Download - Academy Publisher

Download - Academy Publisher

Download - Academy Publisher

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ISBN 978-952-5726-09-1 (Print)<br />

Proceedings of the Second International Symposium on Networking and Network Security (ISNNS ’10)<br />

Jinggangshan, P. R. China, 2-4, April. 2010, pp. 262-266<br />

CNC System of MKS1632 External Cylindrical<br />

Grinding Machines Based on Embedded<br />

Xuyan Zhou 1,2 , Bin Tan 1 , Bing Zhu 1,2 , XuanGe Peng 1,2 , and Yonghua Pei 3<br />

1 School of Information Science and Communication, Jinggangshan University,Jiangxi,Ji'an 343009<br />

zhouxuyan@jgsu.edu.cn<br />

2 School of Information Engineering, East China Jiaotong University,Jiangxi,Nanchang 330033<br />

Jazhubing@126.com<br />

3 Jiangxi Jack Machine Co.Jiangxi,Ji'an 343000<br />

Abstract—The traditional CNC system based on the IPC is<br />

complex structure, high cost, hardware redundancy and can<br />

not be cut, high power consumption and low reliability, this<br />

paper proposed and designed a CNC System of External<br />

Cylindrical Grinding Machines, and gives the software and<br />

hardware architecture design.The CNC system operation<br />

and management of ARM as the master chip module and<br />

PLC as the master motion control module chip, through the<br />

I / O modules and servo drives and machine I / O connected<br />

to complete the controlling of grinding machine<br />

motion .Design and Implementation of Embedded CNC<br />

edge Cylindrical Grinder grinding system to overcome the<br />

current shortcomings of the system, with versatility, high<br />

reliability, system flexibility, cost-effective high merits in<br />

line with an open CNC system development needs.<br />

Index Term-embeddedsystem; MMI;ceutter radius<br />

compensation<br />

I. INTRODUCTION<br />

MKS1632 CNC cylindrical grinding machine is a<br />

high-end ARM, as well as programmable logic controller<br />

as the core of the numerical control system, using threeaxis<br />

CNC two-axis can be realized into a sports show,<br />

radial feed movement precise digital control.Processing,<br />

through the man-machine interface, data input processing,<br />

use the control panel to issue a variety of operation<br />

commands. Programmable logic controller inverter<br />

spindle realize stepless speed regulation, in order to meet<br />

the requirements of processing technology. To meet the<br />

processing technology, designed the right cut, left-cut,<br />

continuous processing method, using a radial cut into the<br />

descending spiral of feeding method.In order to improve<br />

machining accuracy, positioning accuracy, backlash<br />

compensation is studied.<br />

used in various components of the installation and<br />

connection, the internal module is equipped with<br />

numerical control, human-computer control module,<br />

programmable logic controller (PLC), network<br />

communication module, monitoring circuit.<br />

All the features of the CNC system consists of two<br />

microprocessors CNC-CPU and the PLC-CPU and the<br />

serial communication interface-sharing, communication<br />

between the various parts of the completion by the<br />

internal bus.CNC-CPU for each channel of data<br />

preprocessing and interpolation calculations. Here, each<br />

one channel is a stand-alone system, with multiple axes<br />

and independent of the CNC machining procedure that<br />

requires a corresponding pre-processing procedures and<br />

the interpolation processing, also asked the various<br />

channels can be parallel processing of NC processing<br />

program, each channel by the PLC is responsible for the<br />

coordination. PLC-CPU instruction by receiving T and M<br />

switch command, a variety of electrical machine control,<br />

machine control panel is also responsible for handling<br />

input.<br />

DESIGN OF CNC SYSTEM<br />

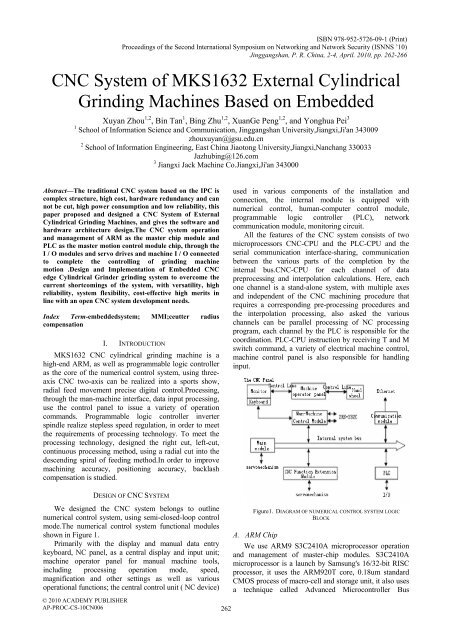

We designed the CNC system belongs to outline<br />

numerical control system, using semi-closed-loop control<br />

mode.The numerical control system functional modules<br />

shown in Figure 1.<br />

Primarily with the display and manual data entry<br />

keyboard, NC panel, as a central display and input unit;<br />

machine operator panel for manual machine tools,<br />

including processing operation mode, speed,<br />

magnification and other settings as well as various<br />

operational functions; the central control unit ( NC device)<br />

© 2010 ACADEMY PUBLISHER<br />

AP-PROC-CS-10CN006<br />

262<br />

Figure1. DIAGRAM OF NUMERICAL CONTROL SYSTEM LOGIC<br />

BLOCK<br />

A. ARM Chip<br />

We use ARM9 S3C2410A microprocessor operation<br />

and management of master-chip modules. S3C2410A<br />

microprocessor is a launch by Samsung's 16/32-bit RISC<br />

processor, it uses the ARM920T core, 0.18um standard<br />

CMOS process of macro-cell and storage unit, it also uses<br />

a technique called Advanced Microcontroller Bus