- Page 1 and 2:

,0 *• DATSUN - «; fjffl rfi i Sf

- Page 3 and 4:

SECTION Gl c If DATSUN 280Z r^lODEL

- Page 5 and 6:

General Information IDENTIFICATION

- Page 7 and 8:

i General Information 1 LUBRICANT S

- Page 9 and 10:

.1ft. SECTION ET (• «I DATSUN 28

- Page 11 and 12:

Engine Tune-up v ET012 Fig. ET-7 Te

- Page 13 and 14:

CHECKING OPERATING PARTS OF DISTRIB

- Page 15 and 16:

Engine Tune-up Rubber fuel hoses in

- Page 17 and 18:

Engine Tune-up EMISSION CONTROL SYS

- Page 19 and 20:

Engine Tune-up Checking vacuum cont

- Page 21 and 22:

^ CHECKING SPARK TIMING CONTROL SYS

- Page 23 and 24:

Engine Tune-up CHECKING TRANSMISSIO

- Page 25 and 26:

Engine Tune-up 4. Supply fresh air

- Page 27 and 28:

^ 2. If voltmeter reading is not as

- Page 29 and 30:

Engine Tune-up 6. Check continuity

- Page 31 and 32:

Engine Tune-up Checking catalyzer t

- Page 33 and 34:

Engine Tune-up Note: Do not heat fl

- Page 35 and 36:

Engine Tune-up TROUBLE DIAGNOSES AN

- Page 37 and 38:

Engine Tune-up Condition Probable c

- Page 39 and 40:

Engine Tune-up Condition Probable c

- Page 41 and 42:

Engine Tune-up Condition Excessive

- Page 43 and 44:

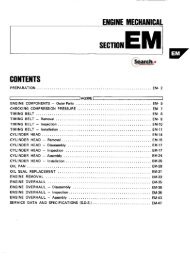

RL'#«W frs •: K?A: *- •f SECTI

- Page 45 and 46:

supported by No. 2, 3 and 4 camshaf

- Page 47 and 48:

17. Remove intake manifold and heat

- Page 49 and 50:

Engine Mechanical INSPECTION AND RE

- Page 51 and 52:

ROCKER ARM AND VALVE ROCKER PIVOT C

- Page 53 and 54:

Engine Mechanical 3. Machine cylind

- Page 55 and 56:

Engine Mechanical 1 20 (0.79) 60 (2

- Page 57 and 58:

Engine Mechanical PISTONS, PISTON P

- Page 59 and 60:

Engine Mechanical L28 Crankshaft be

- Page 61 and 62:

Engine Mechanical Connecting rod be

- Page 63 and 64:

Engine Mechanical ENGINE ASSEMBLY C

- Page 65 and 66:

Engine Mechanical 5. Install main b

- Page 67 and 68:

Fig. EM-105 Installing crankshaft p

- Page 69 and 70:

Engine Mechanical 44. Install engin

- Page 71 and 72:

Engine Mechanical SPECIFICATIONS Mo

- Page 73 and 74:

Engine Mechanical c) Connecting rod

- Page 75 and 76:

Engine Mechanical TROUBLE DfAGNOSES

- Page 77 and 78:

Engine Mechanical SPECIAL SERVICE T

- Page 79 and 80:

Engine Mechanical No. Tool number &

- Page 81 and 82:

«i">! fTC* **£' :. Si. SECTION EL

- Page 83 and 84:

Punch mark ' Oil hole EL009 Fig.EL-

- Page 85 and 86:

Engine Lubrication System SERVICE D

- Page 87 and 88:

SECTION CO '%••' DATSUN 280Z MO

- Page 89 and 90:

Cooling System COOLANT LEVEL The co

- Page 91 and 92:

INSPECTION Check Tem-coupling for o

- Page 93 and 94:

Cooling System SPECIFICATIONS Engin

- Page 95 and 96:

SERVlCt MANUAL DATSUN 280Z MODEL S3

- Page 97 and 98:

Engine Fuel ELECTRONIC FUEL INJECTI

- Page 99 and 100:

• RjaFLOW + - AIR ROW ^ VACUUM

- Page 101 and 102:

DROPPING RESISTOR (1) DROPPING RESI

- Page 103 and 104:

