You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

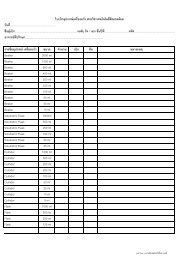

146<br />

evaluation with five scales. The data were<br />

analysed using percentages, means, standard<br />

deviations and t-tests in order to determine the<br />

most popular format in each case. The results<br />

indicated that almost all students appreciated<br />

single column, with the picture at the top of the<br />

page, with 10% yellow tint for the background,<br />

and 16-point rounded AngsanaUPC font.<br />

Therefore, this information could be applied for<br />

page layout design of education print media in<br />

order to satisfy Thai students generally.<br />

IC-203 LEARNING TO DEVELOP PINEAPPLE<br />

LEAF PAPER FOR PRINT MEDIA<br />

Tanatron Tongsumrith, Suchapa Netpradit<br />

The 9 th Baltic Region Seminar on Engineering<br />

Education, June 17-20, 2005, Gdynia, Poland<br />

The objectives of this project were to<br />

develop suitable pineapple leaf paper and to<br />

analyse the paper properties for use as print<br />

media. In this experiment, the different amount<br />

of filler, dry strength and sizing agents were<br />

mixed in pulp stock to study their effects on the<br />

paper's qualities. The pulp was obtained by<br />

boiling the pineapple leaves with sodium<br />

hydroxide solution, and the brownish colour was<br />

bleached out with hydrogen peroxide solution.<br />

The paper sheet was then made by utilising<br />

traditional production processes and the surface<br />

was treated by size pressing and calendering.<br />

The results showed that the optimal amount of<br />

filler, dry strength and sizing agents were 2%,<br />

1.2% and 2% (W/W of dried pulp), respectively,<br />

resulting in appropriate paper qualities. The<br />

pineapple leaf papers had same water absorption<br />

property as commercial wood-free papers, but<br />

the tensile strength was slightly poorer. In<br />

addition, the average whiteness, brightness and<br />

opacity values of the developed pineapple leaf<br />

papers were 31.59, 68.23 and 100, respectively.<br />

This study indicates that the pineapple leaf paper<br />

has a high trend to be used as an alternative<br />

paper for print media.<br />

Faculty of Energy and Materials<br />

IC-204 EFFECT OF DRYING METHODS ON<br />

QUALITY OF COOKED RICE<br />

Pakorn Luangmalawat, Adisak Nathakaranakule,<br />

Somkiat Prachayawarakorn,<br />

Somchart Soponronnarit<br />

International Agricultural Engineering<br />

KMUTT Annual Research Abstracts 2005<br />

Conference, December 6-9, 2005, Bangkok,<br />

Thailand<br />

To obtain a good quality of cooked Thai<br />

jasmine rice, this research is thus focused on the<br />

study of effect of drying methods i.e. heat pump,<br />

hot air, hot air- far infrared drying, heat pumpfar<br />

infrared drying and two-stage drying on the<br />

drying characteristics and the cooked rice<br />

quality. Drying temperature was fixed at 55 o C<br />

for the above-mentioned drying methods, except<br />

for the two-stage drying where the first stage<br />

was set at a temperature of 110 o C followed by<br />

the low temperature of 55 o C at the later stage.<br />

The experimental results showed that the twostage<br />

drying and the hot air-far infrared, as well<br />

as heat pump-far infrared provide shorter drying<br />

time than the hot air or heat pump alone. The<br />

qualities of product i.e. degree of shrinkage and<br />

stickiness obtained from the studied drying<br />

methods were insignificantly different. The<br />

lowest luminosity, but fast rehydration<br />

capability of the two-stage-dried product was<br />

evident whilst the hardness value was relatively<br />

lower.<br />

IC-205 NEW METHOD FOR PRODUCING<br />

PARBOILED RICE UNDER HIGH-<br />

TEMPERATURE SUPERHEATED-STEAM<br />

FLUIDIZATION<br />

Somchart Soponronnarit,<br />

Somkiat Prachayawarakorn,<br />

Chaiyong Taechapairoj<br />

The 4 th Asia Pacific Drying Conference 2005,<br />

December 13-15, 2005, Science City, Kolkata,<br />

India<br />

In order to extremely shorten a long<br />

process time of parboiled-rice production, a new<br />

method for parboiling paddy and brown rice<br />

using superheated-steam fluidization was<br />

investigated. The experimental conditions were<br />

carried out at the initial moisture contents of 39-<br />

42.5% dry basis (d.b.), bed heights of 8-15 cm,<br />

superheated-steam temperatures of 120-170°C<br />

with a constant pressure of 106.1 kPa and a<br />

fixed superficial velocity of 3.1 and 3.9 m/s for<br />

paddy and brown rice, respectively. The<br />

experimental results showed that the inlet<br />

temperature had much more effect on moisture<br />

removal than the bed height. For the rice quality,<br />

reducing moisture content to 28 and 18% d.b., in<br />

case of brown rice and paddy, respectively,<br />

resulted in higher percentage of head rice yield<br />

International Conference