How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

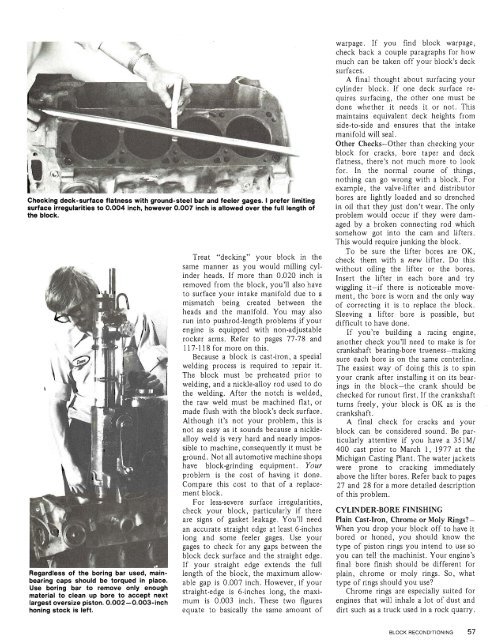

Checking deck-surface flatness with ground-steel bar and feeler gages. I prefer limiting<br />

surface irregularities to 0.004 inch, however 0.007 inch is allowed over the full length <strong>of</strong><br />

the block.<br />

Regardless <strong>of</strong> the boring bar used, mainbearing<br />

caps should be torqued in place.<br />

Use boring bar to remove only enough<br />

material to clean up bore to accept next<br />

largest oversize piston. 0.002-0.003-inch<br />

honing stock is left.<br />

Treat "decking"<br />

- .<br />

your block in the<br />

same manner as you would milling cylinder<br />

heads. If more than 0.020 inch is<br />

removed from the block, you'll also have<br />

to surface your intake manifold due to a<br />

mismatch being created between the<br />

heads and the manifold. You may also<br />

run into pushrod-length problems if your<br />

engine is equipped with non-adjustable<br />

rocker arms. Refer to pages 77-78 and<br />

117-118 for more on this.<br />

Because a block is cast-iron, a special<br />

welding process is required to repair it.<br />

The block must be preheated prior to<br />

welding, and a nickle-alloy rod used to do<br />

the welding. After the notch is welded,<br />

the raw weld must be machined flat, or<br />

made flush with the block's deck surface.<br />

Although it's not your problem, this is<br />

not as easy as it sounds because a nicklealloy<br />

weld is very hard and nearly impossible<br />

to machine, consequently it must be<br />

ground. Not all automotive machine shops<br />

have block-grinding equipment. <strong>Your</strong><br />

problem is the cost <strong>of</strong> having it done.<br />

Compare this cost to that <strong>of</strong> a replacement<br />

block.<br />

For less-severe surface irregularities,<br />

check your block, particularly if there<br />

are signs <strong>of</strong> gasket leakage. You'll need<br />

an accurate straight edge at least 6-inches<br />

long and some feeler gages. Use your<br />

gages to check for any gaps between the<br />

block deck surface and the straight edge.<br />

If your straight edge extends the full<br />

length <strong>of</strong> the block, the maximum allowable<br />

gap is 0.007 inch. <strong>How</strong>ever, if your<br />

straight-edge is 6-inches long, the maximum<br />

is 0.003 inch. These two figures<br />

equate to basically the same amount <strong>of</strong><br />

warpage. If you find block warpage,<br />

check back a couple paragraphs for how<br />

much can be taken <strong>of</strong>f your block's deck<br />

surfaces.<br />

A final thought about surfacing your<br />

cylinder block. If one deck surface requires<br />

surfacing, the other one must be<br />

done whether it needs it or not. This<br />

maintains equivalent deck heights from<br />

side-to-side and ensures that the intake<br />

manifold will seal.<br />

Other Checks-Other than checking your<br />

block for cracks, bore taper and deck<br />

flatness, there's not much more to look<br />

for. In the normal course <strong>of</strong> things,<br />

nothing can go wrong with a block. For<br />

example, the valve-lifter and distributor<br />

bores are lightly loaded and so drenched<br />

in oil that they just don't wear. The only<br />

problem would occur if they were damaged<br />

by a broken connecting rod which<br />

somehow got into the cam and lifters.<br />

This would require junking the block.<br />

<strong>To</strong> be sure the lifter bores are OK,<br />

check them with a new lifter. Do this<br />

without oiling the lifter or the bores.<br />

Insert the lifter in each bore and trv<br />

wiggling it-if there is noticeable movement,<br />

the bore is worn and the only way<br />

<strong>of</strong> correcting it is to replace the block.<br />

Sleeving a lifter bore is possible, but<br />

difficult to have done.<br />

If you're building a racing engine,<br />

another check you'll need to make is for<br />

crankshaft bearing-bore trueness-making<br />

sure each bore is on the same centerline.<br />

The easiest way <strong>of</strong> doing this is to spin<br />

your crank after installing it on its bearings<br />

in the block-the crank should be<br />

checked for runout first. If the crankshaft<br />

turns freely, your block is OK as is the<br />

crankshaft.<br />

A final check for cracks and your<br />

block can be considered sound. Be particularly<br />

attentive if you have a <strong>351M</strong>/<br />

<strong>400</strong> cast prior to March 1, 1977 at the<br />

Michigan Casting Plant. The water jackets<br />

were prone to cracking immediately<br />

above the lifter bores. Refer back to pages<br />

27 and 28 for a more detailed description<br />

<strong>of</strong> this problem.<br />

CYLINDER-BORE FINISHING<br />

Plain Cast-Iron, Chrome or Moly Rings-<br />

When you drop your block <strong>of</strong>f to have it<br />

bored or honed, you should know the<br />

type <strong>of</strong> piston rings you intend to use so<br />

you can tell the machinist. <strong>Your</strong> engine's<br />

final bore finish should be different for<br />

plain, chrome or moly rings. So, what<br />

type <strong>of</strong> rings should you use<br />

Chrome rings are especially suited for<br />

engines that will inhale a lot <strong>of</strong> dust and<br />

dirt such as a truck used in a rock quarry.