AIR FLOW METER THROTTLE VALVE SWITC

- Page 105 and 106:

Engine Fuel I) COLD START VALVE INC

- Page 107 and 108:

Engine Fuel © TERMINAL © TERMINAL

- Page 109 and 110:

Engine Fuel Fig. EF-20 Dropping res

- Page 111 and 112:

Engine Fuel Direction of bimetal mo

- Page 113 and 114:

Engine Fuel If a continuity test on

- Page 115 and 116:

Connector and harness continuity ch

- Page 117 and 118:

Use the same procedure as in step 9

- Page 119 and 120:

THERMOTIME SW 1 COLD START VALVE I

- Page 121 and 122:

THERMOTIME SW. "~l COLO START VALVE

- Page 123 and 124:

THERMOTIME SW i 1 COLD START WATER

- Page 125 and 126:

THERMOTIME SW i 1 COLD START WATER

- Page 127 and 128:

THERMOTIME SW i 1 COLD START VALVE

- Page 129 and 130:

THERMOTIME SW i 1 COLD START VALVE

- Page 131 and 132:

THERMOTIME SW. I 1 COLD START VALVE

- Page 133 and 134:

THERMOTIME SW i 1 COLD START VALVE

- Page 135 and 136:

Engine Fuel in oo r> ri2a!2Di^9 0 >

- Page 137 and 138:

Engine Fuel o m o p N c o i o ' J '

- Page 139 and 140:

THERMOTIME SW i 1 46 COLD START VAL

- Page 141 and 142:

THERMOTIME SW i 1 COLD START WATER

- Page 143 and 144:

THERMOTIME SW. i 1 COLC START VALVE

- Page 145 and 146:

CHECKING FUNCTIONAL PARTS 1. Contro

- Page 147 and 148:

Engine Fuel 4-1. Checking on engine

- Page 149 and 150:

Engine Fuel •0+ (J3!5 EF408 Fig.

- Page 151 and 152:

Discharge pressure check 1. Disconn

- Page 153 and 154:

4. Make sure that idle adjust screw

- Page 155 and 156:

Engine Fuel Caution: When connectin

- Page 157 and 158:

11. Fuel damper 1. Disconnect groun

- Page 159 and 160:

15. Air regulator 1. Disconnect gro

- Page 161 and 162:

SECTION EC DATSUN 280Z MODEL S30 SE

- Page 163 and 164:

Emission Control System EXHAUST EMI

- Page 165 and 166:

BOOST CONTROLLED DECELERATION DEVIC

- Page 167 and 168:

Emission Control System B.C.D.D. so

- Page 169 and 170:

TRANSMISSION CONTROLLED VACUUM ADVA

- Page 171 and 172:

Emission Control System 1 Intake ma

- Page 173 and 174:

Water temperature switch and E.G.R.

- Page 175 and 176:

Emission Control System By means of

- Page 177 and 178:

OPERATION Catalytic converter The e

- Page 179 and 180:

Emission Control System Catalyzer w

- Page 181 and 182:

Turn ignition switch to the IG posi

- Page 183 and 184:

4. If voltmeter reading is not as s

- Page 185 and 186:

Emission Control System 7. Check co

- Page 187 and 188:

Emission Control System When cataly

- Page 189 and 190:

Emission Control System Floor senso

- Page 191 and 192:

Emission Control System If test res

- Page 193 and 194:

SECTION EE DATSUN MODEL 280Z S30 SE

- Page 195 and 196:

Engine Electrical System BATTERY FR

- Page 197 and 198:

Engine Electrical System STARTING M

- Page 199 and 200:

Engine Electrical System CONSTRUCTI

- Page 201 and 202:

Engine Electrical System TERMINAL C

- Page 203 and 204:

TEST PERFORMANCE TEST Starter motor

- Page 205 and 206:

Engine Electrical System Condition

- Page 207 and 208:

Engine Electrical System ALTERNATOR

- Page 209 and 210:

ROTOR INSPECTION 1. Continuity test

- Page 211 and 212:

ALTERNATOR TEST Before conducting a

- Page 213 and 214:

Engine Electrical System MEASUREMEN

- Page 215 and 216:

ADJUSTMENT VOLTAGE REGULATOR When r

- Page 217 and 218:

Engine Electrical System TROUBLE DI

- Page 219 and 220:

Engine Electrical System DISTRIBUTO

- Page 221 and 222:

Engine Electrical System Fig. EE-64

- Page 223 and 224:

Engine Electrical System 4. Apply g

- Page 225 and 226:

Engine Electrical System Transistor

- Page 227 and 228:

Engine Electrical System EE379 Fig.

