Download - Academy Publisher

Download - Academy Publisher

Download - Academy Publisher

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

some drilling fluid produces hydrogen sulfide under the<br />

action of high temperature.<br />

Hydrogen sulfide is a gas of colorless, toxic, strong<br />

acid. Hydrogen sulfide gas in low volume fraction has a<br />

smell of rotten eggs, the relative density of which is 1.19.<br />

Compared with air, it is heavy, and it can dissolve in<br />

water. When burning, it accompanied by a blue flame and<br />

produces sulfur dioxide gas that is very harmful to the<br />

person. The mixture of hydrogen sulfide and air, while<br />

mixture gas volume fraction lie the range of 4.3% ~ 45% ,<br />

form a kind of explosive mixture. Hydrogen sulfide is<br />

easy to gather, not easy to drift, often gathering at the<br />

bottom of drilling platform or the lower well site. It can<br />

react with many metals and can corrode of metal severely.<br />

When volume fraction of hydrogen sulfide gas in the air<br />

is greater than 10 × 10-6 , people feel discomfort, and<br />

when that is more than 20 × 10-6, may cause poisoning.<br />

In general, volume fraction of hydrogen sulfide<br />

increases with increasing formation depth. The presence<br />

of hydrogen sulfide is in two forms, either in the form of<br />

hydrogen sulfide gas alone or coexisting with oil and gas;<br />

or in the form of dissolving in water and oil. In drilling<br />

process, the hazards of hydrogen sulfide can be summed<br />

up in four aspects: 1 harm on the human body; 2<br />

corrosion of drilling equipment; 3 contamination of<br />

drilling fluid; 4 pollution of the environment[3].<br />

B. Engineering factors<br />

Geological factor is the objective reality and can not be<br />

changed. If we have better understanding about it and<br />

take corresponding countermeasures, we can turn danger<br />

into safety, reduce the complexity of drilling, and avoid<br />

the accident. Engineering factors is a specific<br />

manifestation of subjective factors, that is construction<br />

design, technical operations, craft measures and so forth<br />

and is suitable for geological factors. It is human factors,<br />

modifiable and adjustable. For engineering factors, see<br />

Table1.<br />

III. COMPREHENSIVE EVALUATION OF DRILLING RISK AND<br />

MODEL BUILDING<br />

Comprehensive evaluation of drilling risk is that the<br />

organization of professionals, based on existing<br />

professional experience, evaluation criteria and<br />

guidelines , identify possible risks or impacts at predrilling<br />

activities, evaluate and analyze scientifically,<br />

calculate the probability ,value and consequences of the<br />

risk by quantifying risk factors, and thus determine<br />

whether the project risk may be accepted. Comprehensive<br />

evaluation methods mainly are analytic hierarchy process,<br />

decision tree method, monte-carlo method, fuzzy<br />

comprehensive evaluation etc. In this paper,<br />

unascertained measure evaluation method is adopted for<br />

analyzing and processing, and its evaluation results can<br />

be quantified accurately. The specific process is as<br />

follows:<br />

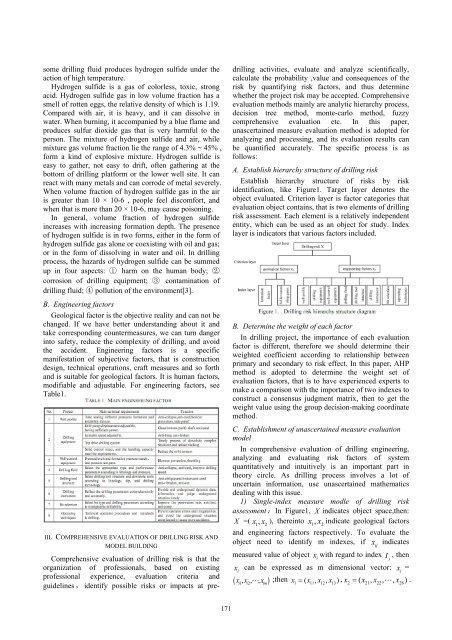

A. Establish hierarchy structure of drilling risk<br />

Establish hierarchy structure of risks by risk<br />

identification, like Figure1. Target layer denotes the<br />

object evaluated. Criterion layer is factor categories that<br />

evaluation object contains, that is two elements of drilling<br />

risk assessment. Each element is a relatively independent<br />

entity, which can be used as an object for study. Index<br />

layer is indicators that various factors included.<br />

B. Determine the weight of each factor<br />

In drilling project, the importance of each evaluation<br />

factor is different, therefore we should determine their<br />

weighted coefficient according to relationship between<br />

primary and secondary to risk effect. In this paper, AHP<br />

method is adopted to determine the weight set of<br />

evaluation factors, that is to have experienced experts to<br />

make a comparison with the importance of two indexes to<br />

construct a consensus judgment matrix, then to get the<br />

weight value using the group decision-making coordinate<br />

method.<br />

C. Establishment of unascertained measure evaluation<br />

model<br />

In comprehensive evaluation of drilling engineering,<br />

analyzing and evaluating risk factors of system<br />

quantitatively and intuitively is an important part in<br />

theory circle. As drilling process involves a lot of<br />

uncertain information, use unascertained mathematics<br />

dealing with this issue.<br />

1) Single-index measure modle of drilling risk<br />

assessment:In Figure1, X indicates object space,then:<br />

X =( x 1<br />

, x 2<br />

), thereinto x 1<br />

, x 2<br />

indicate geological factors<br />

and engineering factors respectively. To evaluate the<br />

object need to identify m indexes, if x indicates<br />

ij<br />

measured value of object x with regard to index<br />

i<br />

I , then<br />

j<br />

x can be expressed as m dimensional vector:<br />

i<br />

x i<br />

=<br />

( x , x , L , x ) ;then x1 = ( x11, x12, x13)<br />

, x2 = ( x21, x22, L , x28)<br />

.<br />

i1 i2<br />

im<br />

171