Download - Academy Publisher

Download - Academy Publisher

Download - Academy Publisher

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

After the comprehensive performance testing, the final<br />

data is outputted to the printer, to print the report list and<br />

deposit in database for future query. It possesses at the<br />

same time high efficiency allowing several cars tested[3].<br />

F. standard setting function<br />

Standards setting function the system can adapt to the<br />

state standards or change of local standards by modifying<br />

all testing items standard at any time.<br />

G. faults auto diagnosis and analysis function<br />

Computer networking detection system should be able<br />

to discover our own faults, and analyze and suggest the<br />

parts of the failure to help users for trouble-shooting.<br />

Namely, when the system is running, faults diagnosis' of<br />

mart CARDS, photoelectric switches, each sensor or<br />

circuit, etc should be suggested so as to ensure the normal<br />

running of the detection system[5].<br />

V. HARDWARE COMPOSITIONS<br />

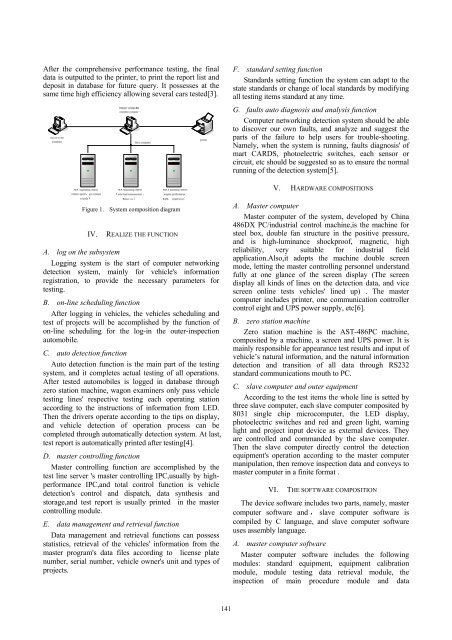

Figure 1. System composition diagram<br />

IV.<br />

REALIZE THE FUNCTION<br />

A. log on the subsystem<br />

Logging system is the start of computer networking<br />

detection system, mainly for vehicle's information<br />

registration, to provide the necessary parameters for<br />

testing.<br />

B. on-line scheduling function<br />

After logging in vehicles, the vehicles scheduling and<br />

test of projects will be accomplished by the function of<br />

on-line scheduling for the log-in the outer-inspection<br />

automobile.<br />

C. auto detection function<br />

Auto detection function is the main part of the testing<br />

system, and it completes actual testing of all operations.<br />

After tested automobiles is logged in database through<br />

zero station machine, wagon examiners only pass vehicle<br />

testing lines' respective testing each operating station<br />

according to the instructions of information from LED.<br />

Then the drivers operate according to the tips on display,<br />

and vehicle detection of operation process can be<br />

completed through automatically detection system. At last,<br />

test report is automatically printed after testing[4].<br />

D. master controlling function<br />

Master controlling function are accomplished by the<br />

test line server 's master controlling IPC,usually by highperformance<br />

IPC,and total control function is vehicle<br />

detection's control and dispatch, data synthesis and<br />

storage,and test report is usually printed in the master<br />

controlling module.<br />

E. data management and retrieval function<br />

Data management and retrieval functions can possess<br />

statistics, retrieval of the vehicles' information from the<br />

master program's data files according to license plate<br />

number, serial number, vehicle owner's unit and types of<br />

projects.<br />

A. Master computer<br />

Master computer of the system, developed by China<br />

486DX PC/industrial control machine,is the machine for<br />

steel box, double fan structure in the positive pressure,<br />

and is high-luminance shockproof, magnetic, high<br />

reliability, very suitable for industrial field<br />

application.Also,it adopts the machine double screen<br />

mode, letting the master controlling personnel understand<br />

fully at one glance of the screen display (The screen<br />

display all kinds of lines on the detection data, and vice<br />

screen online tests vehicles' lined up) . The master<br />

computer includes printer, one communication controller<br />

control eight and UPS power supply, etc[6].<br />

B. zero station machine<br />

Zero station machine is the AST-486PC machine,<br />

composited by a machine, a screen and UPS power. It is<br />

mainly responsible for appearance test results and input of<br />

vehicle’s natural information, and the natural information<br />

detection and transition of all data through RS232<br />

standard communications mouth to PC.<br />

C. slave computer and outer equipment<br />

According to the test items the whole line is setted by<br />

three slave computer, each slave computer composited by<br />

8031 single chip microcomputer, the LED display,<br />

photoelectric switches and red and green light, warning<br />

light and project input device as external devices. They<br />

are controlled and commanded by the slave computer.<br />

Then the slave computer directly control the detection<br />

equipment's operation according to the master computer<br />

manipulation, then remove inspection data and conveys to<br />

master computer in a finite format .<br />

VI.<br />

THE SOFTWARE COMPOSITION<br />

The device software includes two parts, namely, master<br />

computer software and , slave computer software is<br />

compiled by C language, and slave computer software<br />

uses assembly language.<br />

A. master computer software<br />

Master computer software includes the following<br />

modules: standard equipment, equipment calibration<br />

module, module testing data retrieval module, the<br />

inspection of main procedure module and data<br />

141