- Page 229 and 230:

Engine Electrical System Criterion:

- Page 231 and 232:

Ignition switch ©K^ BL BW 6 \ Wate

- Page 233 and 234:

Engine Electrical System ® -®- -

- Page 235 and 236:

Engine Electrical System EE387 Fig.

- Page 237 and 238:

Engine Electrical System IGNITION C

- Page 239 and 240:

Engine Electrical System SERVICE DA

- Page 241 and 242:

SERVICE MANUAL DATSUN 280Z MODEL S3

- Page 243 and 244:

12. Disconnect the following cables

- Page 245 and 246:

ENGINE MOUNTING INSULATORS Three in

- Page 247 and 248:

SERVICE MANUAL DATSUN 280Z MODEL S3

- Page 249 and 250:

( Clutch Flywheel and pressure plat

- Page 251 and 252:

Clutch 4 5 to 5.0 mm (0.18 to 0.20

- Page 253 and 254:

1. Pedal head rubber 2. Return spri

- Page 255 and 256:

Clutch SERVICE DATA AND SPECIFICATI

- Page 257 and 258:

Clutch Condition Probable cause and

- Page 259:

Clutch No. Tool number & tool name

- Page 262 and 263:

Transmission 4-SPEED TRANSMISSION (

- Page 264 and 265:

Fig. TM-7 Removing main drive beari

- Page 266 and 267:

Transmission Countershaft assembly

- Page 268 and 269:

Coat oil seal and bushing with gear

- Page 270 and 271:

7. Install mainshaft reverse gear,

- Page 272 and 273:

GENERAL SPECIFICATIONS Transmission

- Page 274 and 275:

Transmission TROUBLE DIAGNOSES AND

- Page 276 and 277:

i Transmission Tool number & tool n

- Page 278 and 279:

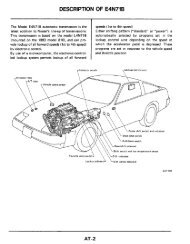

Automatic Transmission DESCRIPTION

- Page 280 and 281:

Automatic Transmission HYDRAULIC CO

- Page 282 and 283:

the space from (1) to (15) increase

- Page 284 and 285:

1st-2nd shift valve (FSV) The FSV i

- Page 286 and 287:

space from the throttle pressure (1

- Page 288 and 289:

Automatic Transmission rm AT094 1 P

- Page 290 and 291:

i Automatic Transmission "P" RANGE

- Page 292 and 293:

Automatic Transmission "R" RANGE (R

- Page 294 and 295:

Automatic Transmission "N" RANGE (N

- Page 296 and 297:

"D " RANGE (LOW GEAR) The low gear

- Page 298 and 299:

Automatic Transmission "D " RANGE (

- Page 300 and 301:

Automatic Transmission "D 3 " RANGE

- Page 302 and 303:

Automatic Transmission "D" RANGE KI

- Page 304 and 305:

"2" RANGE (2ND GEAR) In "2" range t

- Page 306 and 307:

Automatic Transmission "1 " RANGE (

- Page 308 and 309:

Automatic Transmission "1" range (2

- Page 310 and 311:

Automatic Transmission AT116 Fig. A

- Page 312 and 313:

Automatic Transmission MAJOR REPAIR

- Page 314 and 315:

Automatic Transmission AT 133 Fig.

