How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Yes, <strong>429</strong>/460 head bolts are different<br />

length. Long ones are for the bottom row<br />

and the short ones for the top row.<br />

Oil head-bolt threads. Make sure they are clean first. Refer to the table for torque values<br />

and tightening sequence. I recommend retorquing head bolts after you've run the engine.<br />

<strong>To</strong> keep the cylinders free <strong>of</strong> moisture<br />

and dirt, install an old set <strong>of</strong> spark plugs<br />

in your heads, some you won't mind<br />

getting broken. Secure the dip-stick tube.<br />

to the front <strong>of</strong> the right head if you have<br />

a <strong>351C</strong> or <strong>351M</strong>1<strong>400</strong>.<br />

VALVE TRAIN<br />

<strong>To</strong> complete your engine's valve-train<br />

assembly you'!! need 16 valve lifters, pushrods,<br />

rocker arms, fulcrliins and nuts or<br />

bolts. You'll also need your squiri can<br />

full <strong>of</strong> oil or oil additive.<br />

Install the Valve Lifters-Begin putting<br />

the final touch on your valve train by installing<br />

the valve lifters. If you have new<br />

ones, you can install .themlin any order;<br />

used ones must be installed in the bores<br />

they were removed from. Prime your<br />

hydraulic lifters by filling them with oil.<br />

Force oil in the side <strong>of</strong> each lifter with<br />

your squirt can until it comes out the top<br />

oil hole. After priming the lifter, oil its<br />

OD, coat its foot with moly, then install<br />

the lifter in its b0~e.<br />

Pushrods Are Next-With the lifters in<br />

place, slide each pushrod into a head and<br />

on the center <strong>of</strong> a lifter. If you are installing<br />

new pushrods, they can go in<br />

either way. Install old pushrods end-forend-the<br />

end that operated at the lifter<br />

should now be at the rocker arm. You<br />

can tell which end was which by looking<br />

at the wear pattern on the ends. The wear<br />

pattern on the lifter end will be much<br />

smaller than that at the rocker-arm end.<br />

If the ball at the rocker-arm end has worn<br />

so it is egg-shaped, replace the pushrod.<br />

Install the Rocker Arms-<strong>Your</strong> engine will<br />

be equipped with cast-iron rocker arms,<br />

or stamped-steel ones-non-adjustable un-<br />

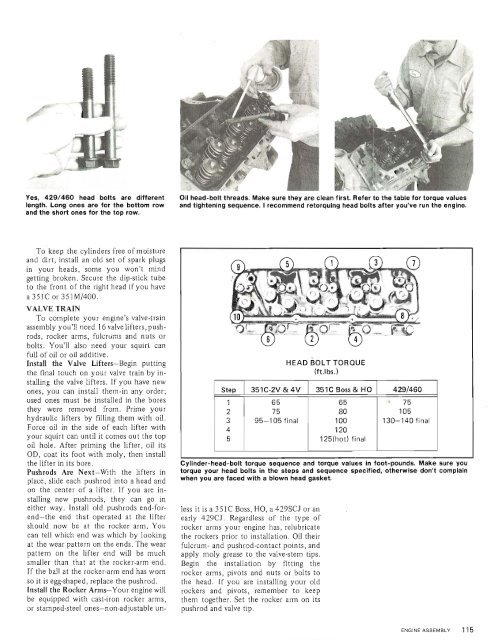

Step 351 C-2V & 4V 351 C Boss & HO <strong>429</strong>1460<br />

1 65 65 = 75<br />

2 75 80 105<br />

3 95-1 05 final 100 130-140 final<br />

4<br />

5<br />

I<br />

Cylinder-head-bolt torque sequence and torque values in foot-pounds. Make sure you<br />

torque your head bolts in the steps and sequence specified, otherwise don't complain<br />

when you are faced with a blown head gasket.<br />

less it is a 351 C Boss, HO, a <strong>429</strong>SCJ or an<br />

early <strong>429</strong>CJ. Regardless <strong>of</strong> the type <strong>of</strong><br />

rocker arms your engine has, relubricate<br />

the rockers prior to installation. Oil their<br />

fulcrum- and pushrod-contact points, and<br />

apply moly grease to the valve-stem tips.<br />

Begin the installation by fitting the<br />

rocker arms, pivots and nuts or bolts to<br />

the head. If you are installing your old<br />

rockers and pivots, remember to keep<br />

them together. Set the rocker arm on its<br />

pushrod and valve tip.<br />

120<br />

125(hol) final