- Page 1 and 2: 1 Your contact at Siteco: Name : De

- Page 3 and 4: 3 “Coming together is the start,

- Page 5 and 6: 5 about us Uplights, desk-top and w

- Page 7 and 8: 7 about us 1 2 3 4 5 6 7 8 However,

- Page 9 and 10: 9 about us 1 2 3 4 5 6 7 8 Second,

- Page 11 and 12: 11 about us Whether used as desk-to

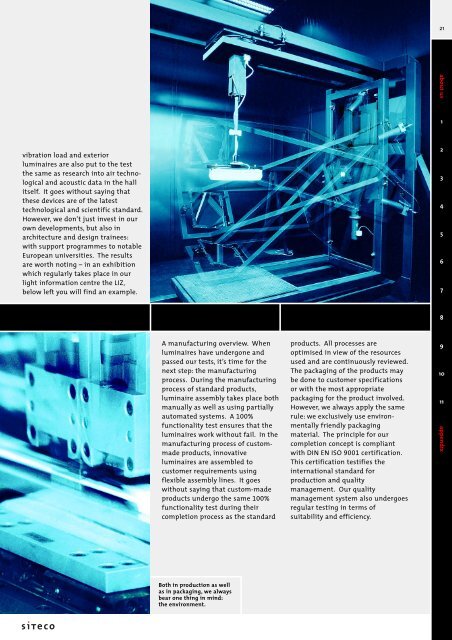

- Page 13 and 14: 13 about us 1 2 3 4 5 6 7 8 Siteco

- Page 15 and 16: 15 Downlights for all occasions: th

- Page 17 and 18: 17 about us 1 2 3 4 The starry sky

- Page 19: 19 about us 1 2 3 4 5 6 As in 1001

- Page 23 and 24: 23 about us 1 2 3 4 5 6 7 8 Lightin

- Page 25 and 26: 25 Lighting refurbishment in the of

- Page 27 and 28: 27 about us 1 2 3 4 5 6 7 8 9 10 11

- Page 29 and 30: 29 Welcome to Siteco. about us 1 2

- Page 31 and 32: 31 shopping public sports about us

- Page 33 and 34: Uplights, desktop and wall luminair

- Page 35 and 36: Uplights, desktop and wall luminair

- Page 37 and 38: Uplights and wall luminaires, Wave

- Page 39 and 40: Wave desktop luminaires 7 with ELDA

- Page 41 and 42: Mobile lighting system in 3 version

- Page 43 and 44: Mobile lighting system in 2 version

- Page 45 and 46: Mobile lighting systems, uplights,

- Page 47 and 48: 15 1

- Page 49 and 50: Downlights 1 2 Siteco Lunis_S 2/4 N

- Page 51 and 52: Downlights 3 2 Surface mounted down

- Page 53 and 54: Surface mounted downlights Lunis_S

- Page 55 and 56: New design high value surface mount

- Page 57 and 58: Recessed downlights Lunis_E 9 Lunis

- Page 59 and 60: Recessed downlights for premium ins

- Page 61 and 62: Recessed downlights for premium ins

- Page 63 and 64: Recessed downlights for premium ins

- Page 65 and 66: Recessed downlights for premium ins

- Page 67 and 68: Lunis_E 19 Optical and decorative a

- Page 69 and 70: Recessed downlights Lunis® 21 On c

- Page 71 and 72:

Recessed downlights for compact flu

- Page 73 and 74:

Recessed downlights for compact flu

- Page 75 and 76:

] Recessed downlights for compact f

- Page 77 and 78:

Recessed downlights for compact flu

- Page 79 and 80:

Recessed downlights for compact flu

- Page 81 and 82:

Siteco Lunis® 33 Optical and decor

- Page 83 and 84:

Recessed downlights HIGHLIGHT 35 2

- Page 85 and 86:

Recessed downlights with advanced l

- Page 87 and 88:

Recessed downlights with advanced l

- Page 89 and 90:

Recessed downlights with advanced l

- Page 91 and 92:

Recessed downlights with advanced l

- Page 93 and 94:

Downlights 45 Mounting Accessories

- Page 95 and 96:

Downlights 47 Electrical accessorie

- Page 97 and 98:

