Contents - Volkspage

Contents - Volkspage

Contents - Volkspage

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

20 000 mile service 1.11<br />

15.6 Checking the<br />

auxiliary drive belt tension<br />

assess the amount of deflection that can be<br />

caused (see illustration). Compare this<br />

measurement with that listed in the Specifications.<br />

If necessary, refer to the relevant sub-<br />

Section and correctly tension the belt.<br />

Tensioning<br />

All models except G40<br />

7 Slacken the alternator mounting screws,<br />

until the alternator can be moved by hand.<br />

6 Working underneath the alternator, slacken<br />

the tensioning strut pivot mountings. Slacken<br />

the tensioner nut lockscrew by one turn (see<br />

illustration).<br />

9 Tighten the tensioning nut to the specified<br />

‘initial’ torque - this sets the belt tension - then<br />

hold the nut in this position and tighten the<br />

tensioning nut lockscrew to the specified<br />

torque. Note: The tensioning nut ‘initial’<br />

torque figure differs for new and old belts -<br />

see Specifications for details<br />

10 Re-tighten the alternator and tensioning<br />

strut mounting screws to the specified torque,<br />

then start the engine and run it for about 5<br />

minutes, to allow the belt to settle.<br />

11 Stop the engine, then re-tension the Veebelt,<br />

as described in paragraphs 8 to 10, but<br />

this time tighten the tensioning nut to the<br />

‘final’ torque figure specified.<br />

G40 models with single or twin<br />

auxiliary Vee-belts<br />

12 The belt tension is set by rotating the<br />

G-charger on its mountings, as follows:<br />

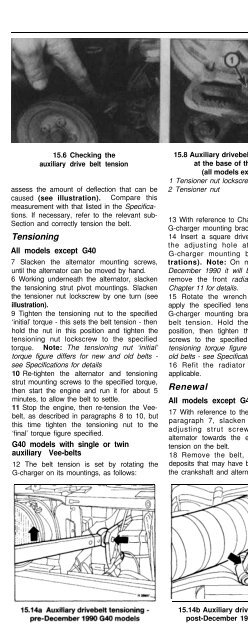

15.8 Auxiliary drivebelt tensioning strut,<br />

at the base of the alternator<br />

(all models except G40)<br />

1 Tensioner nut lockscrew<br />

2 Tensioner nut<br />

13 With reference to Chapter 4B, slacken the<br />

G-charger mounting bracket screws.<br />

14 Insert a square drive torque wrench into<br />

the adjusting hole at the edge of the<br />

G-charger mounting bracket (see illustrations).<br />

Note: On mode/s built before<br />

December 1990 it will be necessary to first<br />

remove the front radiator grille - refer to<br />

Chapter 11 for details.<br />

15 Rotate the wrench anti-clockwise and<br />

apply the specified tensioning torque to the<br />

G-charger mounting bracket - this sets the<br />

belt tension. Hold the G-charger in this<br />

position, then tighten the mounting bracket<br />

screws to the specified torque. Note: The<br />

tensioning torque figure differs for new and<br />

old belts - see Specifications for details.<br />

16 Refit the radiator front grille, where<br />

applicable.<br />

Renewal<br />

All models except G40<br />

17 With reference to the information given in<br />

paragraph 7, slacken the alternator and<br />

adjusting strut screws, then pivot the<br />

alternator towards the engine to relieve the<br />

tension on the belt.<br />

18 Remove the belt, then clean off any<br />

deposits that may have built up in the ‘vee’ of<br />

the crankshaft and alternator pulleys.<br />

19 Fit the new belt to the crankshaft and<br />

alternator pulleys, then refer to the relevant<br />

sub-Section and adjust the belt tension.<br />

G40 models with single or twin<br />

auxiliary V-belts<br />

20 With reference to the information given in<br />

paragraph 13, slacken the mounting bracket<br />

screws, then allow the G-charger to pivot<br />

down towards the engine to relieve the<br />

tension on the belt(s).<br />

21 Lift the off the belt(s), then clean off any<br />

deposits that may have built up in the ‘vee’ of<br />

the crankshaft, alternator and G-charger<br />

pulleys.<br />

22 Fit the new belt over the pulleys, then<br />

refer to the relevant sub-Section and adjust<br />

the belt tension.<br />

1 The correct functioning of the spark plugs is<br />

vital for the correct running and efficiency of<br />

the engine. It is essential that the plugs fitted<br />

are appropriate for the engine (a suitable type<br />

is specified at the beginning of this Chapter). If<br />

this type is used and the engine is in good<br />

condition, the spark plugs should not need<br />

attention between scheduled replacement<br />

intervals. Spark plug cleaning is rarely<br />

necessary, and should not be attempted unless<br />

specialised equipment is available, as damage<br />

can easily be caused to the electrodes.<br />

2 If the marks on the original-equipment spark<br />

plug (HT) leads cannot be seen, mark the leads<br />

“1” to “4”, to correspond to the cylinder the<br />

lead serves (No 1 cylinder is at the timing belt<br />

end of the engine). Pull the leads from the<br />

plugs by gripping the end fitting, not the lead,<br />

otherwise the internal lead connection may be<br />

fractured (see illustration).<br />

3 It is advisable to remove any dirt from the<br />

spark plug recesses using a clean brush or<br />

compressed air before removing the plugs, to<br />

prevent dirt dropping into the cylinders (see<br />

illustration). Note: On engine codes AAU,<br />

AAV it will be necessary to remove the air<br />

cleaner housing to gain access to the plugs.<br />

15.14b Auxiliary drivebelt tensioning -<br />

post-December 1990 G40 models<br />

16.2 Pull the leads from the plugs by<br />

gripping the end fitting