Download - Academy Publisher

Download - Academy Publisher

Download - Academy Publisher

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

B. Influences of powder content on the impedance of<br />

composite film<br />

Table I is the influences of powder content on the<br />

impedance of composite film at 0.6kHz . Known from<br />

table, the impedance of composite film decreases with the<br />

powder content increases.<br />

The impedance of composite film is consisting of<br />

resistance and reactance. Resistance is mainly depending<br />

on the degree of perfection (resistivity) of amorphous<br />

powder particle chains forming in the rubber base and the<br />

effective length of composite film that the current flows<br />

through;reactance of composite film is decided by the<br />

capacitance, which mainly depends on the thickness of<br />

composite film and the AC frequency.So the impedance<br />

of composite film is:<br />

Z +<br />

2 2<br />

= R X<br />

(2)<br />

The powder content is defined as P ,the composite<br />

film resistivity and dielectric constant decrease with the<br />

bigger powder content P ,it means that,the resistance and<br />

resistance decreases with the bigger powder content P ,<br />

so the impedance of composite film decreases along with<br />

the powder content P increases.<br />

Table I Influences of powder content on the impedance of composite<br />

film<br />

Z/ kΩ<br />

σ/MPa 1:3 1:4 1:5 1:6<br />

0 2159.39 1439.92 1397 938.626<br />

0.065 2153.53 1425.87 1393.65 936.747<br />

0.108 2153.24 1423.35 1393.31 936.32<br />

0.147 2152.77 1422.75 1392.94 935.79<br />

0.201 2152.72 1421.83 1392.52 935.294<br />

0.397 2151.69 1420.89 1391.43 934.167<br />

0.607 2150.72 1420.23 1390 933.391<br />

0.802 2150.69 1417.21 1389.14 932.184<br />

0.992 2150.04 1415.58 1388.55 931.797<br />

1.182 2149.53 1412.13 1387.99 931.366<br />

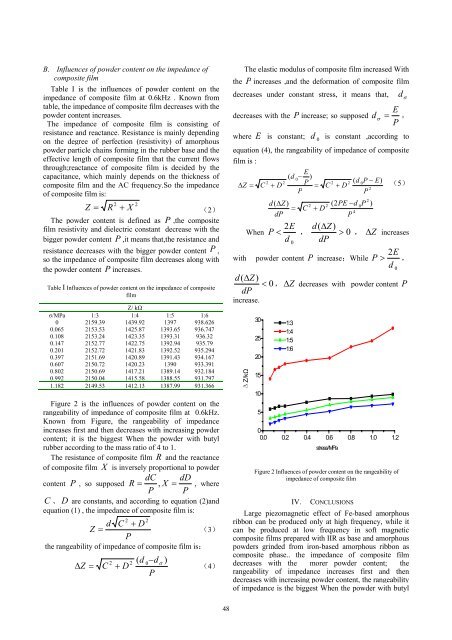

Figure 2 is the influences of powder content on the<br />

rangeability of impedance of composite film at 0.6kHz.<br />

Known from Figure, the rangeability of impedance<br />

increases first and then decreases with increasing powder<br />

content; it is the biggest When the powder with butyl<br />

rubber according to the mass ratio of 4 to 1.<br />

The resistance of composite film R and the reactance<br />

of composite film X is inversely proportional to powder<br />

dC dD<br />

content P , so supposed R = , X = , where<br />

P P<br />

C 、 D are constants, and according to equation (2)and<br />

equation (1) , the impedance of composite film is:<br />

d C<br />

2 2<br />

+ D<br />

Z = (3)<br />

P<br />

the rangeability of impedance of composite film is:<br />

2 2 ( d<br />

0−dσ<br />

)<br />

Δ Z = C + D<br />

(4)<br />

P<br />

The elastic modulus of composite film increased With<br />

the P increases ,and the deformation of composite film<br />

decreases under constant stress, it means that,<br />

decreases with the P increase; so supposed<br />

E<br />

d =<br />

P<br />

d<br />

σ<br />

σ<br />

,<br />

where E is constant; d<br />

0<br />

is constant ,according to<br />

equation (4), the rangeability of impedance of composite<br />

film is :<br />

E<br />

( d<br />

0−<br />

)<br />

2 2 P<br />

2 2 ( d<br />

0P<br />

− E)<br />

Δ Z = C + D = C + D<br />

(5)<br />

2<br />

P<br />

P<br />

2<br />

d(<br />

ΔZ)<br />

2 2 (2PE<br />

−d<br />

0P<br />

)<br />

= C + D<br />

4<br />

dP<br />

P<br />

When<br />

2E<br />

d(<br />

ΔZ)<br />

P < , > 0<br />

d dP<br />

0<br />

, ΔZ<br />

increases<br />

2E<br />

with powder content P increase;While P > ,<br />

d<br />

0<br />

d(<br />

ΔZ)<br />

< 0 , Δ Z decreases with powder content P<br />

dP<br />

increase.<br />

ΔZ/kΩ<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

1:3<br />

1:4<br />

1:5<br />

1:6<br />

0<br />

0.0 0.2 0.4 0.6 0.8 1.0 1.2<br />

stress/MPa<br />

Figure 2 Influences of powder content on the rangeability of<br />

impedance of composite film<br />

IV. CONCLUSIONS<br />

Large piezomagnetic effect of Fe-based amorphous<br />

ribbon can be produced only at high frequency, while it<br />

can be produced at low frequency in soft magnetic<br />

composite films prepared with IIR as base and amorphous<br />

powders grinded from iron-based amorphous ribbon as<br />

composite phase.. the impedance of composite film<br />

decreases with the morer powder content; the<br />

rangeability of impedance increases first and then<br />

decreases with increasing powder content, the rangeability<br />

of impedance is the biggest When the powder with butyl<br />

48