Downlights 49 Dimensions 5LR 514 5L

- Page 99 and 100:

Downlights 51 2

- Page 101 and 102:

Secondary systems 1 SiLUNA Secondar

- Page 103 and 104:

SiLUNA secondary surface and recess

- Page 105 and 106:

Secondary surface luminaires, SiLUN

- Page 107 and 108:

Secondary recessed luminaires, SiLU

- Page 109 and 110:

Recessed luminaires, SiLUNA 9 Overv

- Page 111 and 112:

SiLUNA secondary surface and recess

- Page 113 and 114:

Secondary reflector systems 13 3 Sy

- Page 115 and 116:

Secondary reflector system 15 SiNAR

- Page 117 and 118:

Secondary reflector system 17 SiSTA

- Page 119 and 120:

Secondary reflector system 19 SiCOM

- Page 121 and 122:

Secondary reflector system 21 SiCOM

- Page 123 and 124:

Secondary reflector system 23 Paral

- Page 125 and 126:

Secondary reflector system 25 5NW 1

- Page 127 and 128:

Secondary reflector system 27 SiSTA

- Page 129 and 130:

Secondary reflector system 29 5NW 1

- Page 131 and 132:

Secondary reflector system 31 5NW 1

- Page 133 and 134:

0 Secondary reflector system 33 Dim

- Page 135 and 136:

Secondary Reflector System 35 Dimen

- Page 137 and 138:

Secondary Reflector System 37 Dimen

- Page 139 and 140:

1 SiTECO Orbiter 4/4 Wave 4/6 SiFOR

- Page 141 and 142:

Pendant luminaires, SiTECO Orbiter

- Page 143 and 144:

Pendant luminaires, SiTECO Orbiter

- Page 145 and 146:

Pendant luminaires, Wave 7 ELDACON

- Page 147 and 148:

Pendant luminaires, SiTECO Orbiter

- Page 149 and 150:

Pendant luminaires, SiFORM for indi

- Page 151 and 152:

Pendant luminaires, SiFORM for cont

- Page 153 and 154:

Pendant luminaires, SiFORM for indi

- Page 155 and 156:

Pendant luminaires, SiFORM for indi

- Page 157 and 158:

Pendant luminaires, SiFORM for indi

- Page 159 and 160:

Pendant luminaires, SiFORM for indi

- Page 161 and 162:

Pendant luminaires, SiFORM for indi

- Page 163 and 164:

Pendant luminaires, SiFORM for indi

- Page 165 and 166:

Pendant luminaires, SiFORM for indi

- Page 167 and 168:

Pendant luminaire SiFORM 29 Orderin

- Page 169 and 170:

Pendant luminaire SiFORM 31 Special

- Page 171 and 172:

Pendant luminaire SiFORM 33 Dimensi

- Page 173 and 174:

Surface and pendant luminaires Site

- Page 175 and 176:

Surface and pendant luminaires, Sit

- Page 177 and 178:

Surface and pendant luminaires, Sit

- Page 179 and 180:

Surface and pendant luminaires, Sit

- Page 181 and 182:

Surface and pendant luminaires, Sit

- Page 183 and 184:

Surface and pendant luminaires, Sit

- Page 185 and 186:

Surface and pendant luminaires, Sit

- Page 187 and 188:

Surface and pendant luminaires, Sit

- Page 189 and 190:

Surface and pendant luminaires Site

- Page 191 and 192:

Surface and pendant luminaires, Sit

- Page 193 and 194:

Surface and pendant luminaires, Sit

- Page 195 and 196:

Surface and pendant luminaires, Sit

- Page 197 and 198:

Surface and pendant luminaires, Sit

- Page 199 and 200:

Surface and pendant luminaires, Sit

- Page 201 and 202:

Surface and pendant luminaires, Sit

- Page 203 and 204:

Surface and pendant luminaires, Sit

- Page 205 and 206:

Surface and pendant luminaires, Sit

- Page 207 and 208:

Surface and pendant luminaires, Sit

- Page 209 and 210:

Surface and pendant luminaires, Sit

- Page 211 and 212:

Surface and pendant luminaires, Sit

- Page 213 and 214:

