Introduction to the Agilent 7100 Capillary Electrophoresis System

Introduction to the Agilent 7100 Capillary Electrophoresis System

Introduction to the Agilent 7100 Capillary Electrophoresis System

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Maintenance 8<br />

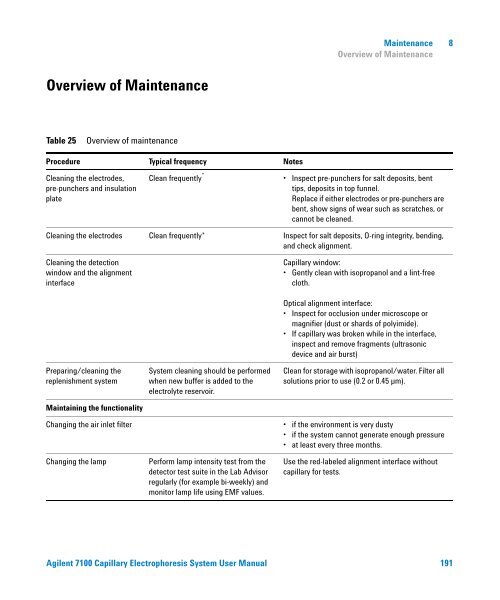

Overview of Maintenance<br />

Overview of Maintenance<br />

Table 25<br />

Overview of maintenance<br />

Procedure Typical frequency Notes<br />

Cleaning <strong>the</strong> electrodes,<br />

pre-punchers and insulation<br />

plate<br />

Clean frequently * • Inspect pre-punchers for salt deposits, bent<br />

tips, deposits in <strong>to</strong>p funnel.<br />

Replace if ei<strong>the</strong>r electrodes or pre-punchers are<br />

bent, show signs of wear such as scratches, or<br />

cannot be cleaned.<br />

Cleaning <strong>the</strong> electrodes Clean frequently* Inspect for salt deposits, O-ring integrity, bending,<br />

and check alignment.<br />

Cleaning <strong>the</strong> detection<br />

window and <strong>the</strong> alignment<br />

interface<br />

<strong>Capillary</strong> window:<br />

• Gently clean with isopropanol and a lint-free<br />

cloth.<br />

Preparing/cleaning <strong>the</strong><br />

replenishment system<br />

Maintaining <strong>the</strong> functionality<br />

<strong>System</strong> cleaning should be performed<br />

when new buffer is added <strong>to</strong> <strong>the</strong><br />

electrolyte reservoir.<br />

Optical alignment interface:<br />

• Inspect for occlusion under microscope or<br />

magnifier (dust or shards of polyimide).<br />

• If capillary was broken while in <strong>the</strong> interface,<br />

inspect and remove fragments (ultrasonic<br />

device and air burst)<br />

Clean for s<strong>to</strong>rage with isopropanol/water. Filter all<br />

solutions prior <strong>to</strong> use (0.2 or 0.45 µm).<br />

Changing <strong>the</strong> air inlet filter • if <strong>the</strong> environment is very dusty<br />

• if <strong>the</strong> system cannot generate enough pressure<br />

• at least every three months.<br />

Changing <strong>the</strong> lamp<br />

Perform lamp intensity test from <strong>the</strong><br />

detec<strong>to</strong>r test suite in <strong>the</strong> Lab Advisor<br />

regularly (for example bi-weekly) and<br />

moni<strong>to</strong>r lamp life using EMF values.<br />

Use <strong>the</strong> red-labeled alignment interface without<br />

capillary for tests.<br />

<strong>Agilent</strong> <strong>7100</strong> <strong>Capillary</strong> <strong>Electrophoresis</strong> <strong>System</strong> User Manual 191