- Page 316 and 317:

Adjustment of front end play Select

- Page 318 and 319:

3. Blow out piston by directing a j

- Page 320 and 321:

Automatic Transmission [Replace if

- Page 322 and 323:

Automatic Transmission Valve spring

- Page 324 and 325:

Automatic Transmission TROUBLE DIAG

- Page 326 and 327:

Check whether the reverse lamp and

- Page 328 and 329:

Automatic Transmission CHECKING SPE

- Page 330 and 331:

Automatic Transmission TROUBLE-SHOO

- Page 332 and 333:

Automatic Transmission Trouble A B

- Page 334 and 335:

Automatic Transmission Order Test i

- Page 336 and 337:

Low & reverse brake Brake band Auto

- Page 338 and 339:

Automatic Transmission SPECIAL SERV

- Page 340 and 341:

Automatic Transmission Tool number

- Page 342 and 343:

Propeller Shaft & Differential Carr

- Page 344 and 345:

Propeller Shaft & Differential Carr

- Page 346 and 347:

Propeller Shaft & Differential Carr

- Page 348 and 349:

Propeller Shaft & Differential Carr

- Page 350 and 351:

Propeller Shaft & Differential Carr

- Page 352 and 353:

Propeller Shaft & Differential Carr

- Page 354 and 355:

Propeller Shaft & Differential Carr

- Page 356 and 357:

Propeller Shaft & Differential Carr

- Page 358 and 359:

Propeller Shaft & Differential Carr

- Page 360 and 361:

Propeller Shaft & Differential Carr

- Page 362 and 363:

Propeller Shaft & Differential Carr

- Page 364 and 365:

Front Axle & Front Suspension DESCR

- Page 366 and 367:

8. Install hub cap. WHEEL ALIGNMENT

- Page 368 and 369:

Front Axle & Front Suspension 1 Out

- Page 370 and 371:

Front Axle & Front Suspension a) In

- Page 372 and 373:

Front Axle & Front Suspension i REM

- Page 374 and 375:

Notes: a. When tightening gland pac

- Page 376 and 377:

Front Axle & Front Suspension INSPE

- Page 378 and 379:

Front Axle & Front Suspension Coil

- Page 380 and 381:

Front Axle & Front Suspension TROUB

- Page 382 and 383:

Front Axle & Front Suspension Condi

- Page 384 and 385:

Front Axle & Front Suspension No. T

- Page 386 and 387:

Rear Axle & Rear Suspension DESCRIP

- Page 388 and 389:

Rear Axle & Rear Suspension REAR AX

- Page 390 and 391:

Rear Axle & Rear Suspension REMOVAL

- Page 392 and 393:

Rear Axle & Rear Suspension 2. Jack

- Page 394 and 395:

10. Remove link mounting rear brack

- Page 396 and 397:

Rear Axle & Rear Suspension Front d

- Page 398 and 399:

Rear Axle & Rear Suspension SPECIAL

- Page 401 and 402:

SECTION BR DATSUN 280Z MODEL S30 SE

- Page 403 and 404:

BRAKE PEDAL The brake pedal is inst

- Page 405 and 406:

BRAKE LINE The brake lines branched

- Page 407 and 408:

1, Appearance of NP-valve for S30 s

- Page 409 and 410:

INSPECTION 1. fl?&> pad with carbon

- Page 411 and 412:

Brake System REPLACING BRAKE SHOE R

- Page 413 and 414:

Brake System 1. When assembling whe

- Page 415 and 416:

Brake System MASTER-VAC CONTENTS DE

- Page 417 and 418:

described under "Inspection" before

- Page 419 and 420:

Retainer Brake System 3. Before ins

- Page 421 and 422:

Brake System Tightening torque Unit

- Page 423 and 424:

Brake System Condition Probable cau

- Page 425:

Brake System SPECIAL SERVICE TOOLS

- Page 428 and 429:

Wheel and Tire WHEEL AND TIRE CONTE

- Page 430 and 431:

When dynamic balance is required, t

- Page 433 and 434:

M SECTION ST DATSUN 280Z MODEL S30

- Page 435 and 436:

impact. Thus, if the car should be

- Page 437 and 438:

Steering System 1 Steering wheel 2

- Page 439 and 440:

Steering System Note: Do not assemb

- Page 441 and 442:

Steering System Side rod inner ball

- Page 443 and 444:

Steering System Clearance 2 mm (0.0

- Page 445 and 446:

Steering System TIGHTENING TORQUE C

- Page 447 and 448:

Steering System 3. Instability of c

- Page 449:

