How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

How To Rebuild Your Ford V-8 351C-351M-400-429-460.pdf - Index of

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CYLINDER HEADS<br />

It's now time to begin buttoning up<br />

the top side, so position your engine upright.<br />

If you are working on a bench or<br />

the floor, your engine will be unstable, so<br />

block it up under the oil-pan flanges or<br />

bell-housing bosses so the engine will sit<br />

level and be stable. If you don't do this<br />

you can count on your engine rolling over,<br />

particularly when it's unbalanced with<br />

one cylinder head installed. If you're<br />

using an engine stand, just make sure the<br />

post is tight.<br />

Get your cylinder heads out <strong>of</strong> storage,<br />

the 2 head gaskets from your gasket set<br />

and the head bolts-20 grade-8 bolts to be<br />

exact. All <strong>351C</strong> and <strong>351M</strong>/<strong>400</strong> head bolts<br />

are the same saize: 1/2-13 x 4-5/16 inches<br />

long. The top <strong>429</strong>1460 head bolts are<br />

shorter than those for the bottom row.<br />

Their sizes are 9/16-12 x 4-318 inches<br />

long and 9/16-12 x 5-118 inches long,<br />

respectively.<br />

Clean the Head-Gasket Surface-<strong>To</strong> ensure<br />

the best possible head-gasket seal, clean<br />

the cylinder-head and cylinder-block gasket<br />

surfaces with solvent. Check to make<br />

sure all cylinder-head locating dowel pins<br />

are in place. They are a must as they<br />

accurately locate the heads on the block<br />

deck surface. If they are missing, replace<br />

them. Do this by inserting the straight<br />

end in the block with the chamfered, or<br />

tapered end projecting outward and tap it<br />

into place. You'll feel the pin bottom in<br />

its hole when it's fully installed.<br />

For pre-'72 engines having high compression<br />

ratios, you'll need the best<br />

sealing head gaskets available. Use Felpro's<br />

"Permatorque" or Victor's "Victorcor"<br />

head gaskets. If you use either <strong>of</strong> these<br />

gaskets, your block and cylinder-head<br />

gasket surfaces must be in the best <strong>of</strong><br />

condition-free from distortions and<br />

smooth. These gaskets are very hard, and<br />

consequently can't conform to surface<br />

irregularities. Because head gaskets are<br />

included in a complete engine-rebuild<br />

gasket set, the set you purchase should<br />

include these head gaskets.<br />

Coat the Head Caskets-Head gaskets can<br />

be installed as is, however I like a little<br />

added insurance. One <strong>of</strong> the most common<br />

and easiest to appy "sealers" is<br />

aluminum paint from a spray can. Evenly<br />

coat both sides <strong>of</strong> your head gaskets with<br />

it. After the paint has dried, position the<br />

gaskets on the engine block by locating<br />

them on the dowel pins with the FRONT<br />

designation on the gaskets to the front.<br />

If you get the gaskets on wrong, you'll be<br />

wondering why your cylinder heads are<br />

melting and your idiot lightlgage is not<br />

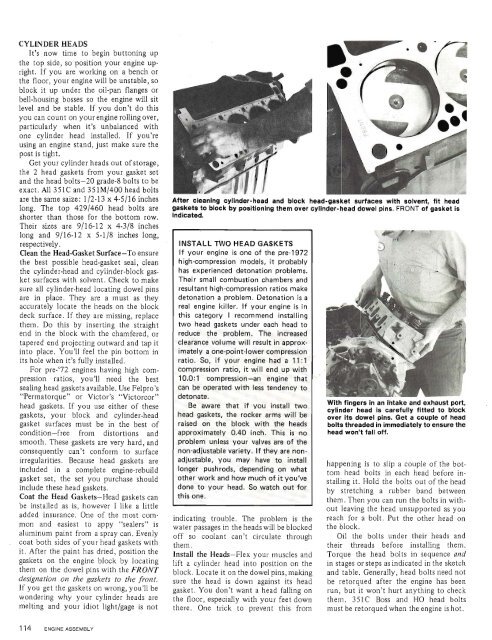

After cleaning cylinder-head and block head-gasket surfaces with solvent, fit head<br />

gaskets to block by positioning them over cylinder-head dowel pins. FRONT <strong>of</strong> gasket is<br />

indicated.<br />

INSTALL TWO HEAD GASKETS<br />

If your engine is one <strong>of</strong> the pre-1972<br />

high-compression models, it probably<br />

has experienced detonation problems.<br />

Their small combustion chambers and<br />

resultant high-compression ratios make<br />

detonation a problem. Detonation is a<br />

real engine killer. If your engine is in<br />

this category I recommend installing<br />

two head gaskets under each head to<br />

reduce the problem. The increased<br />

clearance volume will result in approximately<br />

a one-point-lower compression<br />

ratio. So, if your engine had e 11 : 1<br />

compression ratio, it will end up with<br />

10.0: 1 compression-an engine that<br />

can be operated with less tendency to<br />

detonate.<br />

Be aware that if you install two<br />

head gaskets, the rocker arms will be<br />

raised on the block with the heads<br />

approximately 0.40 inch. This is no<br />

problem unless your valves are <strong>of</strong> the<br />

non-adjustable variety. If they are nonadjustable,<br />

you may have to install<br />

longer pushrods, depending on what<br />

other work and how much <strong>of</strong> it you've<br />

done to your head. So watch out for<br />

this one.<br />

indicating trouble. The problem is the<br />

water passages in the heads will be blocked<br />

<strong>of</strong>f so coolant can't circulate through<br />

them.<br />

Install the Heads-Flex your muscles and<br />

lift a cylinder head into position on the<br />

block. Locate it on the dowel pins, making<br />

sure the head is down against its head<br />

gasket. You don't want a head falling on<br />

the floor, especially with your feet down<br />

there. One trick to prevent this from<br />

-<br />

Wlth fingers In an ihtake and exhaust port,<br />

cylinder head is carefully fitted to block<br />

over its dowel pins. Get a couple <strong>of</strong> head<br />

bolts threaded in immediately to ensure the<br />

head won't fall <strong>of</strong>f.<br />

happening is to slip a couple <strong>of</strong> the bottom<br />

head bolts in each head before installing<br />

it. Hold the bolts out <strong>of</strong> the head<br />

by stretching a rubber band between<br />

them. Then you can run the bolts in without<br />

leaving the head unsupported as you<br />

reach for a bolt. Put the other head on<br />

the block.<br />

Oil the bolts under their heads and<br />

their threads before installing them.<br />

<strong>To</strong>rque the head bolts in sequence and<br />

in stages or steps as indicated in the sketch<br />

and table. Generally, head bolts need not<br />

be retorqued after the engine has been<br />

run, but it won't hurt anything to check<br />

them. <strong>351C</strong> Boss and HO head bolts<br />

must be retorqued when the engine is hot.