the<br />

transmission is in its normal position. Adjust<br />

the gearchange if necessary (see Section 4).<br />

2 Detach the inner ends of the driveshafts<br />

from the drive flanges with reference to<br />

Chapter 8 and tie the driveshafts to one side.<br />

3 Unscrew the bolt from the centre of each<br />

drive flange using a bar and two temporarily<br />

inserted bolts to hold the flange stationary.<br />

4 Place a container beneath the transmission<br />

then remove the drive flanges and lever out<br />

the old oil seals. Identify the flanges side for<br />

side.<br />

5 Clean the recesses then drive in the new oil<br />

seals using a suitable length of metal tubing.<br />

6 Smear a little grease on the lips of the oil<br />

seals, and insert the drive flanges.<br />

7 Insert the bolts and tighten them to the<br />

specified torque using the bar and bolts to<br />

hold the flanges stationary.<br />

8 Refit the driveshafts with reference to<br />

Chapter 8.<br />

9 Check and if necessary top-up the<br />

transmission oil level then lower the car to the<br />

ground.<br />

Removal<br />

1 Jack up the front of the car and support on<br />

axle stands (see “Jacking and vehicle<br />

support”). Apply the handbrake.<br />

2 With neutral selected, mark the shift rod<br />

and coupling in relation to each other, then<br />

unscrew the coupling clamp and pull out the<br />

shift rod.<br />

3 Working inside the car unscrew the gear<br />

knob and remove the gaiter.<br />

4 Unscrew the nuts from the ball housing<br />

stop plate, and withdraw the complete<br />

gearchange mechanism upwards into the car<br />

(see illustration). Recover the spacers.<br />

5 Dismantle the mechanism as necessary<br />

and examine the components for wear and<br />

damage. Renew those showing signs of wear<br />

or deterioration. Note that the selector rod<br />

bush is in two parts, and both parts are<br />

destroyed when removing the mechanism.<br />

When fitting the new bush, ensure that the<br />

two plastic cups are not pushed apart.<br />

Refitting<br />

6 Lubricate the joints and bearing surfaces<br />

with high-melting-point grease then refit using<br />

a reversal of the removal procedure. If a new<br />

coupling has been fitted it will be necessary to<br />

adjust the coupling position - this is best<br />

carried out by a VW dealer, as a specially<br />

shaped template is required, but if necessary<br />

the method described in the following sub-<br />

Section can be used in an emergency.<br />

Adjustment<br />

7 With the car raised and supported on axle<br />

stands (see “Jacking and vehicle support”),<br />

loosen the shift rod clamp bolt.<br />

8 Have an assistant position the gear lever as<br />

shown (see illustration). Use a twist drill for<br />

dimension (a), and align the lever so that the<br />

reverse gear catch is exactly opposite the<br />

recess in the housing.<br />

9 With the transmission still in neutral, tighten 7<br />

the clamp bolt.<br />

10 Check that all gears can be selected<br />

easily.<br />

1 Jack up the front of the car, support it on<br />

axle stands (see “Jacking and vehicle<br />

support”) and apply the handbrake.