How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

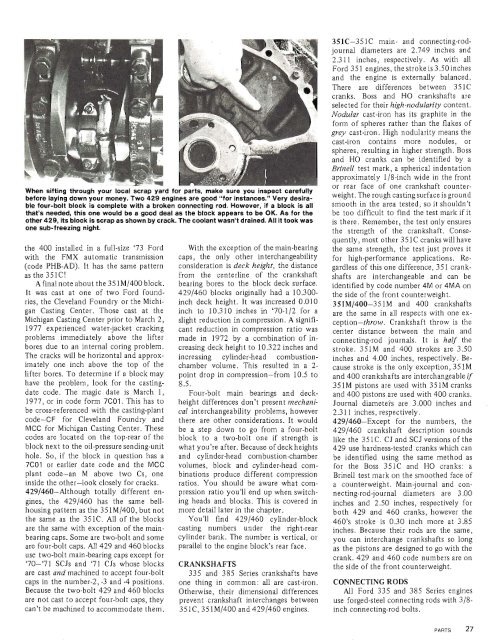

When sifting through your local scrap yard for parts, make sure you inspect carefully<br />

before laying down your money. Two <strong>429</strong> engines are good "for instances." Very desirable<br />

four-bolt block is complete with a broken connecting rod. <strong>How</strong>ever, if a block is all<br />

that's needed, this one would be a good deal as the block appears to be OK. As for the<br />

other <strong>429</strong>, its block is scrap as shown by crack. The coolant wasn't drained. All it took was<br />

one sub-freezing night.<br />

the <strong>400</strong> installed in a full-size '73 <strong>Ford</strong><br />

with the FMX automatic transmission<br />

(code PHB-AD). It has the same pattern<br />

as the <strong>351C</strong>!<br />

A final note about the <strong>351M</strong>/<strong>400</strong> block.<br />

It was cast at one <strong>of</strong> two <strong>Ford</strong> foundries,<br />

