How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

0.020 inch, the next available oversize.<br />

The machinist first bores the cylinder<br />

with the worst wearltaper because it will<br />

establish the maximum oversize for all<br />

the cylinders.<br />

Diai-Bore Gage or Micrometer Method-<br />

When using a bore gage or micrometer<br />

to measure taper, measure the point <strong>of</strong><br />

maximum wear immediately below the<br />

ridge. Because wear will be irregular, take<br />

several measurements around the bore to<br />

determine maximum wear. <strong>To</strong> determine<br />

taper, subtract the measurement at the<br />

bottom <strong>of</strong> the bore from that at the top.<br />

Ring-and-Feeler Method-Measuring bore<br />

wear with a piston ring and feeler gage<br />

is going about it indirectly. When using<br />

this method, you are actually comparing<br />

the difference between the circumferences<br />

<strong>of</strong> the worn and unworn bore. The accuracy<br />

<strong>of</strong> this method is less the more irregularity<br />

a cylinder is worn, however it is<br />

accurate enough to determine whether<br />

you'll need to bore and install oversize<br />

pistons or clean your pistons, hone the<br />

bores and install moly rings.<br />

<strong>To</strong> use the ring-and-feeler method,<br />

place a ring in the cylinder and compare<br />

the difference in ring end gaps with the<br />

ring placed at the bottom <strong>of</strong> the bore and<br />

with it at the top <strong>of</strong> the bore-immediately<br />

below the ridge. Use the same ring.<br />

While it doesn't need to be a new one, it<br />

must be square in the bore to get an<br />

accurate reading. <strong>To</strong> square the'ring, push<br />

it down the cylinder with a bare pistonno<br />

rings-to where you want to check<br />

ring gap. Measure the gap with feeler gages<br />

and record the results. After measuring<br />

the ring end-gap difference, use the<br />

accompanying chart or graph to determine<br />

bore taper. Taper is approximately<br />

0.3 times ring end-gap difference.<br />

<strong>How</strong> Much Taper is Permissible-<strong>To</strong> decide<br />

how much taper your engine can<br />

live with, you'll have to ask yourself how<br />

many more good-miles you want out <strong>of</strong><br />

your engine. Do you want it to last<br />

10,000, 20,000 or 100,000 miles before<br />

oil consumption takes <strong>of</strong>f If your engine<br />

has excessive taper, even new rings will<br />

quickly fatigue and quit sealing. They<br />

must expand and contract to conform to<br />

the irregular bore during every stroke.<br />

Consequently, they lose their resiliency,<br />

or springiness. Also, because ring gap<br />

must be correct as measured at the<br />

bottom <strong>of</strong> the bore, in a tapered bore the<br />

gap will be larger at the top where compression<br />

and combustion pressures are<br />

highest. Consequently, these pressures<br />

will be reduced slightly because <strong>of</strong><br />

increased blowby through the wider<br />

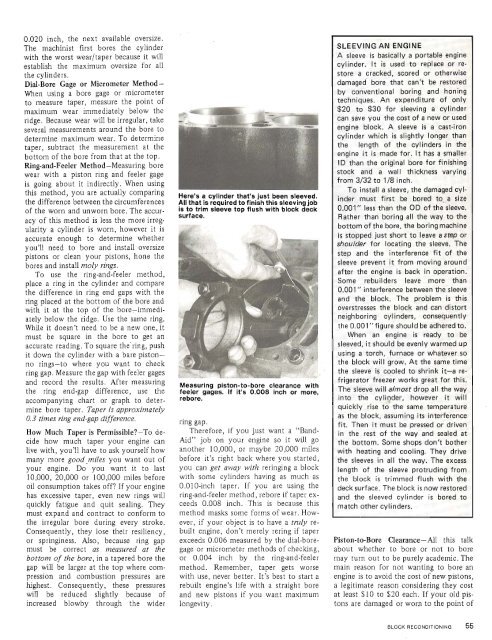

Here's a cylinder that's just been sleeved.<br />

All that is required to finish this sleeving job<br />

is to trim sleeve top flush with block deck<br />

surface.<br />

Measuring piston-to-bore clearance with<br />

feeler gages. If it's 0.008 inch or more,<br />

rebore.<br />

ring gap.<br />

Therefore, if you just want a "Band-<br />

Aid" job on your engine so it will go<br />

another 10,000, or maybe 20,000 miles<br />