Steering System Possible cause Corr

- Page 452 and 453:

ngine Control, Fuel & Exhaust Syste

- Page 454 and 455:

Engine Control, Fuel & Exhaust Syst

- Page 456 and 457:

Engine Control, Fuel & Exhaust Syst

- Page 458 and 459:

Engine Control, Fuel & Exhaust Syst

- Page 461 and 462:

T£t> *:n • SECTION BF •» DATS

- Page 463 and 464:

Body BF342A Fig. BF-2 Structure of

- Page 465 and 466:

Body Fig. BF-3 Underbody alignment

- Page 467 and 468:

Body BUMPER AND RADIATOR GRILLE CON

- Page 469 and 470:

Body effect]. See Figure BF-10. (5)

- Page 471 and 472:

Fig. BF-19 JF356A Adjusting hood at

- Page 473 and 474:

Body COWL TOP GRILLE AND FRONT FEND

- Page 475 and 476:

ADJUSTMENT TAIL GATE HINGE 1. The f

- Page 477 and 478:

REMOVAL AND INSTALLATION Left door

- Page 479 and 480:

Inside door handle free play 1. Par

- Page 481 and 482:

Body WINDSHIELD GLASS CONTENTS FRON

- Page 483 and 484:

Body TAIL GATE GLASS The instructio

- Page 485 and 486:

Body SEAT BELT CONTENTS DESCRIPTION

- Page 487 and 488:

Body FLOOR CONSOLE REMOVAL AND INST

- Page 489 and 490:

Body BODY SEALING DESCRIPTION Seale

- Page 491 and 492:

SERVICE MANUAL DATSUN 280Z MODEL S3

- Page 493 and 494:

The main cable of each system is ge

- Page 495 and 496:

INSPECTION Inspect all electrical c

- Page 497 and 498:

To antenna motor To rear side marke

- Page 499 and 500:

Body Electrical System LIGHTING AND

- Page 501 and 502:

CIRCUIT DIAGRAM OF LIGHTING SYSTEM

- Page 503 and 504:

Body Electrical System Hazard warni

- Page 505 and 506:

Body Electrical System Clearance an

- Page 507 and 508:

Body Electrical System Meter illumi

- Page 509 and 510:

Body Electrical System Interior lam

- Page 511 and 512:

Body Electrical System Map lamp sys

- Page 513 and 514:

FRONT COMBINATION LAMP Body Electri

- Page 515 and 516:

Body Electrical System LAMP BODY RE

- Page 517 and 518:

COMBINATION SWITCH The combination

- Page 519 and 520:

Body Electrical System \ 1 2 3 4 5

- Page 521 and 522:

Body Electrical System TROUBLE DIAG

- Page 523 and 524:

Body Electrical System 1 2 3 4 5 6

- Page 525 and 526:

Body Electrical System Water temper

- Page 527 and 528:

^ Body Electrical System Brake warn

- Page 529 and 530:

Bulb replacement Pull out socket, w

- Page 531 and 532:

5. Pulling gauge out backward, disc

- Page 533 and 534:

Body Electrical System Hand brake s

- Page 535 and 536:

Body Electrical System Condition Fu

- Page 537 and 538:

Body Electrical System Bl LEVEL AIR

- Page 539 and 540:

Body Electrical System 7. Remove tw

- Page 541 and 542:

Body Electrical System Heater cock

- Page 543 and 544:

Body Electrical System Heater cock

- Page 545 and 546:

Body Electrical System Heater _=_ J

- Page 547 and 548:

Body Electrical System HORN DESCRIP

- Page 549 and 550:

Body Electrical System Horn AT STAR

- Page 551 and 552:

I Body Electrical System ADJUSTMENT

- Page 553 and 554:

TROUBLE DIAGNOSES AND CORRECTIONS B

- Page 555 and 556:

Body Electrical System Windshield w

- Page 557 and 558:

Body Electrical System "High" posit

- Page 559 and 560:

CIGARETTE LIGHTER DESCRIPTION The c

- Page 561 and 562:

REPLACEMENT Clock 1. Remove four sc

- Page 563 and 564:

Body Electrical System BE537 Defogg

- Page 565 and 566:

