How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1 and Assembly<br />

I saved cylinder-head teardown and<br />

inspection until now because once you<br />

start disassembling your heads, you<br />

should continue working with them until<br />

the job is completed. This greatly reduces<br />

the possibility <strong>of</strong> losing or mixing pieces.<br />

Head reconditioning is a precise, tedious<br />

and dirty job requiring special tools and<br />

equipment. It's best to limit your head<br />

work to removing and installing unless<br />

you have the equipment and experience<br />

to do the job. You may do more harm<br />

than good if you attempt to do more.<br />

Leave the precision work to the specialist.<br />

It'll cost you no more for him to strip<br />

your heads too. <strong>How</strong>ever, if you have<br />

access to some or all <strong>of</strong> the equipment,<br />

by all means do it yourself. You can then<br />

inspect all the parts so you'll have an idea<br />

<strong>of</strong> what work needs doing to get your<br />

heads back into shape.<br />

Rail-Rocker-toSpringRetainer Clearance-<br />

If you have a pre-1972 <strong>429</strong>, it will be<br />

equipped with the rail-type rocker arms.<br />

Check the clearance between the rockerarm<br />

rails and the accompanying spring<br />

retainer. This dimension should not be<br />

less than 0.0625 inch (1/I 6 inch)-original<br />

clearance is about 0.080 inch. The<br />

reason this check is so important is it's<br />

possible the valve-stem tip and rocker<br />

arm will wear to a point where this clearance<br />

is reduced to nothing. Consequently,<br />

the rocker-arm rails bean to bear on the<br />

spring retainer, eventually causing the<br />

keepers to come loose. If this happens,<br />

the valve is free to drop into its cylinder,<br />

resulting in considerable engine damage.<br />

In fact, a dropped valve can literally destroy<br />

an engine, so be attentive when<br />

making this check.<br />

Locate each rocker arm in its normal<br />

position on its valve-stem tip and measure<br />

the clearance between the rails and the<br />

spring retainer. A six-inch scale is handy<br />

for doing this, or use a 0.0625-inch-<br />

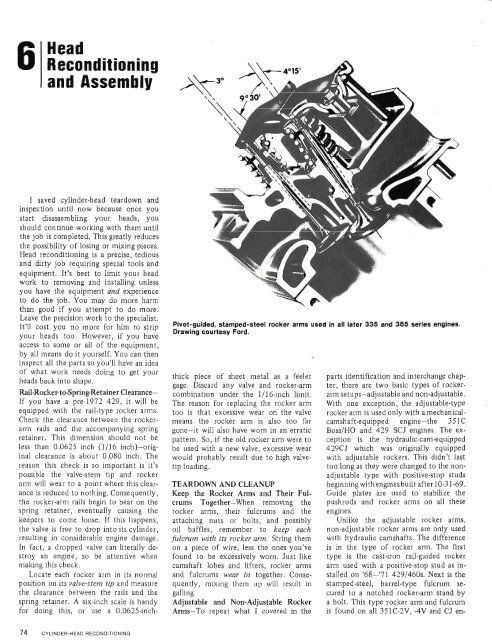

Pivot-guided, stamped-steel rocker arms used in all lator 335 and 385 series engines.<br />

Drawing courtesy <strong>Ford</strong>.<br />

thck piece <strong>of</strong> sheet metal as a feeler<br />

gage. Discard any valve and rocker-arm<br />

combination under the 1116-inch limit.<br />

The reason for replacing the rocker arm<br />

too is that excessive wear on the valve<br />

means the rocker arm is also too far<br />

gone-it will also have worn in an erratic<br />

pattern. So, if the old rocker arm were to<br />

be used with a new valve, excessive wear<br />

would probably result due to high valvetip<br />

loading.<br />

TEARDOWN AND CLEANUP<br />

Keep the Rocker Arms and Their Fulcrums<br />

<strong>To</strong>gether-When removing the<br />

rocker arms, their fulcrums and the<br />

attaching nuts or bolts, and possibly<br />

oil baffles, remember to keep each<br />

fulcnim with its rocker am. String them<br />

on a piece <strong>of</strong> wire, less the ones you've<br />

found to be excessively worn. Just like<br />

camshaft lobes and lifters, rocker arms<br />

and fulcrums wear in together. Consequently,<br />

mixing them up will result in<br />

galling.<br />

Adjustable and Non-Adjustable Rocker<br />

Arm-<strong>To</strong> repeat what I covered in the<br />

parts identification and interchange chapter,<br />

there are two basic types <strong>of</strong> rockerarm<br />

setups-adjustable and non-adjustable.<br />

With one exceptidn, the adjustable-type<br />

rocker arm is used only with a mechanicalcamshaft-equipped<br />

engine-the 35 1 C<br />

Boss/HO and <strong>429</strong> SCJ engines. The exception<br />

is the hydraulic-cam-equipped<br />

<strong>429</strong>CJ which was originally equipped<br />

with adjustable rockers. This didn't last<br />

too long as they were changed to the nonadjustable<br />

type with positive-stop studs<br />

beginning withenginesbuilt after 10-3 1-69.<br />

Guide plates are used to stabilize the<br />

pushrods and rocker arms on all these<br />

engines.<br />

Unlike the adjustable rocker arms,<br />

non-adjustable rocker arms are only used<br />

with hydraulic camshafts. The difference<br />

is in the type <strong>of</strong> rocker arm. The first<br />

type is the cast-iron rail-guided rocker<br />

arm used with a positive-stop stud as installed<br />

on '68-71 <strong>429</strong>1460s. Next is the<br />

stamped-steel, barrel-type fulcrum secured<br />

to a notched rocker-arm stand by<br />

a bolt. This type rocker arm and fulcrum<br />

is found on all <strong>351C</strong>-2V, -4V and CJ en-