How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

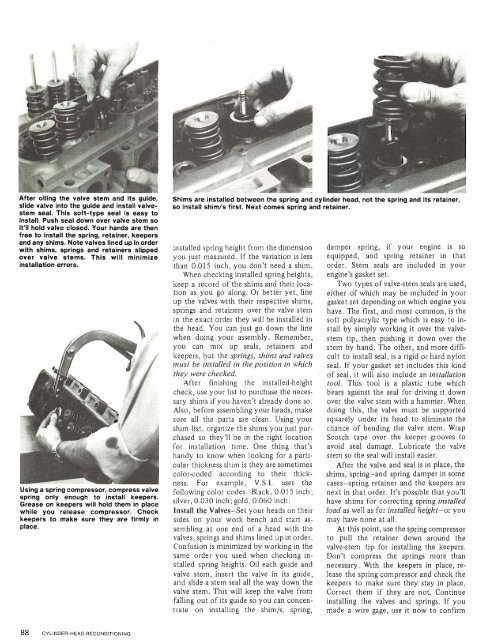

After oiling the valve stem and its guide,<br />

slide valve into the guide and install valvestem<br />

seal. This s<strong>of</strong>t-type seal is easy to<br />

install. Push seal down over valve stem so<br />

it'll hold valve closed. <strong>Your</strong> hands are then<br />

free to install the spring, retainer, keepers<br />

and any shims. Note valves lined up in order<br />

with shims, springs and retainers slipped<br />

over valve stems. This will minimize<br />

installation errors.<br />

Using a spring compressor, compress valve<br />

spring only enough to install keepers.<br />

Grease on keepers will hold them in place<br />

while you release compressor. Check<br />

keepers to make sure they are firmly in<br />

place.<br />

Shims are installed between the spring and cylinder head, not the spring and its retainer,<br />

so install shim/s first. Next comes spring and retainer.<br />

installed spring height from the dimension<br />

you just measured. If the variation is less<br />

than 0.015 inch, you don't need a shim.<br />

When checking installed spring heights,<br />

keep a record <strong>of</strong> the shims and their location<br />

as you go along. Or better yet, line<br />

up the valves with their respective shims,<br />

springs and retainers over the valve stem<br />

in the exact order they wdl be installed in<br />

the head. You can just go down the line<br />

when doing your assembly. Remember,<br />

you can mix up seals, retainers and<br />

keepers, but the springs, shims and valves<br />

must be installed in the position in which<br />

they were checked.<br />

After finishing the installed-height<br />

check, use your list to purchase the necessary<br />

shims if you haven't already done so.<br />

Also, before assembling your heads, make<br />

sure all the parts are clean. Using your<br />

shim list, organize the shims you just purchased<br />

so they'll be in the right location<br />

for installation time. One thing that's<br />

handy to know when looking for a particular<br />

thickness shim is they are sometimes<br />

color-coded according to their thickness.<br />

For example, V.S.I. uses the<br />

following color codes: Black, 0.01 5 inch;<br />

silver, 0.030 inch; gold, 0.060 inch.<br />

Install the Valves-Set your heads on their<br />

sides on your work bench and start assembling<br />

at one end <strong>of</strong> a head with the<br />

valves, springs and shims lined up in order.<br />

Confusion is minimized by working in the<br />

same order you used when checlung installed<br />

spring heights. Oil each guide and<br />

valve stem, insert the valve in its guide,<br />

and slide a stem seal all the way down the<br />

valve stem. This will keep the valve from<br />

falling out <strong>of</strong> its guide so you can concentrate<br />

on installing the shim/s, spring,<br />

damper spring, if your engine is so<br />

equipped, and spring retainer in that<br />

order. Stem seals are included in your<br />

engine's gasket set.<br />

Two types <strong>of</strong> valve-stem seals are used,<br />

either <strong>of</strong> which may be included in your<br />

gasket set depending on which engine you<br />

have. The first, and most common, is the<br />

s<strong>of</strong>t polyacrylic type which is easy to install<br />

by simply working it over the valvestem<br />

tip, then pushing it down over the<br />

stem by hand. The other, and more difficult<br />

to install seal, is a rigid or hard nylon<br />

seal. If your gasket set includes this lund<br />

<strong>of</strong> seal, it will also include an installation<br />

tool. This tool is a plastic tube which<br />

bears against the seal for driving it down<br />

over the valve stem with a hammer. When<br />

doing this, the valve must be supported<br />

squarely under its head to eliminate the<br />

chance <strong>of</strong> bending the valve stem. Wrap<br />

Scotch tape over the keeper g<strong>To</strong>oves to<br />

avoid seal damage. Lubricate the valve<br />

stem so the seal will install easier.<br />

After the valve and seal is in place, the<br />

shims, spring-and spring damper in some<br />

cases-spring retainer and the keepers are<br />

next in that order. It's possible that you'll<br />

have shims for correcting spring installed<br />

load as well as for installed height-or you<br />

may have none at all.<br />

At this point, use the spring compressor<br />

to pull the retainer down around the<br />

valve-stem tip for installing the keepers.<br />

Don't compress the springs more than<br />

necessary. With the keepers in place, release<br />

the spring compressor and check the<br />

keepers to make sure they stay in place.<br />

Correct them if they are not. Continue<br />

installing the valves and springs. If you<br />

made a wire gage, use it now to confirm