Body Electrical System i i- Ct < m

- Page 567 and 568:

Body Electrical System 3. Remove bo

- Page 569 and 570:

©*—® Js>J AT STARTER MOTOR 6 FU

- Page 571 and 572:

Body Electrical System Warning buzz

- Page 573 and 574: Body Electrical System KICKDOWN SYS

- Page 575 and 576: Body Electrical System 13 •5, tt

- Page 577 and 578: Body Electrical System c '2 •Sf I

- Page 579 and 580: Body Electrical System STARTER INTE

- Page 581 and 582: Body Electrical System TROUBLE DIAG

- Page 583 and 584: Body Electrical System SEAT SWITCH

- Page 585 and 586: Body Electrical System SEAT BELT WA

- Page 587 and 588: Inspection Remove two screws retain

- Page 589 and 590: Body Electrical System Assistant's

- Page 591 and 592: Body Electrical System Ignition swi

- Page 593 and 594: Body Electrical System Neutral swit

- Page 595 and 596: Body Electrical System Engine revol

- Page 597 and 598: Body Electrical System Emergency sw

- Page 599 and 600: Body Electrical System EMISSION WAR

- Page 601 and 602: Body Electrical System TROUBLE SHOO

- Page 603: Body Electrical System TROUBLE SHOO

- Page 606 and 607: Air Conditioning DESCRIPTION CONTEN

- Page 608 and 609: Air Conditioning REFRIGERATION SYST

- Page 610 and 611: AIR FLOW AND VACUUM SYSTEM AIR FLOW

- Page 612 and 613: Air Conditioning VENT (Ventilation)

- Page 614 and 615: Air Conditioning HEATER (FRESH) pos

- Page 616 and 617: Air Conditioning DEF (Defrost) posi

- Page 618 and 619: Air Conditioning OFF POSITION Ignit

- Page 620 and 621: Air Conditioning GENERAL SERVICE CO

- Page 622 and 623: Air Conditioning r\ Low-pressure ga

- Page 626 and 627: When charging liquefied refrigerant

- Page 628 and 629: (3) Piping • Flared section of hi

- Page 630 and 631: If system has been exposed to atmos

- Page 632 and 633: . condition^ Atr Tightening torque

- Page 634 and 635: Air Conditioning FAST IDLE ACTUATOR

- Page 636 and 637: Air Conditioning 11. In the reverse

- Page 638 and 639: Air Conditioning AC282 Fig. AC-53 1

- Page 640 and 641: Air Conditioning VACUUM HOSE DIAGRA

- Page 642 and 643: CIRCUIT DIAGRAM FOR AIR CONDITIONER

- Page 644 and 645: Noisy Insufficient cooling Blower d

- Page 646 and 647: Air Conditioning Condition Probable

- Page 648 and 649: BLOWER MOTOR DIAGNOSES Air Conditio

- Page 650 and 651: Air Conditioning COMPRESSOR CLUTCH

- Page 652 and 653: Air Conditioning AIR CONDITIONER OP

- Page 654 and 655: j VACUUM SYSTEM DIAGNOSES Air Condi

- Page 656 and 657: Air Conditioning VACUUM SYSTEM DIAG

- Page 658 and 659: Air Conditioning VACUUM SYSTEM DIAG

- Page 660 and 661: Air comes out of defroster nozzles.

- Page 662 and 663: Air Conditioning HOW TO INSTALL AIR

- Page 664 and 665: Air Conditioning III. Install air c

- Page 666 and 667: Air Conditioning 5. Installation of

- Page 668 and 669: Air Conditioning COMPRESSOR CONTENT

- Page 670 and 671: 1 COMPRESSOR CLUTCH The most likely

- Page 672 and 673: INSTALLATION 1. Make sure that the

- Page 674 and 675:

INSPECTION 1. Do not reuse old gask

- Page 676 and 677:

Air Conditioning SERVICE DATA AND S

- Page 678 and 679:

Air Conditioning SPECIAL SERVICE TO

- Page 680 and 681:

Air Conditioning Tool number & tool

- Page 682 and 683:

I A

- Page 684 and 685:

Service Equipment SERVICE EQUIPMENT

- Page 686 and 687:

Service Equipment No. Tool number T