before it's right back where you started,<br />

you can get away with reringing a block<br />

with some cylinders having as much as<br />

0.010-inch taper. If you are using the<br />

ring-and-feeler method, rebore if taper exceeds<br />

0.008 inch. This is because this<br />

method masks some forms <strong>of</strong> wear. <strong>How</strong>ever,<br />

if your object is to have a truly rebuilt<br />

engine, don't merely rering if taper<br />

exceeds 0.006 measured by the dial-boregage<br />

or micrometer methods <strong>of</strong> checking,<br />

or 0.004 inch by the ring-and-feeler<br />

method. Remember, taper gets worse<br />

with use, never better. It's best to start a<br />

rebuilt engine's life with a straight bore<br />

and new pistons if you want maximum<br />

longevity.<br />

SLEEVING AN ENGINE<br />

A sleeve is basically a portable engine<br />

cylinder. It is used to replace or restore<br />

a cracked, scored or otherwise<br />

damaged bore that can't be restored<br />

by conventional boring and honing<br />

techniques. An expenditure <strong>of</strong> WI~Y<br />

$20 to $30 for sleeving a cylinder<br />

can save you the cost <strong>of</strong> a new or used<br />

engine block. A sleeve is a cast-iron<br />

cylinder which is slightly longer than<br />

the length <strong>of</strong> the cylinders In the<br />

engine it is made for. It has a smaller<br />

ID than the original bore for finishing<br />

stock and a wall thickness varying<br />

from 3/32 to 118 inch.<br />

<strong>To</strong> install a sleeve, the damaged cylinder<br />

must first be bored to. s size<br />

0.001" less than the OD <strong>of</strong> the sleeve.<br />

Rather than boring all the way to the<br />

bottom <strong>of</strong> be bore, the boring machine<br />

is stopped just short to leave a step or<br />

shoulder for locating the sleeve. The<br />

step and the interference fit <strong>of</strong> the<br />

sleeve prevent it from moving around<br />

after the engine is back in operation.<br />

Some rebuilders leave more than<br />

0.001'' interference between the sleeve<br />

and the block. The problem is this<br />

overstresses the block and can distort<br />

neighboring cylinders, consequently<br />

the 0.001" figure should be adhered to.<br />

When an engine is ready to be<br />

sleeved, it shou!d be evenly warmed up<br />

using a torch, furllace or whatever so<br />

the block will grow. At the same time<br />

the sleeve is cooled to shrink it-a refrigerator<br />

freezer works geat for this.<br />

The sleeve will almost drop all the way<br />

into the cyligder, however it will<br />

quickly rise to the same temperature<br />

as the block, assuming its interference<br />

fit. Then it must be pressed or driven<br />

in the rest <strong>of</strong> the way and sealed at<br />

the bottom. Some shops don't bother<br />

with heating and cooling. They drive<br />

the sleeves in all the way. The excess<br />

length <strong>of</strong> the sleeve protruding from<br />

the block is trimmed flush with the<br />

deck surface. The block is now restored<br />

and the sleeved cylinder is bored to<br />

match other cylinders.<br />

Piston-to-Bore Clearance- All this talk<br />

about whether to bore or not to bore<br />

may turn out to be purely academic. The<br />

main reason for not wanting to bore an<br />

engine is to avoid the cost <strong>of</strong> new pistons,<br />

a legitimate reason considering they cost<br />

at least $10 to $20 each. If your old pistons<br />

are damaged or worn to the point <strong>of</strong><br />

BLOCK RECONDITIONING 55