the Cleveland Foundry or the Michigan<br />

Casting Center. Those cast at the<br />

Michigan Casting Center prior to March 2,<br />

1977 experienced water-jacket cracking<br />

problems immediately above the lifter<br />

bores due to an internal coring problem.<br />

The cracks will be horizontal and approximately<br />

one inch above the top <strong>of</strong> the<br />

lifter bores. <strong>To</strong> determine if a block may<br />

have the problem, look for the castingdate<br />

code. The magic date is March 1,<br />

1977, or in code form 7C01. This has to<br />

be cross-referenced with the casting-plant<br />

code-CF for Cleveland Foundry and<br />

MCC for Michigan Casting Center. These<br />

codes are located on the top-rear <strong>of</strong> the<br />

block next to the oil-pressure sending-unit<br />

hole. So, if the block in question has a<br />

7C01 or earlier date code and the MCC<br />

plant code-an M above two Cs, one<br />

inside the other-look closely for cracks.<br />

<strong>429</strong>1460-Although totally different engines,<br />

the <strong>429</strong>1460 has the same bellhousing<br />

pattern as the <strong>351M</strong>l<strong>400</strong>, but not<br />

the same as the <strong>351C</strong>. All <strong>of</strong> the blocks<br />

are the same with exception <strong>of</strong> the mainbearing<br />

caps. Some are two-bolt and some<br />

are four-bolt caps. All <strong>429</strong> and 460 blocks<br />

use two-bolt main-bearing caps except for<br />

'70-'71 SCJs and '71 CJs whose blocks<br />

are cast and machined to accept four-bolt<br />

caps in the number-2, -3 and -4 positions.<br />

Because the two-bolt <strong>429</strong> and 460 blocks<br />

are not cast to accept four-bolt caps, they<br />

can't be machined to accommodate them.<br />

With the exception <strong>of</strong> the main-bearing<br />

caps, the only other interchangeability<br />

consideration is deck height, the distance<br />

from the centerline <strong>of</strong> the crankshaft<br />

bearing bores to the block deck surface.<br />

<strong>429</strong>1460 blocks originally had a 10.300-<br />

inch deck height. It was increased 0.010<br />

inch to 10.310 inches in '70-112 for a<br />

slight reduction in compression. A significant<br />

reduction in compression ratio was<br />

made in 1972 by a combination <strong>of</strong> increasing<br />

deck height to 10.322 inches and<br />

increasing cylinder-head combustionchamber<br />

volume. This resulted in a 2-<br />

point drop in compression-from 10.5 to<br />

8.5.<br />

Four-bolt main bearings and deckheight<br />

differences don't present mechanical<br />

interchangeability problems, however<br />

there are other considerations. It would<br />

be a step down to go from a four-bolt<br />

block to a two-bolt one if strength is<br />

what you're after. Because <strong>of</strong> deck heights<br />

and cylinder-head combustion-chamber<br />

volumes, block and cylinder-head combinations<br />

produce different compression<br />

ratios. You should be aware what compression<br />

ratio you'll end up when switching<br />

heads and blocks. This is covered in<br />

more detail later in the chapter.<br />

You'll find <strong>429</strong>1460 cylinder-block<br />

casting numbers under the right-rear<br />

cylinder bank. The number is vertical, or<br />

parallel to the engine block's rear face.<br />

CRANKSHAFTS<br />

335 and 385 Series crankshafts have<br />

one thing in common: all are cast-iron.<br />

Otherwise, their dimensional differences<br />

prevent crankshaft interchanges between<br />

<strong>351C</strong>, 35 1M/<strong>400</strong> and <strong>429</strong>1460 engines.<br />

<strong>351C</strong>-35 1C main- and connecting-rodjournal<br />

diameters are 2.749 inches and<br />

2.31 1 inches, respectively. As with all<br />

<strong>Ford</strong> 351 engines, the stroke is 3 .SO inches<br />

and the engine is externally balanced.<br />

There are differences between 351 C<br />

cranks. Boss and HO crankshafts are<br />

selected for their high-nodularity content.<br />

Nodular cast-iron has its graphite in the<br />

form <strong>of</strong> spheres rather than the flakes <strong>of</strong><br />

grey cast-iron. High nodularity means the<br />

cast-iron contains more nodules, or<br />

spheres, resulting in higher strength. Boss<br />

and HO cranks can be identified by a<br />

Brinell test mark, a spherical indentation<br />

approximately 118-inch wide in the front<br />

or rear face <strong>of</strong> one crankshaft counterweight.<br />

The rough casting surface is ground<br />

smooth in the area tested, so it shouldn't<br />

be too difficult to find the test mark if it<br />

is there. Remember, the test only ensures<br />

the strength <strong>of</strong> the crankshaft. Consequently,<br />

most other <strong>351C</strong> cranks will have<br />

the same strength, the test just proves it<br />

for high-performance applications. Regardless<br />

<strong>of</strong> this one difference, 351 crankshafts<br />

are interchangeable and can be<br />

identified by code number 4M or 4MA on<br />

the side <strong>of</strong> the front counterweight.<br />

<strong>351M</strong>l<strong>400</strong>-35 1M and <strong>400</strong> crankshafts<br />

are the same in all respects with one exception-throw.<br />

Crankshaft throw is the<br />

center distance between the main and<br />

connecting-rod journals. It is half the<br />

stroke. <strong>351M</strong> and <strong>400</strong> strokes are 3.50<br />

inches and 4.00 inches, respectively. Because<br />

stroke is the only exception, <strong>351M</strong><br />

and <strong>400</strong> crankshafts are interchangeable if<br />

<strong>351M</strong> pistons are used with <strong>351M</strong> cranks<br />

and <strong>400</strong> pistons are used with <strong>400</strong> cranks.<br />

Journal diameteis are 3.000 inches and<br />

2.3 11 inches, respectively.<br />

<strong>429</strong>1460-Except for the numbers, the<br />

<strong>429</strong>1460 crankshaft description sounds<br />

like the <strong>351C</strong>. CJ and SCJ versions <strong>of</strong> the<br />

<strong>429</strong> use hardness-tested cranks which can<br />

be identified using the same method as<br />

for the Boss <strong>351C</strong> and HO cranks: a<br />

Brinell test mark on the smoothed face <strong>of</strong><br />

a counterweight. Main-journal and connecting-rod-journal<br />

diameters are 3.00<br />

inches and 2.50 inches, respectively for<br />

both <strong>429</strong> and 460 cranks, however the<br />

460's stroke is 0.30 inch more at 3.85<br />

inches. Because their rods are the same,<br />

you can interchange crankshafts so long<br />

as the pistons are designed to go with the<br />

crank. <strong>429</strong> and 460 code numbers are on<br />

the side <strong>of</strong> the front counterweight.<br />

CONNECTING RODS<br />

All <strong>Ford</strong> 335 and 385 Series engines<br />

use forged-steel connecting rods with 318-<br />

inch connecting-rod bolts.