How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DIAGNOSIS<br />

home and dumping the "instant overhaul"<br />

solution down the carburetor. This stuff<br />

really works, loosening the carbon which<br />

then causes these problems. Don't try the<br />

"cure-all" approach to rid your engine <strong>of</strong><br />

carbon. Use the methods I discuss in the<br />

block and cylinder-head reconditioning<br />

chapter. Also, carbon is an effect rather<br />

than a cause. It results from an excessively<br />

rich fuel mixture, oil getting into the<br />

combustion chamber past the piston or<br />

intake-valve stem, very slow driving or<br />

idling for extended periods. If carbonbuildup<br />

causes are cured, the deposits<br />

gradually burn away, negating any need<br />

to tear your engine down to remove the<br />

deposits mechanically.<br />

DIAGNOSIS<br />

Now that I've discussed the types <strong>of</strong><br />

internal problems you may encounter<br />

with your engine and how each may affect<br />

its operation, let's look at how to diagnose<br />

these problems without tearing your<br />

engine -down. On the other hand, your<br />

engine may not have any specific problems,<br />

but you do want to determine if<br />

it's time to rebuild.<br />

Internal Noises-Perhaps your engine has<br />

noises <strong>of</strong> impending disaster coming from<br />

its innards. They may or may not be<br />

accompanied by an increase in fuel or oil<br />

consumption or a reduction in power.<br />

Generally, if the noise is at engine speedonce<br />

for every revolution <strong>of</strong> the crank-the<br />

problem is in the bottom end. Causes are<br />

a broken piston ring, worn connecting-rod<br />

bearing or a worn piston-pin bore<br />

A noise at half engine speed or camshaft<br />

speed, is probably in the valve train,<br />

with one exception. Piston slap occurs<br />

only on the power stroke, consequently it<br />

is also at half speed. If the noise is coming<br />

from the valve train, it could be due to<br />

excessive lash or clearance in the valve<br />

train caused by a collapsed hydraulic<br />

lifter, too much valve clearance or a bent<br />

pushrod. <strong>To</strong> help in determining the<br />

speed <strong>of</strong> the noise, hook up your timing<br />

light and watch the light whle listening<br />

to your engine. If the light flashes in time<br />

with the noise, it's at half engine speed.<br />

<strong>To</strong> assist in listening to what's going<br />

on inside your engine, use a long screwdriver<br />

and press its tip against the block<br />

or cylinder head close to the area where<br />

you suspect the noise to be coming from.<br />

Press your head, or skull just below your<br />

ear against the handle. This will amplify<br />

engine noises. Just make sure you place<br />

the screwdriver against a solid part <strong>of</strong> the<br />

engine to get the best noise transmittal.<br />

Don't put the end <strong>of</strong> the screwdriver<br />

against the valve cover when listening to<br />

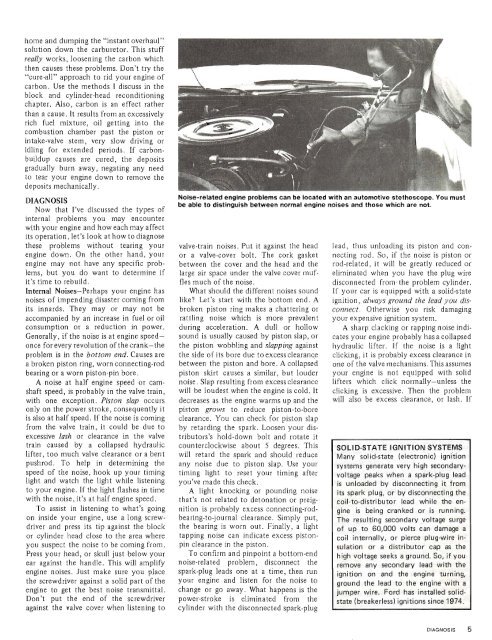

Noise-related engine problems can be located with an automotive stethoscope. You must<br />

be able to distinguish between normal engine noises and those which are not.<br />

valve-train noises. Put it against the head<br />

or a valve-cover bolt. The cork gasket<br />

between the cover and the head and the<br />

large air space under the valve cover muffles<br />

much <strong>of</strong> the noise.<br />

What should the different noises sound<br />

like Let's start with the bottom end. A<br />

broken piston ring makes a chattering or<br />

rattling noise which is more prevalent<br />

during acceleration. A dull or hollow<br />

sound is usually caused by piston slap, or<br />

the piston wobbling and slapping against<br />

the side <strong>of</strong> its bore due to excess clearanc,e<br />

between the piston and bore. A collapsed<br />

piston skirt causes a similar, but louder<br />

noise. Slap resulting from excess clearance<br />

will be loudest when the engine is cold. It<br />

decreases as the engine warms up and the<br />

piston grows to reduce piston-to-bore<br />

clearance. You can check for piston slap<br />

by retarding the spark. Loosen your distributors's<br />

hold-down bolt and rotate it<br />

counterclockwise about 5 degrees. This<br />

will retard the spark and should reduce<br />

any noise due to piston slap. Use your<br />

timing light to reset your timing after<br />

you've made this check.<br />

A light knochng or pounding noise<br />

that's not related to detonation or preig-,<br />

nition is probably excess connecting-rodbearing-to-journal<br />

clearance. Simply put,<br />

the bearing is worn out. Finally, a light<br />

tapping noise can indicate excess pistonpin<br />

clearance in the piston.<br />

<strong>To</strong> confirm and pinpoint a bottom-end<br />

noise-related problem, disconnect the<br />

spark-plug leads one at a time, then run<br />

your engine and listen for the noise to<br />

change or go away. What happens is the<br />

power-stroke is eliminated from the<br />

cylinder with the disconnected spark-plug<br />

lead, thus unloading its piston and connecting<br />

rod. So, if the noise is piston or<br />

rod-related, it will be greatly reduced or<br />

eliminated when you have the plug wire<br />

disconnected from.the problem cylinder.<br />

If your car is equipped with a solid-state<br />

ignition, always ground the lead you disconnect.<br />

Otherwise you risk damaging<br />

your expensive ignition system.<br />

A sharp clacking or rapping noise indicates<br />

your engine probably has a collapsed<br />

hydraulic lifter. If the noise is a light<br />

cliclung, it is probably excess clearance in<br />

one <strong>of</strong> the valve mechanisms. This assumes<br />

your engine is not equipped with solid<br />

lifters which click normally-unless the<br />

cliclung is excessive. Then the problem<br />

will also be excess clearance, or lash. If<br />

SOL1 D-STATE IGNITION SYSTEMS<br />

Many solid-state (electronic) ignition<br />

systems generate very high secondaryvoltage<br />

peaks when a spark-plug lead<br />

is unloaded by disconnecting it from<br />

its spark plug, or by disconnecting the<br />

coil-to-distributor lead while the engine<br />

is being cranked or is running.<br />

The resulting secondary ,voltage surge<br />

<strong>of</strong> up to 60,000 volts can damage a<br />

coil internally, or pierce plug-wire insulation<br />

or a distributor cap as the<br />

high voltage seeks a ground. So, if you<br />

remove any secondary lead with the<br />

ignition on and the .engine turning,<br />

ground the lead to the engine with a<br />

jumper wire. <strong>Ford</strong> has installed solidstate<br />

(breakerless) ignitions since 1974.<br />

-