Download - Academy Publisher

Download - Academy Publisher

Download - Academy Publisher

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ISBN 978-952-5726-09-1 (Print)<br />

Proceedings of the Second International Symposium on Networking and Network Security (ISNNS ’10)<br />

Jinggangshan, P. R. China, 2-4, April. 2010, pp. 047-049<br />

Influences of Powder Content on the<br />

Piezomagnetic Effect of Rubber-based Soft<br />

Magnetic Composite Film<br />

Daguo Jiang<br />

College of Mathematic and Physical , Jinggangshan University , Ji’an, China<br />

e-mail: jgsxy_jdg@sohu.com<br />

Abstract—Composite film was preparated from the heat<br />

treated Fe73.5Cu1Nb3Si13.5B9amorphous powders as<br />

reinforced material and butyl rubber as matrix by means of<br />

molding to shape, and its piezomagnetic effect is also tested.<br />

The results showed that the impedance of composite film<br />

decreases with the morer powder content; the rangeability<br />

of impedance increases first and then decreases with<br />

increasing powder content.Piezomagnetic effect of omposite<br />

film is theoretically analyzed with resistance and<br />

capacitance in series model and the conclusions are<br />

consistent with the experimental results<br />

Index Terms—Fe73.5Cu1Nb3Si13.5B9; butyl rubber;<br />

composite film;piezomagnetic effect<br />

I. INTRODUCTION<br />

Strain occurs and the material internal magnetization<br />

state changes when the ferromagnetic materials are under<br />

the action of mechanical force,which resulting in a<br />

significant change in impedance of the phenomenon<br />

called piezomagnetic effect. A variety of pressure<br />

magnetic sensors are developed based on piezomagnetic<br />

effect, including pressure magnetic non-contact torque<br />

sensors, amorphous piezomagnetic acceleration sensors<br />

piezomagnetic pressure sensors [1-2]. In the literatures [3-<br />

5], the skin effect was used for qualitative analyzing the<br />

piezomagnetic effect of rubber-based soft magnetic<br />

composite film. As composite film is large resistivity and<br />

low permeability, and composite film has excellent<br />

piezomagnetic effect under low frequency, so the skin<br />

effect depth under alternating current is bigger than the<br />

film thickness. In this paper, the soft magnetic composite<br />

films were prepared with the non-powder<br />

Fe73.5Cu1Nb3Si13.5B9 as composite phase and the butyl<br />

rubber as base, and the influence of powder content on the<br />

piezomagnetic effect was studied. Theoretically analysis<br />

with resistance and capacitance in series model is done,<br />

which showed the conclusions are consistent with the<br />

experimental results .<br />

II. EXPERIMENTAL PRINCIPLES AND METHODS<br />

First, 7.2 μm FeSiB amorphous powders is put into<br />

titanate (NDZ-105) THF solution for surface process; and<br />

then uniformly mix the powder with butyl rubber by<br />

different mass ratio, then add sulfur, paraffin and other<br />

additives for adequate mixing; put the mixture between<br />

the two copper foil papers, pressure forms;finally a<br />

composite film with 200 μm thickness is achieved after<br />

cured at 160 ℃ for 1 hour.<br />

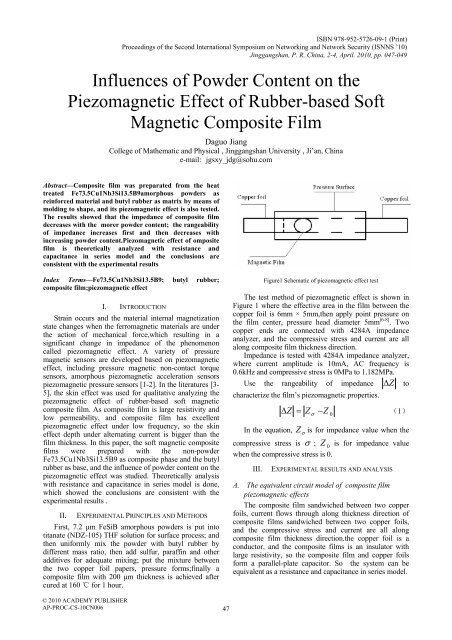

Figure1 Schematic of piezomagnetic effect test<br />

The test method of piezomagnetic effect is shown in<br />

Figure 1 where the effective area in the film between the<br />

copper foil is 6mm × 5mm,then apply point pressure on<br />

the film center, pressure head diameter 5mm [6-8] . Two<br />

copper ends are connected with 4284A impedance<br />

analyzer, and the compressive stress and current are all<br />

along composite film thickness direction.<br />

Impedance is tested with 4284A impedance analyzer,<br />

where current amplitude is 10mA, AC frequency is<br />

0.6kHz and compressive stress is 0MPa to 1.182MPa.<br />

Use the rangeability of impedance ΔZ<br />

to<br />

characterize the film’s piezomagnetic properties.<br />

ΔZ<br />

= Zσ −<br />

(1)<br />

Z 0<br />

In the equation, Zσ<br />

is for impedance value when the<br />

compressive stress is σ ; Z<br />

0<br />

is for impedance value<br />

when the compressive stress is 0.<br />

III.<br />

EXPERIMENTAL RESULTS AND ANALYSIS<br />

A. The equivalent circuit model of composite film<br />

piezomagnetic effects<br />

The composite film sandwiched between two copper<br />

foils, current flows through along thickness direction of<br />

composite films sandwiched between two copper foils,<br />

and the compressive stress and current are all along<br />

composite film thickness direction.the copper foil is a<br />

conductor, and the composite films is an insulator with<br />

large resistivity, so the composite film and copper foils<br />

form a parallel-plate capacitor. So the system can be<br />

equivalent as a resistance and capacitance in series model.<br />

© 2010 ACADEMY PUBLISHER<br />

AP-PROC-CS-10CN006<br />

47