Surface and pendant luminaires, Sit

- Page 215 and 216:

Surface and pendant luminaires, Sit

- Page 217 and 218:

Surface and pendant luminaires, Sit

- Page 219 and 220:

Surface and pendant luminaires, Sit

- Page 221 and 222:

Surface and pendant luminaires, Sit

- Page 223 and 224:

Surface and pendant luminaires, Sit

- Page 225 and 226:

Surface and pendant luminaires, Sit

- Page 227 and 228:

Surface and pendant luminaires, Sit

- Page 229 and 230:

Surface and pendant luminaires, Sit

- Page 231 and 232:

Surface and pendant luminaires, Sit

- Page 233 and 234:

Surface ceiling washer 95 4 SiLING

- Page 235 and 236:

Surface luminaire, SiLING 97 Asymme

- Page 237 and 238:

Surface luminaire, Ceilingwasher 99

- Page 239 and 240:

Surface luminaire, Ceilingwasher 10

- Page 241 and 242:

Recessed luminaires 1 5 Recessed lu

- Page 243 and 244:

Recessed luminaires 3 5 With the Si

- Page 245 and 246:

Recessed luminaires 5 Recessed lumi

- Page 247 and 248:

Recessed luminaires Siteco LF7 7 5

- Page 249 and 250:

Refurbishment luminaire, Siteco LF7

- Page 251 and 252:

Refurbishment luminaire, Siteco LF7

- Page 253 and 254:

Refurbishment luminaire, Siteco LF7

- Page 255 and 256:

Refurbishment luminaire, Siteco LF7

- Page 257 and 258:

Siteco LF7 17 Dimensions Siteco LF7

- Page 259 and 260:

Siteco LF7 19 Dimensions Three lamp

- Page 261 and 262:

Recessed luminaires, Siteco LF1 21

- Page 263 and 264:

Recessed luminaires, Siteco LF1 23

- Page 265 and 266:

Recessed luminaires, Siteco LF1 25

- Page 267 and 268:

Recessed luminaires, Siteco LF1 27

- Page 269 and 270:

Recessed luminaires, Siteco LF1 29

- Page 271 and 272:

Recessed luminaires, Siteco LF1 31

- Page 273 and 274:

Recessed luminaires, Siteco LF1 33

- Page 275 and 276:

Recessed luminaires, Siteco LF1 35

- Page 277 and 278:

Recessed luminaires, Siteco LP1/LP7

- Page 279 and 280:

Recessed luminaires, Siteco LP1 39

- Page 281 and 282:

Recessed luminaires, Siteco LP1 41

- Page 283 and 284:

Recessed luminaires, Siteco LP1/LP7

- Page 285 and 286:

Recessed luminaires, Siteco LQ1 45

- Page 287 and 288:

Recessed luminaires, Siteco LP1 47

- Page 289 and 290:

Recessed luminaires, Siteco LP1/LP7

- Page 291 and 292:

Recessed luminaires, Siteco LP1/LP7

- Page 293 and 294:

Recessed luminaires, Siteco LP1/LP7

- Page 295 and 296:

Recessed ceiling washer 55 5 Ceilin

- Page 297 and 298:

Recessed ceiling washer 57 Matt fin

- Page 299 and 300:

Recessed ceiling washer 59 Dimensio

- Page 301 and 302:

Air-handling recessed luminaires, S

- Page 303 and 304:

Air handling recessed luminiares 3

- Page 305 and 306:

Air-handling recessed luminaires, S

- Page 307 and 308:

Air-handling recessed luminaires, S

- Page 309 and 310:

Air-handling recessed luminaires, S

- Page 311 and 312:

Air-handling recessed luminaires, S

- Page 313 and 314:

Air-handling recessed luminaires, S

- Page 315 and 316:

Trunking systems 1 Hexal-a and Hexa

- Page 317 and 318:

Hexal trunking systems 3 7 Hexal sy

- Page 319 and 320:

Hexal-a and Hexal-s trunking system

- Page 321 and 322:

Hexal-a trunking system for T5 fluo

- Page 323 and 324:

Hexal-a trunking system for T5 fluo

- Page 325 and 326:

Hexal-a trunking system for T8 fluo

- Page 327 and 328:

