How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

UPPER<br />

COMPRESSION<br />

RING<br />

PISTON<br />

PIN<br />

BOLT -<br />

-<br />

LOWER<br />

COMPRESSION<br />

G<br />

L RlNG<br />

SEMBLY<br />

I<br />

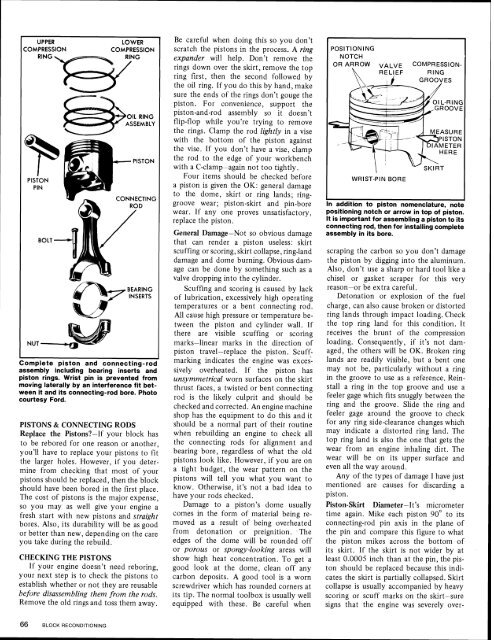

Complete piston and connecting-rod<br />

assembly including bearing inserts and<br />

piston rings. Wrist pin is prevented from<br />

moving laterally by an interference fit between<br />

it and its connecting-rod bore. Photo<br />

courtesy <strong>Ford</strong>.<br />

PISTONS & CONNECTING RODS<br />

Replace the Pistons-If your block has<br />

to be rebored for one reason or another,<br />

you'll have to replace your pistons to fit<br />

the larger holes. <strong>How</strong>ever, if you determine<br />

from checking that most <strong>of</strong> your<br />

pistons should be replaced, then the block<br />

should have been bored in the iirst place.<br />

The cost <strong>of</strong> pistons is the major expense,<br />

so you may as well give your engine a<br />

fresh start with new pistons and straight<br />

bores. Also, its durability will be as good<br />

or better than new, depending on the care<br />

you take during the rebuild.<br />

CHECKING THE PISTONS<br />

If your engine doesn't need reboring,<br />

your next step is to check the pistons to<br />

establish whether or not they are reusable<br />

before disassembling them from the rods.<br />

Remove the old rings and toss them away.<br />

Be careful when doing this so you don't<br />

scratch the pistons in the process. A ring<br />

expander will help. Don't remove the<br />

rings down over the skirt, remove the top<br />

ring first, then the second followed by<br />

the oil ring. If you do this by hand, make<br />

sure the ends <strong>of</strong> tlze rings don't gouge the<br />

piston. For convenience, support the<br />

piston-and-rod assembly so it doesn't<br />

flip-flop while you're trying to remove<br />

the rings. Clamp the rod lightly in a vise<br />

with the bottom <strong>of</strong> the piston against<br />

the vise. If you don't have a vise, clamp<br />

the rod to the edge <strong>of</strong> your workbench<br />

with a C-clamp-again not too tightly.<br />

Four items should be checked before<br />

a piston is given the OK: general damage<br />

to the dome, skirt or ring lands; ringgroove<br />

wear; piston-skirt and pin-bore<br />

wear. If any one proves unsatisfactory,<br />

replace the piston.<br />

General Damage-Not so obvious damage<br />

that can render a piston useless: skirt<br />

scuffing or scoring, skirt collapse, ring-land<br />

damage and dome burning. Obvious damage<br />

can be done by something such as a<br />

valve dropping into the cylinder.<br />

Scuffing and scoring is caused by lack<br />

<strong>of</strong> lubrication, excessively high operating<br />

temperatures or a bent connecting rod.<br />

All cause high pressure or temperature between<br />

the piston and cylinder wall. If<br />

there are visible scuffing or scoring<br />

marks-linear marks in the direction <strong>of</strong><br />

piston travel-replace the piston. Scuffmarking<br />

indicates the engine was excessively<br />

overheated. If the piston has<br />

unsymmetrical worn surfaces on the skirt<br />

thrust faces, a twisted or bent connecting<br />

rod is the likely culprit and should be<br />

checked and corrected. An engine machine<br />

shop has the equipment to do this and it<br />

should be a normal part <strong>of</strong> their routine<br />

when rebuilding an engine to check all<br />

the connecting rods for alignment and<br />

bearing bore, regardless <strong>of</strong> what the old<br />

pistons look like. <strong>How</strong>ever, if you are on<br />

a tight budget, tlze wear pattern on the<br />

pistons will tell you what you want to<br />

know. Otherwise, it's not a bad idea to<br />

have your rods checked.<br />

Damage to a piston's dome usually<br />

comes in the form <strong>of</strong> material being removed<br />

as a result <strong>of</strong> being overheated<br />

from detonation or preignition. The<br />

edges <strong>of</strong> tlze dome will be rounded <strong>of</strong>f<br />

or porous or spongy-looking areas will<br />

show high heat concentration. <strong>To</strong> get a<br />

good look at the dome, clean <strong>of</strong>f any<br />

carbon deposits. A good tool is a worn<br />

screwdriver which has rounded corners at<br />

its tip. The normal toolbox is usually well<br />

equipped with these. Be careful when<br />

POSlTlONl NG<br />

NOTCH<br />

WRIST-PIN BORE<br />

MEASURE<br />

In addition to piston nomenclature, note<br />

positioning notch or arrow in top <strong>of</strong> piston.<br />

It is important for assembling a piston to its<br />

connecting rod, then for installing complete<br />

assembly in its bore.<br />

scraping the carbon so you don't damage<br />

the piston by digging into the aluminum.<br />

Also, don't use a sharp or hard tool like a<br />

chisel or gasket scraper for this very<br />

reason-or be extra careful.<br />

Detonation or explosion <strong>of</strong> the fuel<br />

charge, can also cause broken or distorted<br />

ring lands through impact loading. Check<br />

the top ring land for this condition. It<br />

receives the brunt <strong>of</strong> the compression<br />

loading. Consequently, if it's not damaged,<br />

the others will be OK. Broken ring<br />

lands are readily visible, but a bent one<br />

may not be, particularly without a ring<br />

in the groove - to use as a reference. ~ein;<br />

stall a ring in the top groove and use a<br />

feeler gage which fits snuggly between the<br />

ring and the groove. slide the ring and<br />

feeler gage around the groove to check<br />

for any ring side-clearance changes which<br />

may indicate a distorted ring land. The<br />

top ring land is also the one that gets the<br />

wear from an engine inhaling dirt. The<br />

wear will be on its upper surface and<br />

even all the way around.<br />

Any <strong>of</strong> the types <strong>of</strong> damage I have just<br />

mentioned are causes for discarding a<br />

piston<br />

Piston-Skirt Diameter-It's micrometer<br />

time again. Mike each piston 90' to its<br />

connecting-rod pin axis in the plane <strong>of</strong><br />

the pin and compare this figure-to what<br />

the piston mikes across the bottom <strong>of</strong><br />

its skirt. If the skirt is not wider by at<br />

least 0.0005 inch than at the pin, the piston<br />

should be replaced because this indicates<br />

the skirt is partially collapsed. Skirt<br />

collapse is usually accompanied by heavy<br />

scoring or scuff marks on the skirt-sure<br />

signs that the engine was severely over-