How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

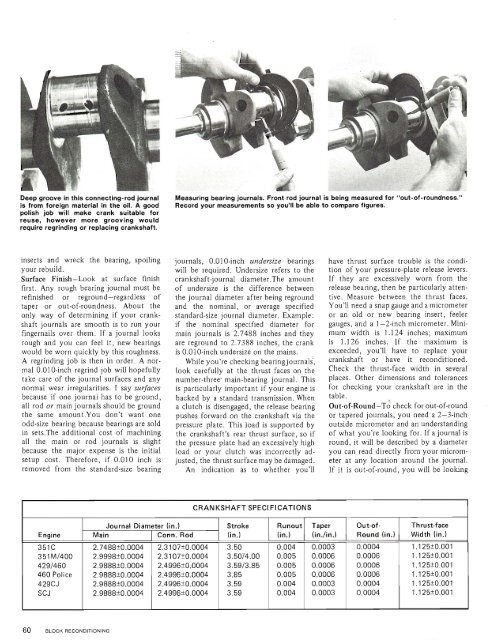

Deep groove in this connecting-rod journal<br />

is from foreign material in the oil. A good<br />

polish job will make crank suitable for<br />

reuse, however more grooving would<br />

require regrinding or replacing crankshaft.<br />

Measuring bearing journals. Front rod journal is being measured for "out-<strong>of</strong>-roundness."<br />

Record your measurements so you'll be able to compare figures.<br />

inserts and wreck the bearing, spoiling<br />

your rebuild.<br />

Surface Finish-Look at surface finish<br />

first. Any rough bearing journal must be<br />

refinished or reground-regardless <strong>of</strong><br />

taper or out-<strong>of</strong>-roundness. About the<br />

only way <strong>of</strong> determining if your crankshaft<br />

journals are smooth is to run your<br />

fingernails over them. If a journal looks<br />

rough and you can feel it, new bearings<br />

would be worn quickly by this roughness.<br />

A regrinding job is then in order. A normal<br />

0.010-inch regrind job will hopefully<br />

take care <strong>of</strong> the journal surfaces and any<br />

normal wear irregularities. I say surfaces<br />

because if one journal has to be ground,<br />

all rod or main journals should be ground<br />

the same amount.You don't want one<br />

odd-size bearing because bearings are sold<br />

in sets.The additional cost <strong>of</strong> machining<br />

all the main or rod journals is slight<br />

because the major expense is the initial<br />

setup cost. Therefore, if 0.010 inch is<br />

removed from the standard-size bearing<br />

journals, 0.01 0-inch undersize bearings<br />

will be required. Undersize refers to the<br />

crankshaft-journal diameter.The amount<br />

<strong>of</strong> undersize is the difference between<br />

the journal diameter after being reground<br />

and the nominal, or average specified<br />

standard-size journal diameter. Example:<br />

if the nominal specified diameter for<br />

main journals is 2.7488 inches and they<br />

are reground to 2.7388 inches, the crank<br />

i's 0.010-inch undersize on the mains.<br />

While you're checking bearingjournals,<br />

look carefully at the thrust faces on the<br />

number-three, main-bearing journal. This<br />

is particularly important if your engine is<br />

backed by a standard transmission. When<br />

a clutch is disengaged, the release bearing<br />

pushes forward on the crankshaft via the<br />

pressure plate. This load is supported by<br />

the crankshaft's rear thrust surface, so if<br />

the pressure plate had an excessively high<br />

load or your clutch was incorrectly adjusted,<br />

the thrust surface may be damaged.<br />

An indication as to whether you'll<br />

have thrust surface trouble is the condition<br />

<strong>of</strong> your pressure-plate release levers.<br />

If they are excessively worn from the<br />

release bearing, then be particularly attentive.<br />

Measure between the thrust faces.<br />

You'll need a snap gauge and a micrometer<br />

or an old or new bearing insert, feeler<br />

gauges, and a I -2-inch micrometer. Minimum<br />

width is 1 .I24 inches; maximum<br />

is 1.126 inches. If the maximum is<br />

exceeded, you'll have to replace your<br />

crankshaft or have it reconditioned.<br />

Check the thrust-face width in several<br />

places. Other dimensions and tolerances<br />

for checking your crankshaft are in the<br />

table.<br />

out-<strong>of</strong>-~ound-T: check for out-<strong>of</strong>-round<br />

or tapered journals, you need a 2-3-inch<br />

outside micrometer and an understanding<br />

<strong>of</strong> what you're looking for. If a journal is<br />

round, it will be described by a diameter<br />

you can read directly from your micrometer<br />

at any location around the journal.<br />

If it is out-<strong>of</strong>-round, you will be looking<br />

CRANKSHAFT SPEC1 FICATIONS<br />

Engine<br />

<strong>351C</strong><br />

351 MI<strong>400</strong><br />

<strong>429</strong>1460<br />

460 Police<br />

<strong>429</strong>CJ<br />

SCJ<br />

Journal Diameter (in.)<br />

Main<br />

Conn. Rod<br />

2.7488+0.0004<br />

2.99980.0004<br />

2.9888f0.0004<br />

2.98880.0004<br />

2.9888+0.0004<br />

2.9888+0.0004<br />

2.3107+0.0004<br />

2.31 07f 0.0004<br />

2.4996f0.0004<br />

2.4996+0.0004<br />

2.4996+0.0004<br />

2.4996+0.0004<br />

Stroke<br />

(in.)<br />

3.50<br />

3.5074.00<br />

3.5913.85<br />

3.85<br />

3.59<br />

3.59<br />

Runout<br />

(in.)<br />

0.004<br />

0.005<br />

0.005<br />

0.005<br />

0.004<br />

0.004<br />

Taper<br />

inin.<br />

0.0003<br />

0.0006<br />

0.0006<br />

0.0006<br />

0.0003<br />

0.0003<br />

Ou t-<strong>of</strong> -<br />

Round (in.)<br />

0.0004<br />

0.0006<br />

0.0006<br />

0.0006<br />

0.0004<br />

0.0004<br />

Thrust-face<br />

Width (in.)<br />

1 .I 25+0.001<br />

1.125f 0.001<br />

1.125f0.001<br />

1.125f0.001<br />

1.125+0.001<br />

1 .I 25f0.001