Hexal-a trunking system for T8 fluo

- Page 329 and 330:

Hexal-a trunking system for T8 fluo

- Page 331 and 332:

Hexal-a trunking system for T8 fluo

- Page 333 and 334:

Hexal-a trunking system for T8 fluo

- Page 335 and 336:

Hexal-a and Hexal-s trunking system

- Page 337 and 338:

Hexal-a and Hexal-s trunking system

- Page 339 and 340:

DUS IP20 trunking system 25 Overvie

- Page 341 and 342:

DUS IP20 trunking system 27 Overvie

- Page 343 and 344:

DUS IP20 trunking system 29 Trunkin

- Page 345 and 346:

DUS IP20 trunking system 31 Battens

- Page 347 and 348:

DUS IP20 trunking system 33 Emergen

- Page 349 and 350:

DUS IP20 trunking system 35 Trough

- Page 351 and 352:

DUS IP20 trunking system 37 Perfora

- Page 353 and 354:

DUS IP20 trunking system 39 Alumini

- Page 355 and 356:

DUS IP20 trunking system 41 Alumini

- Page 357 and 358:

DUS IP20 trunking system 43 Optical

- Page 359 and 360:

DUS IP20 trunking system 45 Optical

- Page 361 and 362:

DUS IP20 trunking system 47 Accesso

- Page 363 and 364:

DUS IP20 trunking system 49 Mountin

- Page 365 and 366:

DUS IP20 trunking system 51 Trunkin

- Page 367 and 368:

DUS IP20 trunking system 53 Dimensi

- Page 369 and 370:

Batten Luminaires 55 Batten luminai

- Page 371 and 372:

Batten luminaires for T5 and T8 lam

- Page 373 and 374:

Batten luminaires, DUS, for T8 lamp

- Page 375 and 376:

Batten luminaires, DUS, for T8 lamp

- Page 377 and 378:

Batten luminaires, DUS, for T8 lamp

- Page 379 and 380:

Batten luminaires, DUS, for T8 lamp

- Page 381 and 382:

Special clean area luminaire IP20 6

- Page 383 and 384:

Batten luminaires 69 Dimensions H L

- Page 385 and 386:

Surface diffuser luminaires 1 Europ

- Page 387 and 388:

Surface diffuser luminaire, Europle

- Page 389 and 390:

Surface diffuser luminaire, Europle

- Page 391 and 392:

Surface diffuser luminaire, Europle

- Page 393 and 394:

Surface diffuser luminaire, Europle

- Page 395 and 396:

Surface diffuser luminaire, Europle

- Page 397 and 398:

Surface diffuser luminaires, Europl

- Page 399 and 400:

l Surface diffuser luminaires 15 Di

- Page 401 and 402:

Recessed diffuser luminaire, SiLUZE

- Page 403 and 404:

Recessed diffuser luminaire, SiLUZE

- Page 405 and 406:

Damp proof luminaires 1 Wherever th

- Page 407 and 408:

Damp proof luminaires 3 FR500 Damp

- Page 409 and 410:

Damp proof diffuser luminaire, FR50

- Page 411 and 412:

Damp proof diffuser luminaire, FR20

- Page 413 and 414:

Damp proof diffuser luminaire, FR10

- Page 415 and 416:

Damp proof diffuser luminaire, FR10

- Page 417 and 418:

Damp proof diffuser luminaires, FR5

- Page 419 and 420:

Damp proof diffuser luminaire, Mons

- Page 421 and 422:

Damp proof diffuser luminaire, Mons

- Page 423 and 424:

Damp proof diffuser luminaire, Mons

- Page 425 and 426:

Damp proof diffuser luminaire, Mons

- Page 427 and 428:

Damp proof diffuser luminaire, Mons

- Page 429 and 430:

Damp proof diffuser luminaire, SiPL

- Page 431 and 432:

Damp proof diffuser luminaire, SiPL

- Page 433 and 434:

Open lamp distribution damp-proof l

- Page 435 and 436:

Open lamp distribution damp-proof l

- Page 437 and 438:

Damp proof luminaire 33 Dimensions

- Page 439 and 440:

H Damp proof luminaire 35 Dimension

- Page 441 and 442:

