How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

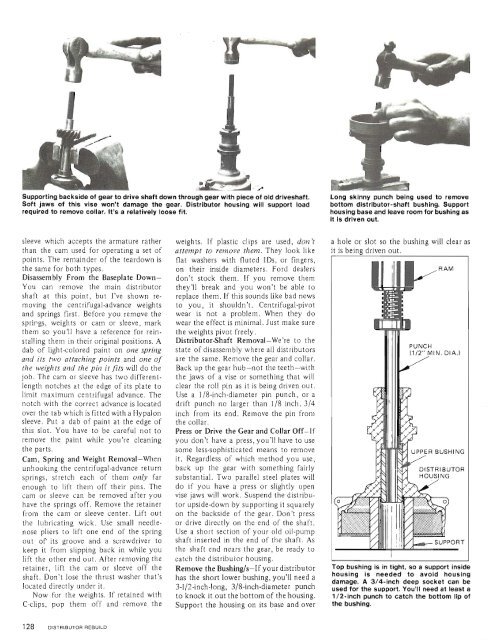

Supporting backside <strong>of</strong> gear to drive shaft down through gear with piece <strong>of</strong> old driveshaft.<br />

S<strong>of</strong>t jaws <strong>of</strong> this vise won't damage the gear. Distributor housing will support load<br />

required to remove collar. It's a relatively loose fit.<br />

Long skinny punch being used to remove<br />

bottom distributor-shaft bushing. Support<br />

housing base and leave room for bushing as<br />

it is driven out.<br />

sleeve which accepts the armature rather<br />

than the cam used for operating a set <strong>of</strong><br />

points. The remainder <strong>of</strong> the teardown is<br />

the same for both types.<br />

Disassembly From the Baseplate Down-<br />

You can rernove the main distributor<br />

shaft at this point, but I've shown removing<br />

the centrifugal-advance weights<br />

and springs first. Before you remove the<br />

spri~gs, weights or cam or sleeve, mark<br />

them so you'll have a reference for reinstalling<br />

them in their original positions. A<br />

dab <strong>of</strong> light-colored paint on one spring<br />

and its hvo attachirzg points and one <strong>of</strong><br />

the weights arzd the pirz it fits will do the<br />

job. The cam or sleeve has two differentlength<br />

notches at the edge <strong>of</strong> its plate to<br />

limit maximum centrifugal advance. The<br />

notch with the correct advance is located<br />

over the tab which is fitted with a Hypalon<br />

sleeve. Put a dab <strong>of</strong> paint at the edge <strong>of</strong><br />

this slot. You have to be careful not to<br />

rernove the paint while you're cleaning<br />

the parts.<br />

Cam, Spring and Weight Removal-When<br />

unhooking the centrifugal-advance return<br />

springs. stretch each <strong>of</strong> them only far<br />

enough to lift them <strong>of</strong>f their pins. The<br />

cam or sleeve can be removed after you<br />

have the springs <strong>of</strong>f. Remove the retainer<br />

from the cam or sleeve center. Lift out<br />

the lubricating wick. Use small needlenose<br />

pliers to lift one end <strong>of</strong> the spring<br />

out <strong>of</strong> its groove and. a screwdriver to<br />

keep it from slipping back in while you<br />

lift the other end out. After removing the<br />

retainer, lift the cam or sleeve <strong>of</strong>f the<br />

shaft. Don't lose the thrust washer that's<br />

located directly under it.<br />

Now for the weights. If retained with<br />

C-clips, pop them <strong>of</strong>f and remove the<br />

weights. If plastic clips are used, don't<br />

attempt to remove them. They look like<br />

flat washers with fluted IDS, or fingers,<br />

on their inside diameters. <strong>Ford</strong> dealers<br />

don't stock them. If you remove them<br />

they'll break and you won't be able to<br />

replace them. If this sounds like bad news<br />

to you, it shouldn't. Centrifugal-pivot<br />

wear is not a problern. When they do<br />

wear the effect is minimal. Just make sure<br />

the weights pivot freely.<br />

DistributorShaft Removal-We're to the<br />

state <strong>of</strong> disassembly where all distributors<br />

are the same. Remove the gear and collar.<br />

Back up the gear hub-not the teeth-with<br />

the jaws <strong>of</strong> a vise or something that will<br />

clear the roll pin as it is being driven out.<br />

Use a 118-inch-diameter pin punch, or a<br />

drift punch no larger than 118 inch. 314<br />

inch from its end. Remove the pin fron~<br />

the collar.<br />

Press or Drive the Gear and Collar Off-If<br />

you don't have a press, you'll have to use<br />

some less-sophisticated means to remove<br />

it. Regardless <strong>of</strong> which method you use,<br />

back up the gear with something fairly<br />

substantial. Two parallel steel plates will<br />

do if you have a press or slightly open<br />

vise jaws will work. Suspend the distributor<br />

upside-down by supporting it squarely<br />

on the backside <strong>of</strong> the gear. Don't press<br />

or drive directly on the end <strong>of</strong> the shaft.<br />

Use a short section <strong>of</strong> your old oil-pump<br />

shaft inserted in the end <strong>of</strong> the shaft. As<br />

the shaft end nears the gear, be ready to<br />

catch the distributor housing.<br />

Remove the Bushingls-If your distributor<br />

has the short lower bushing, you'll need a<br />

3-112-inch-long, 318-inch-diameter punch<br />

to knock it out the bottom <strong>of</strong> the housing.<br />

Support the housing on its base and over<br />

a hole or slot so the bushing will clear as<br />

it is being driven out.<br />

I<br />

I<br />

R BUSHING<br />

1 1<br />

<strong>To</strong>p bushing is in tight, so a support inside<br />

housing is needed to avoid housing<br />

damage. A 3/4-inch deep socket can be<br />

used for the support. You'll need at least a<br />

1/2-inch punch to catch the bottom lip <strong>of</strong><br />

the bushing.