How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

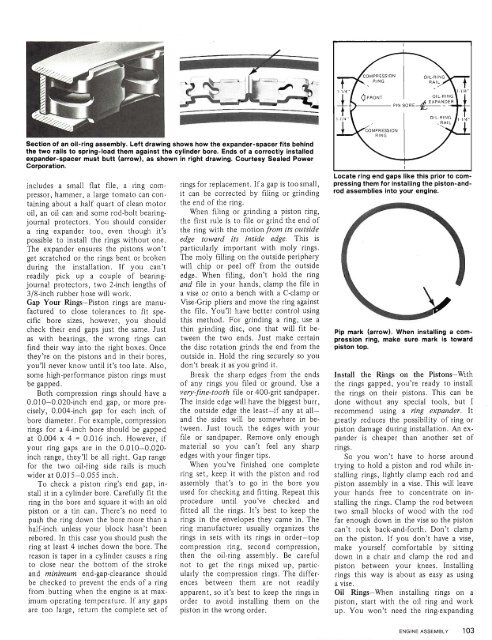

Section <strong>of</strong> an oil-ring assembly. Left drawing shows how the expander-spacer fits behind<br />

the two rails to spring-load them against the cylinder bore. Ends <strong>of</strong> a correctly installed<br />

expander-spacer must butt (arrow), as shown in right drawing. Courtesy Sealed Power<br />

Corporation.<br />

Locate ring end gaps like this prior to comincludes<br />

a small flat file, a ring com- rings for replacement. If a gap is too small, pressing them for installing the piston-and-<br />

'Od<br />

pressor. hammer. a large tomato can con- it can be corrected by filing or grinding your engine.<br />

taining about a half quart <strong>of</strong> clean motor<br />

oil, an oil can and some rod-bolt bearingjournal<br />

protectors. You should consider<br />

a ring expander too, even though it's<br />

possible to install the rings without one.<br />

The expander ensures the pistons won't<br />

get scratched or the rings bent or broken<br />

during the installation. If you can't<br />

readily pick up a couple <strong>of</strong> bearingjournal<br />

protectors, two 2-inch lengths <strong>of</strong><br />

318-inch rubber hose will work.<br />

Gap <strong>Your</strong> Rings-Piston rings are manufactured<br />

to close tolerances to fit specific<br />

bore sizes, however, you should<br />

check their end gaps just the same. Just<br />

as with bearings, the wrong rings can<br />

find their way into the right boxes. Once<br />

they're on the pistons and in their bores,<br />

you'll never know until it's too late. Also,<br />

some high-performance piston rings must<br />

be gapped.<br />

Both compression rings should have a<br />

0.010-0.020-inch end gap, or more precisely,<br />

0.004-inch gap for each inch <strong>of</strong><br />

bore diameter. For example, compression<br />

rings for a 4-inch bore should be gapped<br />

at 0.004 x 4 = 0.016 inch. <strong>How</strong>ever, if<br />

your ring gaps are in the 0.010-0.020-<br />

inch range, they'll be all right. Gap range<br />

for the two oil-iing side rails is much<br />

wider at 0.015-0.055 inch.<br />

<strong>To</strong> check a piston ring's end gap, install<br />

it in a cylinder bore. Carefully fit the<br />

ring in the bore and square it with an old<br />

piston or a tin can. There's no need to<br />

hush the ring down the bore more than a<br />

half-inch unless your block hasn't been<br />

rebored. In this case you should push the<br />

ring at least 4 inches down the bore. The<br />

reason is taper in a cylinder causes a ring<br />

to close near the bottom <strong>of</strong> the stroke<br />

and minimum end-gap-clearance should<br />

be checked to prevent the ends <strong>of</strong> a ring<br />

from butting when the engine is at maximum<br />

operating temperature. If any gaps<br />

are too large, return the complete set <strong>of</strong><br />

-<br />

the end <strong>of</strong> the ring.<br />

When filing or grinding a piston ring,<br />

the first rule is to file or grind the end <strong>of</strong><br />

the ring with the motion from its outside<br />

edge toward its inside edge. Ths is<br />

particularly important with moly rings.<br />

The moly filling on the outside periphery<br />

will chip or peel <strong>of</strong>f from the outside<br />

edge. When filing, don't hold the ring<br />

and file in your hands, clamp the file in<br />

a vise or onto a bench with a C-clamp or<br />

Vise-Grip pliers and move the ring against<br />

the file. You'll have better control using<br />

this method. For grinding a ring, use a<br />

thin grinding disc, one that will fit be-<br />

tween the two ends. Just make certain<br />

the disc rotation grinds the end from the<br />

outside in. Hold the ring securely so you<br />

don't break it as you grind it.<br />

Break the sharp edges from the ends<br />

pip mark (arrow). when installing a<br />

pression ring, make sure mark is toward<br />

piston top.<br />

Install the Rings on the Pistons-With<br />

<strong>of</strong> any rings you filed or ground. Use a the rings gapped, you're ready to install<br />

very-fine-tooth file or <strong>400</strong>-grit sandpaper. the rings on their pistons. This can be<br />

The inside edge will have the biggest burr, done without any special tools, but I<br />

the outside edge the least-if any at all- recommend using a ring expander. It<br />

and the sides will be somewhere in be- greatly reduces the possibility <strong>of</strong> ring or<br />

tween. Just touch the edges with your piston damage during installation. An exfile<br />

or sandpaper. Remove only enough pander is cheaper than another set <strong>of</strong><br />

material so you can't feel any sharp rings.<br />

edges with your finger tips.<br />

So you won't have to horse around<br />

When you've finished one complete trying to hold a piston and rod while inring<br />

set, keep it with the piston and rod stalling rings, lightly clamp each rod and<br />

assembly that's to go in the bore you piston assembly in a vise. This will leave<br />

used for checking and fitting. Repeat this your hands free to concentrate on inprocedure<br />

until you've checked and stalling the rings. Clamp the rod between<br />

fitted all the rings. It's best to keep the two small blocks <strong>of</strong> wood with the rod<br />

rings in the envelopes they came in. The far enough down in the vise so the piston<br />

ring manufacturer usually organizes the can't rock back-and-forth. Don't clamp<br />

rings in sets with its rings in order-top on the piston. If you don't have a vise,<br />

compression ring, second compression, make yourself comfortable by sitting<br />

then the oil-ring assembly. Be careful down in a chair and clamp the rod and<br />

not to get the rings mixed up, partic- piston between your knees. Installing<br />

ularly the compression rings. The differ- rings this way is about as easy as using<br />

ences between them are not readily a vise.<br />

apparent, so it's best to keep the rings in Oil Rings-When installing rings on a<br />

order to avoid installing them on the piston, start with the oil ring and work<br />

piston in the wrong order.<br />

up. You won't need the ring-expanding