Mounting rails 37 DUS trunking, gal

- Page 443 and 444:

Mounting rails 39 Mounting rail, pl

- Page 445 and 446:

High bay luminaires 1 Luminaire sys

- Page 447 and 448:

High bay luminaires 3 High bay lumi

- Page 449 and 450:

High bay luminaires 5 with paraboli

- Page 451 and 452:

High bay luminaires 7 Accessories H

- Page 453 and 454:

High bay reflector luminaires ASTER

- Page 455 and 456:

High bay reflector luminaire, ASTER

- Page 457 and 458:

High bay reflector luminaire, ASTER

- Page 459 and 460:

High bay reflector luminaire, ASTER

- Page 461 and 462:

High bay reflector luminaire, ASTER

- Page 463 and 464:

High bay reflector luminaire, ASTER

- Page 465 and 466:

High bay luminaires HS100 21 10

- Page 467 and 468:

High bay reflector luminaire, HS 10

- Page 469 and 470:

High bay luminaires, HS 100 25 with

- Page 471 and 472:

High bay reflector luminaire, HS 10

- Page 473 and 474:

37 H High bay reflector luminaire,

- Page 475 and 476:

Compact reflector luminaire 31 Comp

- Page 477 and 478:

Compact reflector luminaires 33 wit

- Page 479 and 480:

] Compact reflector luminaires, bal

- Page 481 and 482:

Floodlights, SiCOMPACT A MIDI 37 As

- Page 483 and 484:

Floodlights, SiCOMPACT A MINI 39 As

- Page 485 and 486:

Floodlights, SiCOMPACT A MINI 41 Di

- Page 487 and 488:

43 10

- Page 489 and 490:

Specific customer lighting solution

- Page 491 and 492:

Specific customer lighting solution

- Page 493 and 494:

AVION suspended luminaire 5 The des

- Page 495 and 496:

System Esline - innovation in light

- Page 497 and 498:

Wing luminaire - soft light with ai

- Page 499 and 500:

Indirect channel Luminaire with dec

- Page 501 and 502:

One luminaire - three light moods,

- Page 503 and 504:

Circ - the round, all around glare

- Page 505 and 506:

H Linear curved reflector with VDU

- Page 507 and 508:

Compact surface mounted ring lens d

- Page 509 and 510:

ENOMIS - Semi-recessed secondary lu

- Page 511 and 512:

LUMOS - a new light for the office

- Page 513 and 514:

System STREXX, the intelligent modu

- Page 515 and 516:

Ceiling Washer - asymmetrical distr

- Page 517 and 518:

Siluna VT - recessed luminaire with

- Page 519 and 520:

Daylight systems 31 General 32 Micr

- Page 521 and 522:

Daylight systems 33 The natural com

- Page 523 and 524:

Daylight systems 35 Micro sun sheil

- Page 525 and 526:

Daylight systems 37 Moveable prism

- Page 527 and 528:

Daylight systems 39 Static prism sy

- Page 529 and 530:

Appendix 1 Luminaire technical data

- Page 531 and 532:

Appendix 3 Luminaire technical data

- Page 533 and 534:

Appendix 5 Light planning Project D

- Page 535 and 536:

Appendix 7 Optical data and termino

- Page 537 and 538:

Appendix 9 Installation and operati

- Page 539 and 540:

Appendix 11 HF-Dimming with 1...10V

- Page 541 and 542:

Appendix 13 Control gear Benefits o

- Page 543 and 544:

Appendix 15 Power factor correction

- Page 545 and 546:

Appendix 17 Refurbishment Saving is

- Page 547 and 548:

Appendix 19 Icon Legend Maximum con

- Page 549 and 550:

Appendix 21 Icon Legend Lamps TC-T

- Page 551 and 552:

Appendix 23 lamp technical data Cat

- Page 553 and 554:

Appendix 25 Index O Opal diffusers

- Page 555 and 556:

Appendix 27 Code Chapter/Page Code

- Page 557 and 558:

Appendix 29 Code Chapter/Page Code

- Page 559 and 560:

Appendix 31 Code Chapter/Page Code

- Page 561 and 562:

Appendix 33 Our Manufacturing and D