How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

30' TOP CUT<br />

INCH WIDTH<br />

L<br />

I<br />

Exhaust valves should have no less than a<br />

1 /32-Inch margln after grinding. Otherwlse<br />

there Is a risk <strong>of</strong> burning It. Intake-valve<br />

margins shouldn't be thinned beyond 1 /64-<br />

Inch.<br />

by the valve spring.<br />

Valve faces are ground on a special<br />

grinder made just for this purpose. The<br />

valve is rotated in a collet-type chuck at<br />

an angle <strong>of</strong> 44' to a fast-turning grinding<br />

wheel. As the valve face rotates against<br />

the wheel's rotation, it is also oscillated<br />

across the face <strong>of</strong> the grinding wheel.<br />

Simultaneously, the valve and stone are<br />

bathed in cutting oil for cooling and to<br />

wash away the grindings. Enough face<br />

material is removed only to expose new<br />

metal on the valve face. If too much<br />

material is removed, the valve's margin<br />

will be thinned excessively and the valve<br />

will have to be junked. The margin <strong>of</strong> a<br />

valve is the thickness at its OD, at the<br />

outer edge <strong>of</strong> the face.<br />

A valve with little or no margin will<br />

approach being sharp at its outer edge<br />

and must be replaced because it's highly<br />

susceptible to burning, particularly if it's<br />

an exhaust valve. An exhaust-valve margin<br />

should be at least 0.030 inch wide-ap-<br />

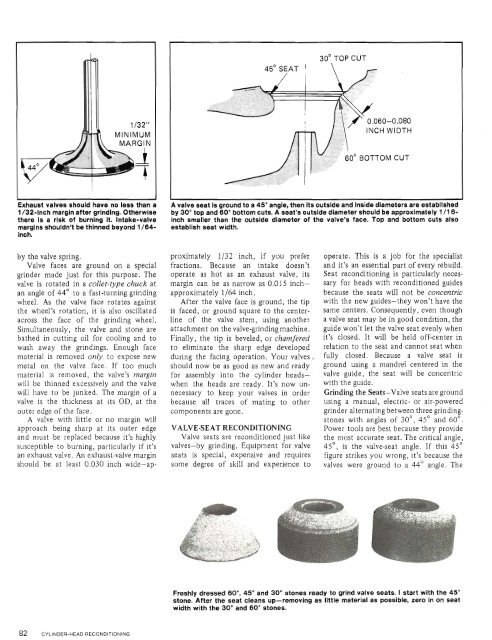

A valve seat Is ground to a 45" angle, then Its outside and Inside diameters are established<br />

by 30" top and 60" bottom cuts. A seat's outside diameter should be approximately 1 /I 6-<br />

inch smaller than the outside diameter <strong>of</strong> the valve's face. <strong>To</strong>p and bottom cuts also<br />

establish seat width.<br />

proximately 1/32 inch, if you prefer<br />

fractions. Because an intake doesn't<br />

operate as hot as an exhaust valve, its<br />

margin can be as narrow as 0.015 inchapproximately<br />

1/64 inch.<br />

After the valve face is ground, the tip<br />

is faced, or ground square to the centerline<br />

<strong>of</strong> the valve stem, using another<br />

attachment on the valve-grinding machine.<br />

Finally, the tip is beveled, or chamfered<br />

to eliminate the sharp edge developed<br />

during the facing operation. <strong>Your</strong> valves<br />

should now be as good as new and ready<br />

for assembly into the cylinder headswhen<br />

the heads are ready. It's now unnecessary<br />

to keep your valves in order<br />

because all traces -<strong>of</strong> mating to other<br />

components are gone.<br />

operate. This is a job for the specialist<br />

and it's an essential part <strong>of</strong> every rebuild.<br />

Seat reconditioning is particularly necessary<br />

for heads with reconditioned guides<br />

because the seats will not be concentric<br />

with the new guides-they won't have the<br />

same centers. Consequently, even though<br />

a valve seat may be in good condition, the<br />

guide won't let the valve seat evenly when<br />

it's closed. It will be held <strong>of</strong>f-center in<br />

relation to the seat and cannot seat when<br />

fully closed. Because a valve seat is<br />

ground using a mandrel centered in the<br />

valve guide, the seat will be concentric<br />

with the guide.<br />

Grinding the Seats-Valve seats are ground<br />

using a manual, electric- or air-powered<br />

grinder alternating between three grindingstones<br />

with angles <strong>of</strong> 30°, 45' and 60".<br />

Power tools are best because they provide<br />

the most accurate seat. The critical angle,<br />

VALVE-SEAT RECONDITIONING<br />

Valve seats are reconditioned just like<br />

valves-by grinding. Equipment for valve 45", is the valve-seat angle. If this 4.5'<br />

seats is special, expensive and requires figure strikes you wrong, it's because the<br />

some degree <strong>of</strong> skill and experience to valves were ground to a 44O angle. The<br />

Freshly dressed 60"' 45" and 30' stones ready to grind valve seats. I start with the 45"<br />

stone. After the seat cleans up-removing as little material as possible, zero in on seat<br />

width with the 30" and 60" stones.